Instruction manual ni-222e – WIKA BWX User Manual

Page 4

INSTRUCTION MANUAL

NI-222E

Rev. 1 12/02

• If the circuit is open at the working pressure, the

switch closes the circuit as the pressure decreases

when the desired value is reached.

The test instrument should have a measurement range

approximately equal to or slightly wider than the pressure

switch range and should have an accuracy consistent

with the precision required to calibrate the set point.

The pressure switch must be mounted in the normal

installation position, i.e. with the pressure connection

pointing downwards.

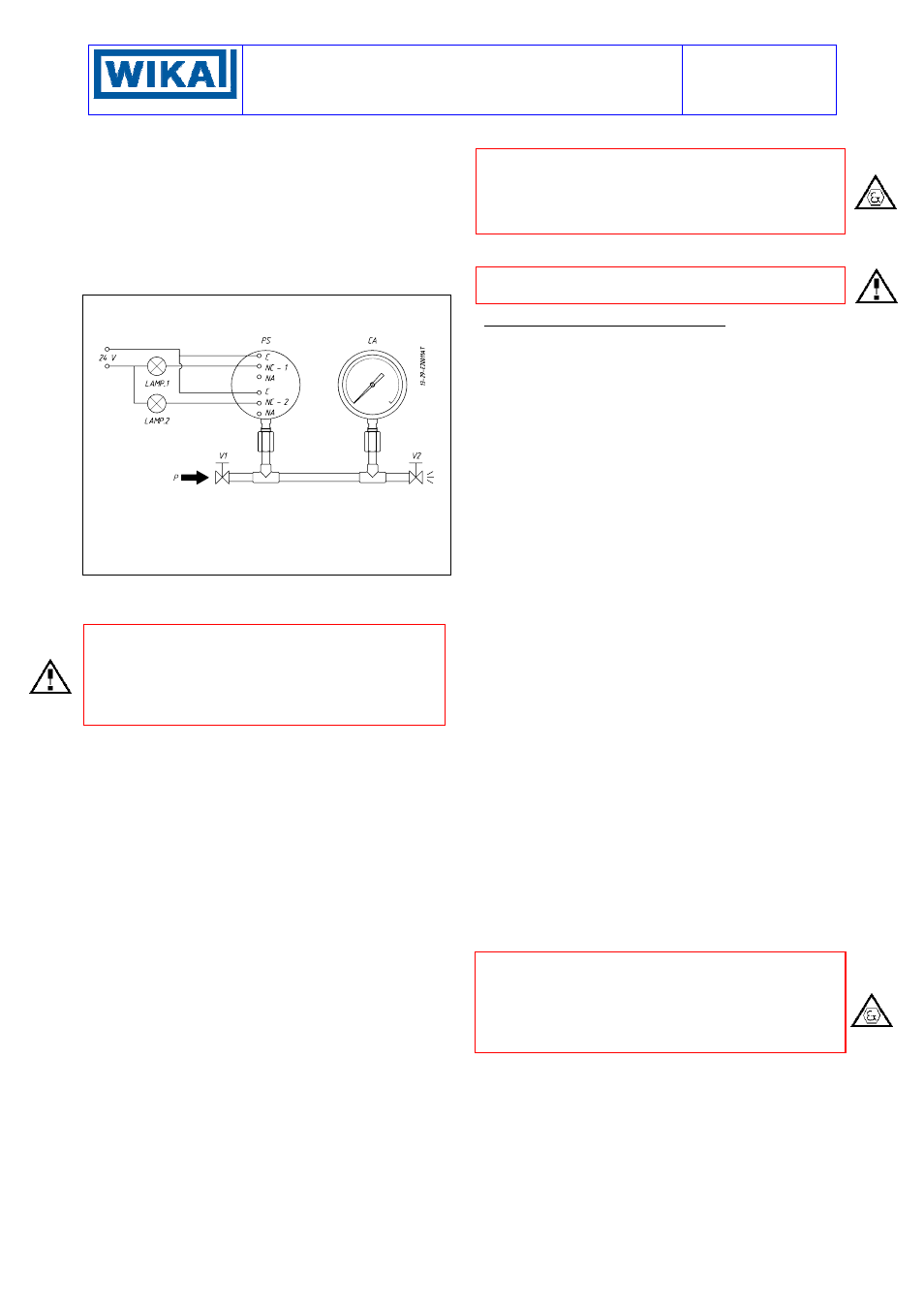

Fig. 5 -

Calibration circuit

PS -

Pressure switch

CA -

Test pressure gauge

V1 -

Inlet valve

V2 -

Inlet valve

P -

Pressure source

Test fluid:

air for P

≤ 10 bar

water for P > 10 bar

Avoid forcing the elastic support of the microswitch by

hand or with tools. This could affect the instrument func-

tioning.

