Instruction manual ni-222e – WIKA BWX User Manual

Page 6

INSTRUCTION MANUAL

NI-222E

Rev. 1 12/02

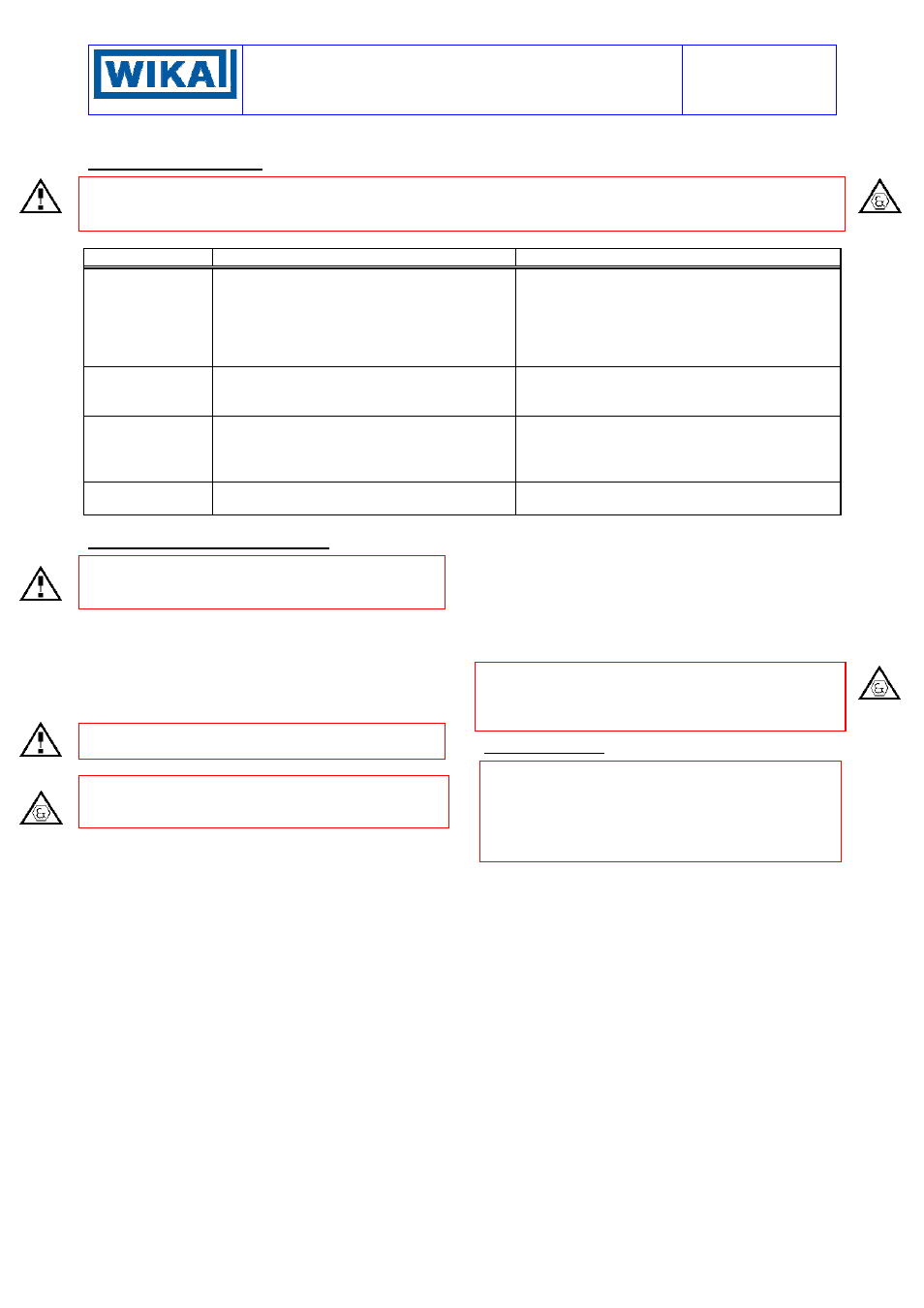

10 - TROUBLESHOOTING

IMPORTANT NOTE: operations involving replacement of essential components must be carried out at our work-

shop, especially for instruments with explosionproof certificate; this is to guarantee the user the total and cor-

rect restoration of the product original characteristics.

MALFUNCTION PROBABLE

CAUSE

REMEDY

Set point shift

Permanent deformation of the sensitive

element due to fatigue or non-tolerated over-

ranges.

Variation of the elastic features of the sensi-

tive element due to its chemical corrosion.

Recalibrate or replace the sensitive element.

Recalibrate or replace the sensitive element

with another made of a suitable material. If

necessary apply a fluid separator.

Slow response

Clogged or obstructed connection line.

Root valve partially closed.

Too viscous fluid.

Check and clean line.

Open valve.

Provide instrument with suitable fluid separator.

No actuation or

undue actuation

Root valve closed.

Microswitch contacts damaged.

Loosened electrical joints.

Interrupted or short-circuited electrical line.

Open the valve

Replace the Microswitch.

Check all electrical joints.

Check the conditions of the electrical line.

Undue actuation

Accidental shocks or excessive mechanical

vibrations.

Modify the mounting.

11 - STOPPING AND DISMOUNTING

Before proceeding with these operations ensure that the

plant or machines have been put into the conditions

foreseen to allow these operations.

With reference to figures 7 and 8

Remove the power supply (signal) from the electrical

line.

Close the root valve (6) and open the drain

Remove the plug (2), open the valve (3) and wait until

the process fluid has drained from the tubing through the

drain.

Do not dispose of the process fluid into the environment,

if this can cause pollution or damage to people.

Unscrew the three-piece joint (8).

CAUTION: do not open the cover of explosionproof

pressure switches (Series BAX) when energized, in

explosive atmospheres.

Unscrew the three-piece joint (10) (electrical cable tub-

ing).

Remove the instrument cover and disconnect the electri-

cal cables from the terminal block and earth screws.

Remove the screws fixing the case to the panel (or pipe)

and remove the instrument, taking care to slide the elec-

trical conductors out from the case.

Replace the instrument cover. Insulate and protect the

conductors remaining on the plant. Temporarily plug the

tubing (4).

In case of explosionproof instruments (Series BAX) it is

recommended to follow - at least – the standard EN-

60079-17 for the withdrawal from service of electrical

apparatus.

12 - DEMOLITION

The instruments are mainly made of stainless steel and

aluminium and therefore, once the electrical parts have

been dismounted and the parts coming into contact with

fluids which could be harmful to people or the environ-

ment have been properly dealt with, they can be

scrapped.