Extend-a-cap installation – M&G DuraVent DuraLiner® User Manual

Page 11

11

Check the appliance manufacturer’s

installation instructions to ensure proper

positioning with relation to combustibles.

Complete the installation with Connector Pipe

Sections and Fittings as required. Inspect the

completed job to ensure it is done in a careful

and workman-like manner.

EXTEND-A-CAP INSTALLATION

The cap may be installed on both round and

oval rigid systems.

STEP ONE: Center the base plate on the top

of the masonry chimney (Fig.18). Trim to fit

the chimney as required. Use non-hardening

sealant to seal the base plate to the masonry

chimney, but this can be done after the liner

has been lowered into place. Anchors or

screws are recommended but not required, as

the base plate will ultimately be supporting the

entire weight of the installation.

STEP TWO: Assemble and position the clamp

assembly on top of the base (Fig.6, Fig.18).

Adjust the bolts on the clamp assembly so that

pipe sections will just pass through the clamp.

STEP THREE: Once the desired length of

liner has been achieved, tighten the clamp

assembly bolts, until the system is firmly

supported by the base. There should not be a

Duraliner pipe joint above the clamp assembly.

Attach the storm collar, and seal with non-

hardening silicone (500°F) sealant. Install Cap

to pipe, using #8 sheet metal screws. (Fig.19).

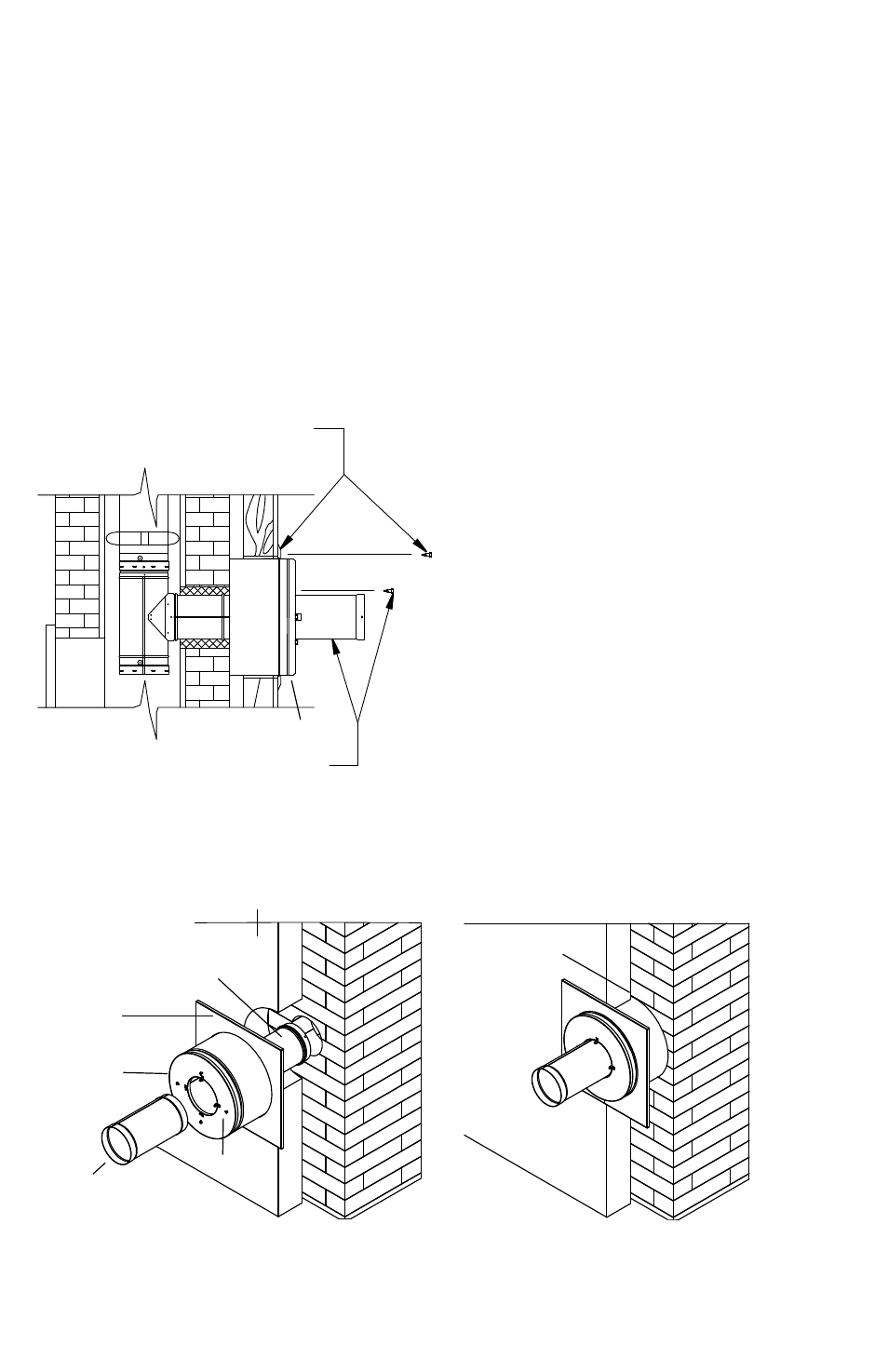

Figure 16

Figure 17

2" INTO THe ROOM

COMbUSTIbLe WALL

10" LONg

RIgID PIPe SeCTION

INSULATeD WALL

PASS THROUgH

TRIM PLATe

ADjUSTAbLe

SLeeVe

WALL PASS

THROUgH AgAINST

MASONRY

HARDWARe

TRIM COLLAR

AND SCREWS

(COMPONENTS OF

WALL PASS-THRU

ASSEMBLY)

RIGID PIPE

AND SCREWS

(COMPONENTS OF

WALL PASS-THRU

ASSEMBLY)