Troubleshooting – Alto-Shaam Cook & Hold Oven Electronic Control 500-TH/III User Manual

Page 30

pg

. 28

TH/III

InsTallaTIon

/

operaTIon

/

servIce

manual

S E R V I c E

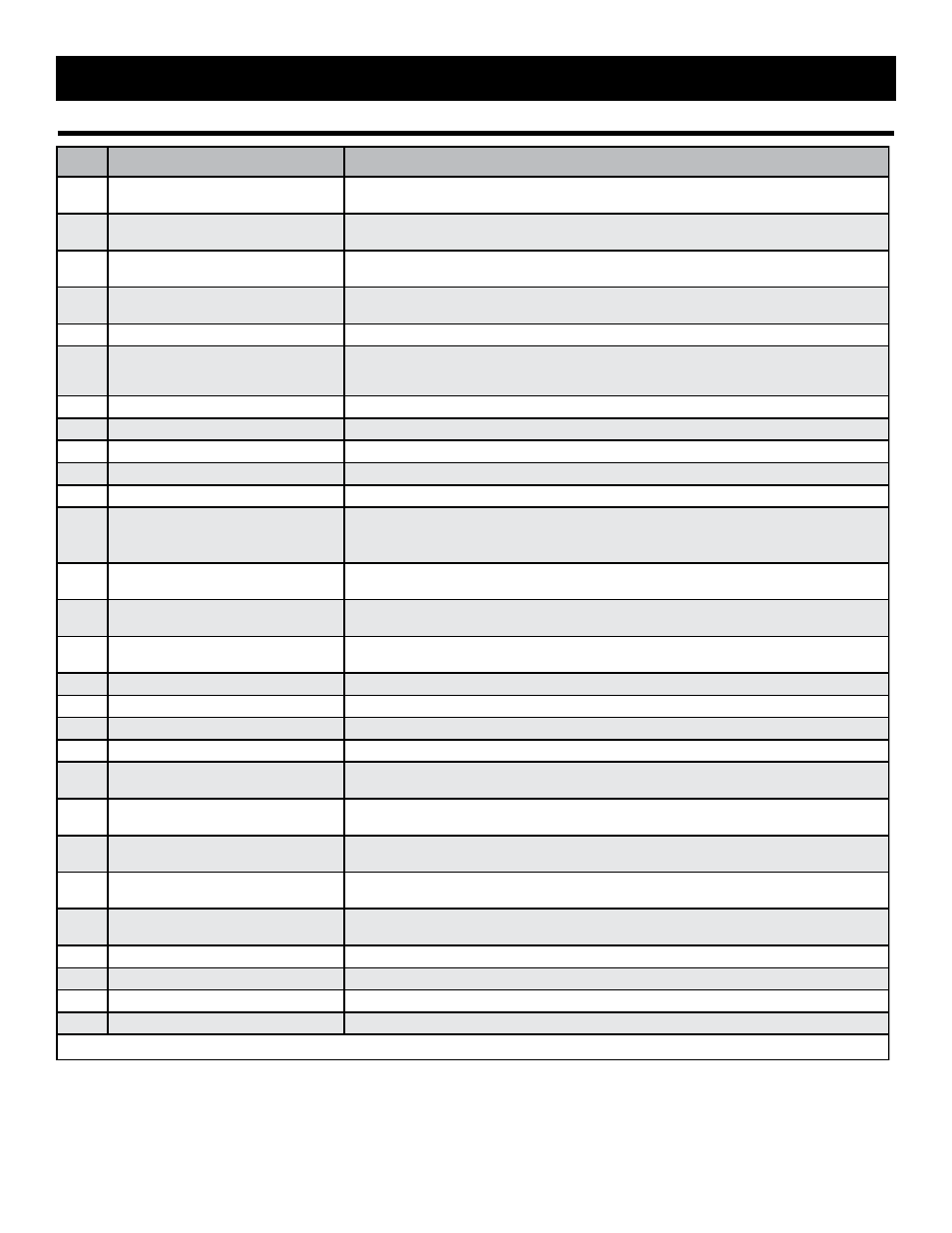

TROUBLEShOOTINg

code description

possible cause

E-10

cavity air sensor shorted

Cavity air sensor reading < 5°F. Verify sensor integrity.

See sensor test instructions below.

E-11

cavity air sensor open

Cavity air sensor reading > 517°F. Verify sensor integrity.

See sensor test instructions below.

E-20

product probe is shorted

Oven will cook in time only

Product probe reading < 5°F. Verify sensor integrity.

See sensor test instructions below.

E-21

product probe is open

Oven will cook in time only

Product Probe reading > 517°F. Verify sensor integrity.

See sensor test instructions below.

E-30

Under temperature

Unit has not reached (set-point - 25°F) for more than 90 minutes.

E-31

Over temperature

Unit has been higher than 25°F above the maximum cavity set-point for

more than 2 minutes. Note: Holding Cabinets with this error code are

more than 145°F higher than the maximum set-point.

E-50

Temp. measurement error

Contact factory.

E-51

Temp. measurement error

Contact factory.

E-60

Real time clock error

Data set to factory default. Ensure that date and time are correct if applicable.

E-61

Real time clock error

Contact factory.

E-64

clock is not oscillating

Contact factory.

E-70

configuration connector

error (dIp switch)

Refer to wiring diagram for the particular model and ensure dip switches on

the control match the settings called out on the WD. If the dip switch settings

are correct according to the print replace the control.

E-78

Voltage low

Voltage below 90 VAC on a 125 VAC unit, or below 190 VAC on a

208-240 VAC unit. Correct voltage.

E-79

Voltage high

Voltage over 135 VAC on a 125 VAC unit, or over 250 VAC on a

208-240 VAC unit. Correct voltage.

E-80

EEpROM Error

Ensure that all temperatures and times are properly set.

Contact factory if problem persists.

E-81

EEpROM Error

Contact factory.

E-82

EEpROM Error

Contact factory.

E-83

EEpROM Error

Contact factory.

E-85

EEpROM Error

All timers, if previously on, are now off. Possible bad EEPROM.

E-86

EEpROM Error

Stored HACCP memory corrupted. HACCP Address reset to 1. Possible bad

EEPROM. Contact factory if problem persists.

E-87

EEpROM Error

Stored offsets corrupted. Offsets reset to 0. Control may need a recalibration.

Possible bad EEPROM. Contact factory if problem persists.

E-88

EEpROM Error

All timer set-points are reset to 1 minute. Timers, if previously on, are now

off. Possible bad EEPROM.

E-90

Button stuck

A button has been held down for >60 seconds. Adjust control. Error will

reset when the problem has been resolved.

E-dS

datakey error

Datakey digital signature incompatible. Cycle power, and install compatible

Datakey if error persists.

E-dT

datakey error

Datakey incompatible with control. Install compatible Datakey.

E-dU

datakey unplugged

Install Datakey and cycle power to control to clear error.

dLto

datalogger has timed out

Cycle power. Contact factory if error persists.

dLSd Micro Sd card not plugged in

Plug in SD card and cycle power. Contact factory if error persists.

Note: If in doubt, always cycle the power to the control and contact factory if the problem persists.

To test probe and air sensor:

Tes t probe and air sensor by placing sensor in ice water bath and using an ohmmeter set on the ohm scale. The

reading should be 100 ohms resistance. If it is more than 2 ohms higher or lower, sensor needs to be replaced

.