Instruction manual ni-221e – WIKA MAB User Manual

Page 3

INSTRUCTION MANUAL

NI-221E

Rev. 1 11/02

If the instrument has been ordered with a specific cali-

bration, it is a good rule to check the calibration values

marked on the relevant adhesive label, prior to installation.

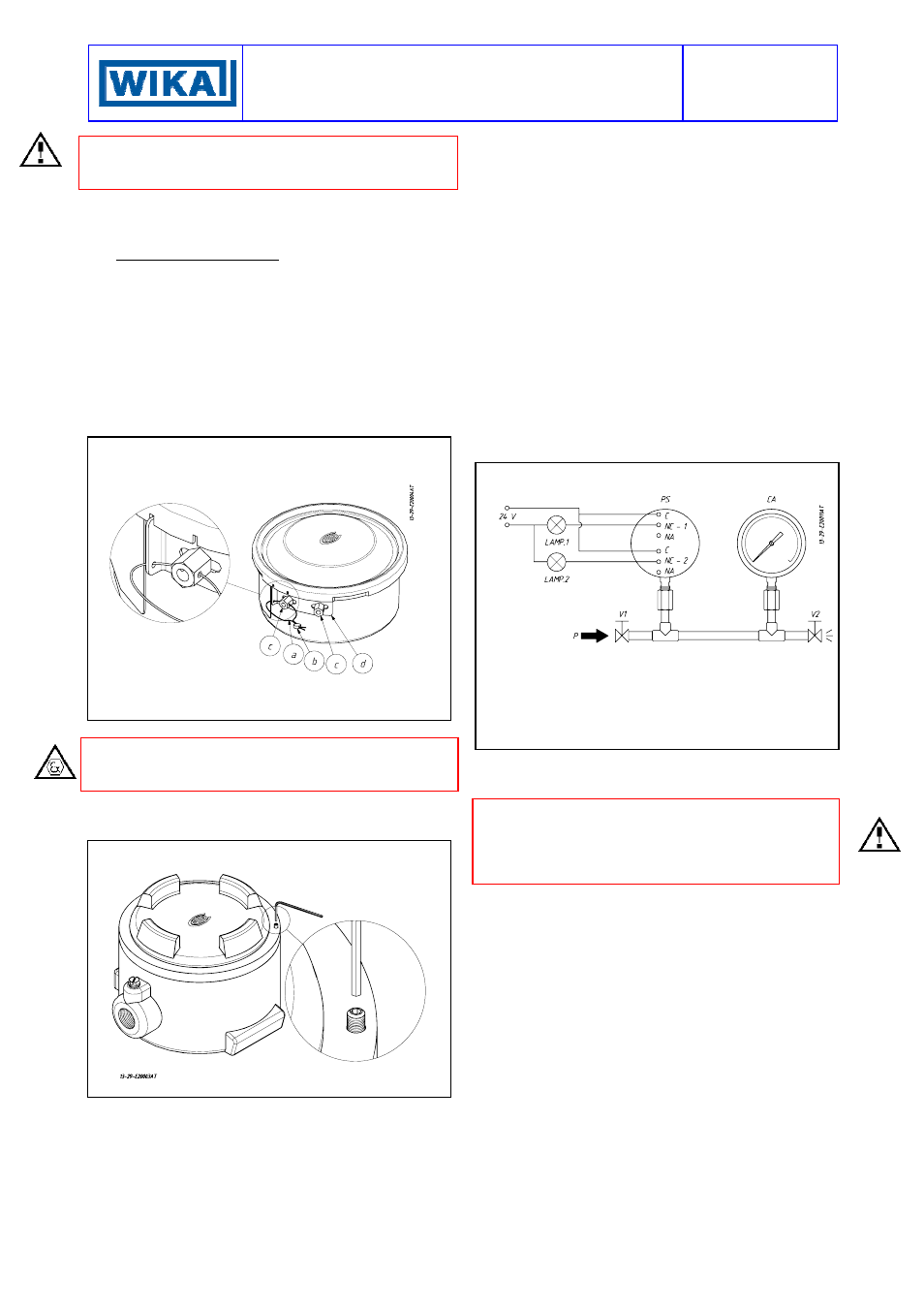

The position of the adjustment screw is given in figure 2.

The effect that the direction of rotation of the adjustment

screw has is described on the adhesive plate.

5

SET POIT CALIBRATION

In order to proceed with the calibration and the periodical

functional verification of the instrument a suitable calibra-

tion circuit (fig. 4) and an adequate pressure source is

required.

5.1 PRELIMINARY OPERATIONS

5.1.1 Weatherproof pressure switches (Series MW)

Remove the blocking device fixed to the side of the in-

strument case (Fig. 3).

Remove the cover by rotating it in an anticlockwise direc-

tion.

Fig. 3 -

Weatherproof pressure switch blocking device

a - Plumbing wire

b - Plumbing

c - Nut

d - Blocking bracket

5.1.2 Explosionproof pressure switches (Series MA)

CAUTION: do not open the cover of explosionproof pres-

sure switches (Series MA) when energized, in explosive

atmospheres.

Loosen the locking headless screw situated on the cover

using a 1,5 hexagonal key then unscrew the cover. (Fig.

4).

Fig. 4 -

Explosionproof pressure switch blocking device

5.2 CALIBRATION CIRCUIT AND OPERATIONS

Prepare the control circuit as indicated in Fig.5.

The warning lamps should be connected to contact 1 or 2

in the NO or NC position according to the required contact

action.

Connection of C and NO terminals

• If the circuit is open at the working pressure, the switch

closes the circuit as the pressure increases when the

desired value is reached.

• If the circuit is closed at the working pressure, the switch

opens the circuit as the pressure decreases when the

desired value is reached.

Connection of C and NC terminals

• If the circuit is closed at the working pressure, the switch

opens the circuit as the pressure increases when the

desired value is reached.

• If the circuit is open at the working pressure, the switch

closes the circuit as the pressure decreases when the

desired value is reached.

The test instrument should have a measurement range

approximately equal to or slightly wider than the pressure

switch range and should have an accuracy consistent with

the precision required to calibrate the set point.

The pressure switch must be mounted in the normal in-

stallation position, i.e. with the pressure connection point-

ing downwards.

Fig. 5 -

Calibration circuit

PS -

Pressure switch

CA -

Test pressure gauge

V1 -

Inlet valve

V2 -

Discharge valve

P -

Pressure source

Test fluid:

air for P

≤ 10 bar

water for P > 10 bar

Avoid forcing the elastic support of the microswitch by

hand or with tools. This could affect the instrument func-

tioning.

CAUTION: if the switch is of the kind with adjustable dead

band (letter R in the contact codes) before proceeding

with the following operations it is necessary to proceed

with the adjustment of the dead band (see attachment NI-

706).

Increase the pressure in the circuit up to the desired set

point value for the first microswitch. Use a wide bladed

screwdriver, as indicated on the adhesive plate, until the

relative lamp turns on (or turns off).

- If the instrument is equipped with only one contact the

calibration is complete.

- If it is equipped with two contacts continue in the follow-

ing manner.

Vary the pressure until the desired set point value for the

second microswitch is reached. Act on the adjustment

screw of the second contact

.

Repeat calibrating operations on the first contact, then on

the second contact, until the required set point precision is

obtained. This is necessary due to the reciprocal influence

which the microswitches have on the sensitive element of

the instrument.

Check the calibration values (varying the pressure in the

circuit accordingly) and record them on the adhesive plate

using a pen with indelible ink.

5.3 FINAL OPERATIONS

Disconnect the instrument from the calibration circuit.