Electrical-line voltage, Caution, Warning – Comfort-Aire HWW120 User Manual

Page 15: Hww electrical data

14

Heat Controller, Inc.

WATER-TO-WATER (HWW) SERIES

Installation & Operation

Electrical-Line Voltage

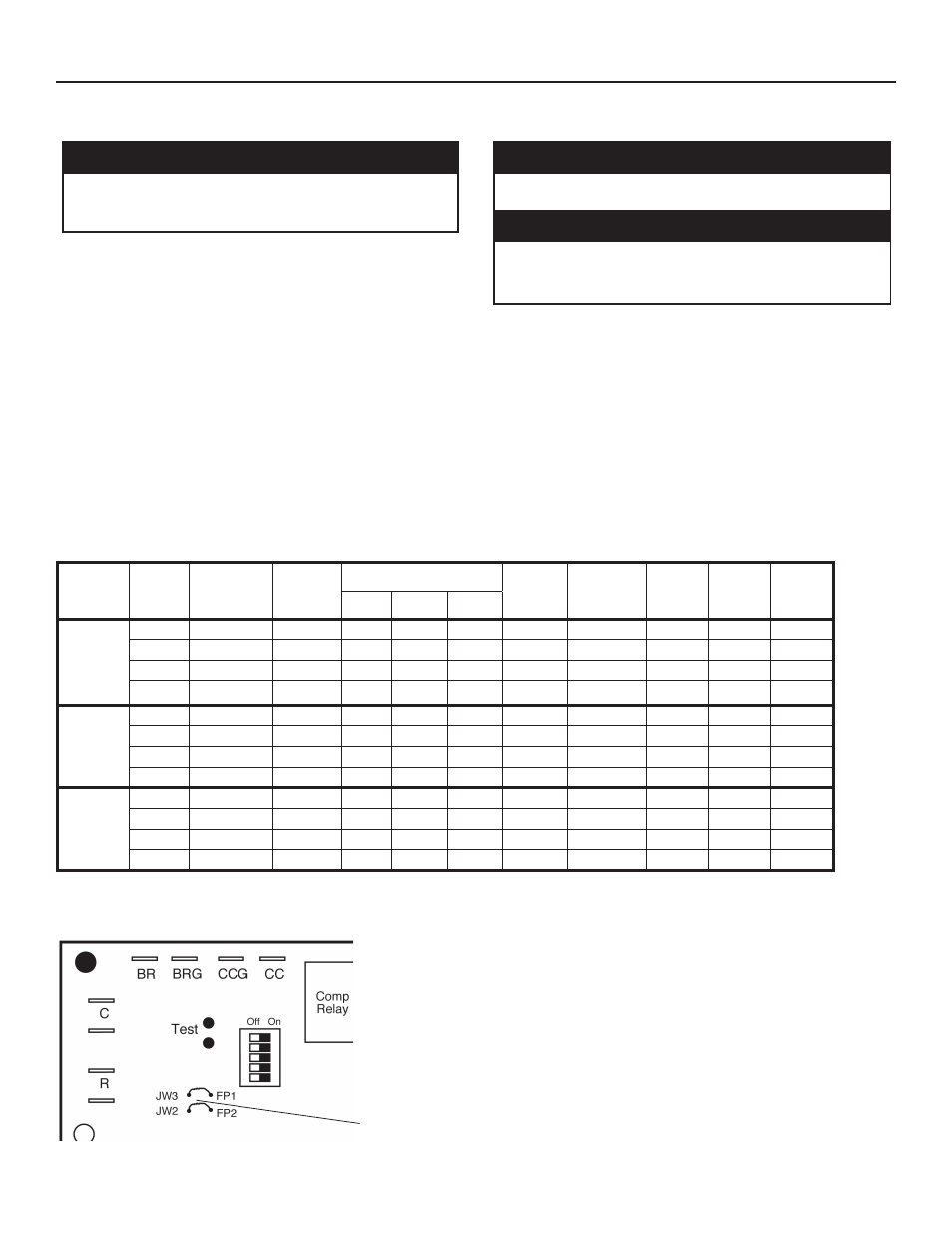

HWW Electrical Data

General Line Voltage Wiring

Be sure the available power is the same voltage and phase as

that shown on the unit serial plate. Line and low voltage wiring

must be done in accordance with local codes or the National

Electric Code, whichever is applicable.