CAUTION: if the switch is of the kind with adjustable

dead band (letter R in the contact codes) before pro-

ceeding with the following operations it is necessary to

proceed with the adjustment of the dead band (see at-

tachment NI-705 for model BWXUR and NI-704 for

model BAXUR)

Increase the pressure in the circuit up to the desired set

point value for the first microswitch.

Use a wide bladed screwdriver, as indicated on the ad-

hesive plate, until the relative lamp turns on (or turns off).

- If the instrument is equipped with only one contact the

calibration is complete.

- If it is equipped with two contacts continue in the fol-

lowing manner.

Vary the pressure until the desired set point value for the

second microswitch is reached.

Act on the adjustment screw of the second contact.

Repeat former operations on the first contact, then op-

erations on the second contact, until the required set

point precision is obtained. This is necessary due to the

reciprocal influence which the microswitches have on the

sensitive element of the instrument.

Check the calibration values (varying the pressure in the

circuit accordingly) and record them on the adhesive

plate using a pen with indelible ink.

5.3 FINAL OPERATIONS

Disconnect the instrument from the calibration circuit

Weatherproof pressure switches (Series BWX)

Take the cover, ensure that the sealing gasket is cor-

rectly fitted into its seat, and insert the cover onto the

case, with the blocking gap positioned in correspon-

dence to the blocking bracket. Turn the cover clockwise

closing it tightly. Mount the adjustment screw access

plate, then the blocking device as in Fig. 3.

Explosionproof pressure switches (Series BAX).

Insert the closure plugs of the adjustment screw access

holes, block them using the internal device and if nec-

essary seal them with plumbing. Screw on the cover and

block it using the headless screw with which it is

equipped (Fig. 4).

Replace the supplied protection caps on the pressure

attachment and cable conduit.

IMPORTANT: the protection caps should only be defini-

tively removed during the connection steps (see §6).

6 - MOUNTING AND CONNECTIONS

6.1 MOUNTING

Surface mount the instrument by means of the holes

provided, or pipe mount using the appropriate bracket

(see Fig. 9). The chosen position must be such that

vibrations, the possibility of shocks or temperature

changes are within tolerable limits. The above also ap-

plies to direct mounting. With gas or vapour process

fluid, the instrument must be positioned higher than the

pipe inlet (see Fig. 8). With a liquid process fluid, the

instrument can be positioned higher or lower, indiffer-

ently (see Fig. 7 e 8). ). In this case, during set point

calibration the negative or positive head must be taken

into account (distance h in fig.7 and 8).

6.2 PRESSURE CONNECTIONS

For a correct installation it is necessary to:

Mount a shut-off valve with drain (root valve) on the

process tube to allow the instrument to be excluded and

the connection tubing to be drained. It is recommended

that said valve has a capstan-blocking device aimed at

preventing it being activated casually and without au-

thorisation.

Mount a service valve near the instrument to permit

possible functional verification on site. It is recom-

mended that the service valve is closed with a plug to

prevent the outlet of the process fluid caused by the

incorrect use of said valve.

Mount a three-piece joint onto the threaded attachment

of the instrument to permit the easy mounting or removal

of the instrument itself.

Carry out the connection using a flexible tube in such a

way that variations in the temperature of the tube itself

do not force the instrument attachment.

Ensure that all the pressure connections are airtight. It is

important that there are no leakage in the circuit.

Close the root valve and the relative drain device.

Close the service valve using a safety plug.

6.3 ELECTRICAL CONNECTIONS

It is recommended to carry out the electrical connections

according to the applicable standards. In case of explo-

sionproof instruments (Series BAX) see also the Stan-

dard EN-60079-14. If the electrical connection is carried

out in a protected tube, it shall be made so that conden-

sate is prevented from entering instrument enclosure.

The arrangement shown in Fig. 7 or 8 is therefore rec-

ommended.