WIKA 432.36 User Manual

Page 9

6. Commissioning, operation

Mechanical connection

In accordance with the general technical regulations for pressure gauges (e.g.

EN 837-2 "Selection and installation recommendations for pressure gauges").

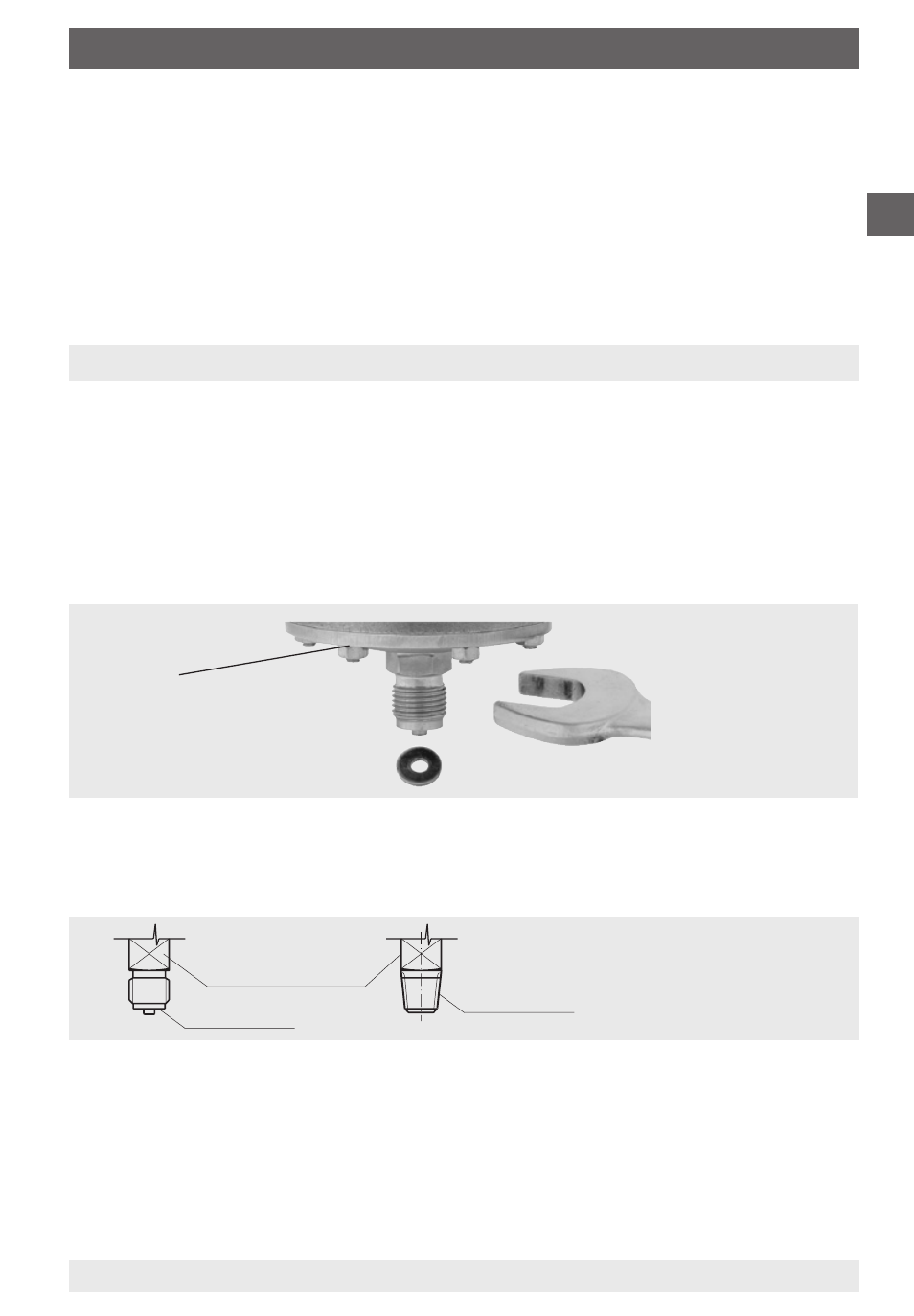

When screwing gauges in, the force required for this must not be applied through

the case, but rather through the spanner flats (using a suitable tool) provided for

this purpose on the square shaft of standard connections.

Correct sealing of pressure gauge connections with parallel threads

must be

made using suitable sealing rings, sealing washers or WIKA profile seals. The

sealing of tapered threads (e.g. NPT threads) is made by providing the thread

with additional sealing material such as, for example, PTFE tape (EN 837-2).

The torque depends on the seal used. Connecting the gauge using a clamp

socket or a union nut is recommended, so that it is easier to orientate the gauge

correctly. When a blow-out device is fitted to a pressure gauge, it must be

protected against being blocked by debris and dirt.

With safety pressure gauges (see dial symbol k) ensure that the free space

behind the blow-out back is at least 15 mm.

WIKA operating instructions pressure gauge model 4 per ATEX

9

2080276.04 12/2010 GB/D/F/E

GB

Installation with

open-ended

spanner

Flange connection 1)

1) The screw connection of the flange

must not be opened

Sealing in the

thread

Spanner flats

Sealing face

6. Commissioning, operation

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g.

change in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +70 °C (optional: -40 … +70 °C)