HWW Power Connection

Line voltage connection is made by connecting the incoming

line voltage wires to L1, L2, and L3 on power distribution

block. Consult electrical data table for correct fuse size.

208 Volt Operation

All 208-230 Volt units are factory wired for 208 Volt. The

transformers may be switched to 230V operation as illustrated

on the wiring diagram by switching the Red (208V) and the

Orange (230V) at the contactor terminal L2.

All field installed wiring, including electrical ground, must

comply with the National Electrical Code as well as all

applicable local codes.

Refer to the unit wiring diagrams for fuse sizes and a

schematic of the field connections which must be made by the

installing (or electrical) contractor.

Consult the unit wiring diagram located on the inside of the

compressor access panel to ensure proper electrical hookup.

All final electrical connections must be made with a length of

flexible conduit to minimize vibration and sound transmission

to the building.

� CAUTION! �

Use only copper conductors for field installed electrical

wiring. Unit terminals are not designed to accept other

types of conductors.

� WARNING! �

To avoid possible injury or death due to electrical shock,

open the power supply disconnect switch and secure it in

an open position during installation.

� WARNING! �

Disconnect electrical power source to prevent injury or

death from electrical shock.

Thermostat Connections

The aquastat/thermostat should be wired directly to the CXM board

#1. Note: The HWW second stage is wired directly to the CXM #2.

Low Water Temperature Cutout - FP1

The CXM control allows the field selection of source fluid low tem-

perature cutout points. The factory setting of FP1 is set for water

(35°F [1.7°C]). In cold temperature applications jumper JW3 (FP1-

antifreeze 15°F [-9.4°C]) should be clipped as shown in Figure 4 to

change the setting to 10°F [-12.2°C], a more suitable temperature

when using antifreezes. Never clip JW3 prior to antifreeze being

added to the loop.

Figure 5: Changing FP1-Low Water Temperature Cutout Setpoint

CXM PCB

JW3-FP1

jumper

should be

clipped

when

antifreeze

is used.

Model

Voltage

Code

Voltage

Min/Max

Voltage

Compressor

HWG

Pump

FLA

EXT Loop

Pump

Fla

Total

Unit

FLA

Min

Circuit

Amps

Max

Fuse/

HACR

QTY

RLA

LRA

HWW036

1

208-230/60/1

187/254

1

16.7

79

0.4

4

16.7

20.8

35

3

208-230/60/3

187/254

1

10.4

73

-

-

10.4

13.1

20

4

460/60/3

414/506

1

5.8

38

-

-

5.8

7.2

15

5

575/60/3

518/633

1

3.8

36.5

-

-

3.8

4.7

15

HWW060

1

208-230/60/1

187/254

1

26.3

134

0.4

4

26.3

32.9

50

3

208-230/60/3

187/254

1

15.6

110

-

-

15.6

19.5

35

4

460/60/3

414/506

1

7.8

52

-

-

7.8

9.8

15

5

575/60/3

518/633

1

5.8

38.9

-

-

5.8

7.3

15

HWW120

1

208-230/60/1

187/254

2

26.3

134

0.4

4

52.6

59.2

80

3

208-230/60/3

187/254

2

15.8

110

-

-

31.2

35.1

50

4

460/60/3

414/506

2

7.8

52

-

-

15.6

17.6

25

5

575/60/3

518/633

2

5.8

38.9

-

-

11.6

13.1

15

HACR circuit breaker in USA only