Combustible wall and masonry – M&G DuraVent DuraLiner® User Manual

Page 9

9

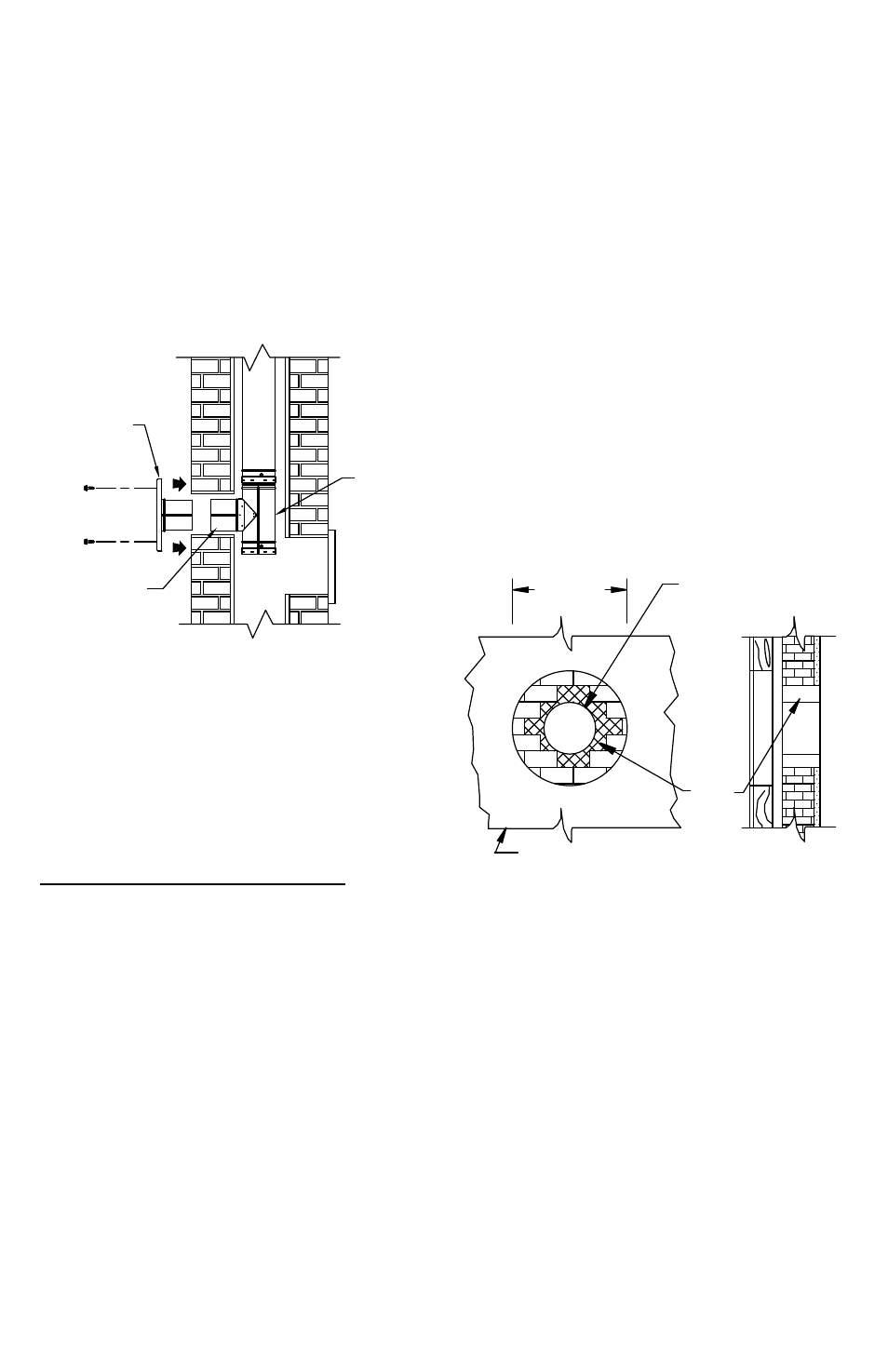

STEP THREE: Using DuraVent's Masonry

Thimble with Slip Connector, connect slip

connector to Tee branch with the pre-

formed buttons. Slide Masonry thimble to

slip connector and attach black trim plate to

masonry surface using screws. (Fig.13)

for the Wall Pass-Through to fit through the

combustible wall. Again, before cutting this

hole, check the clearance from the top of the

Connector Pipe to the ceiling.

STEP TWO: If the minimum clearance to the

combustible ceiling is met, then drill a 3/8 inch

diameter hole through the combustible wall, at

the center of the 14-1/2 inch circle you have

inscribed. With a punch, mark the center on

the masonry behind the wall. Cut the 14-1/2

inch diameter hole in the wall. If it is necessary

to cut through studs, additional framing should

be installed to maintain the structural integrity

of the wall (Fig.14).

STEP THREE: Using the center mark

Figure 14

SIDE VIEW

FRONT VIEW

GROUT

6 1/2 OR 8 1/2 DIA.

14 1/2

STUDS ON 16-INCH CENTERS

Figure 13

Tee

MASONRY

THIMbLe

ANCHOR

SCReWS

SLIP CONNeCTOR

FROM MASONRY

THIMbLe

ACCeSS

DOOR FOR

CLeANOUT

STEP FOUR:

Finish installation to appliance using connector

pipe, maintaining required clearances.

Combustible Wall and Masonry

(See completed installation in Fig.15)

STEP ONE: If no hole exists in the masonry,

mark the center point for the location of

penetration into the combustible wall. before

cutting or drilling, check the clearance between

the top of the connecting pipe to the ceiling,

as shown in Fig.12, Fig.15. The minimum

clearance to the ceiling for single wall pipe is

18", and for DuraVent DVL Connector Pipe, 8".

Scribe a circle from the center point on the wall

with a 7-1/4 inch radius (14-1/2 inch diameter)

(Fig.14). This is the size of the hole required

punched into the masonry, inscribe a circle

of 3- 1/4 inch radius (6-1/2 inch diameter),

or 4-1/4 inch radius (8-1/2 inch diameter),

depending upon whether 6 inch or 8 inch

Dura-Liner Pipe is used. Remove bricks as

necessary to approximate a circle. Smooth

out the circumference of the hole with high-

temperature grout or mortar. Maintain the

concentricity of this hole with the hole cut in

the combustible wall. The completed hole

should look like (Fig.14).