Rivera Primo Brute II Classic & Classic User Manual

Page 2

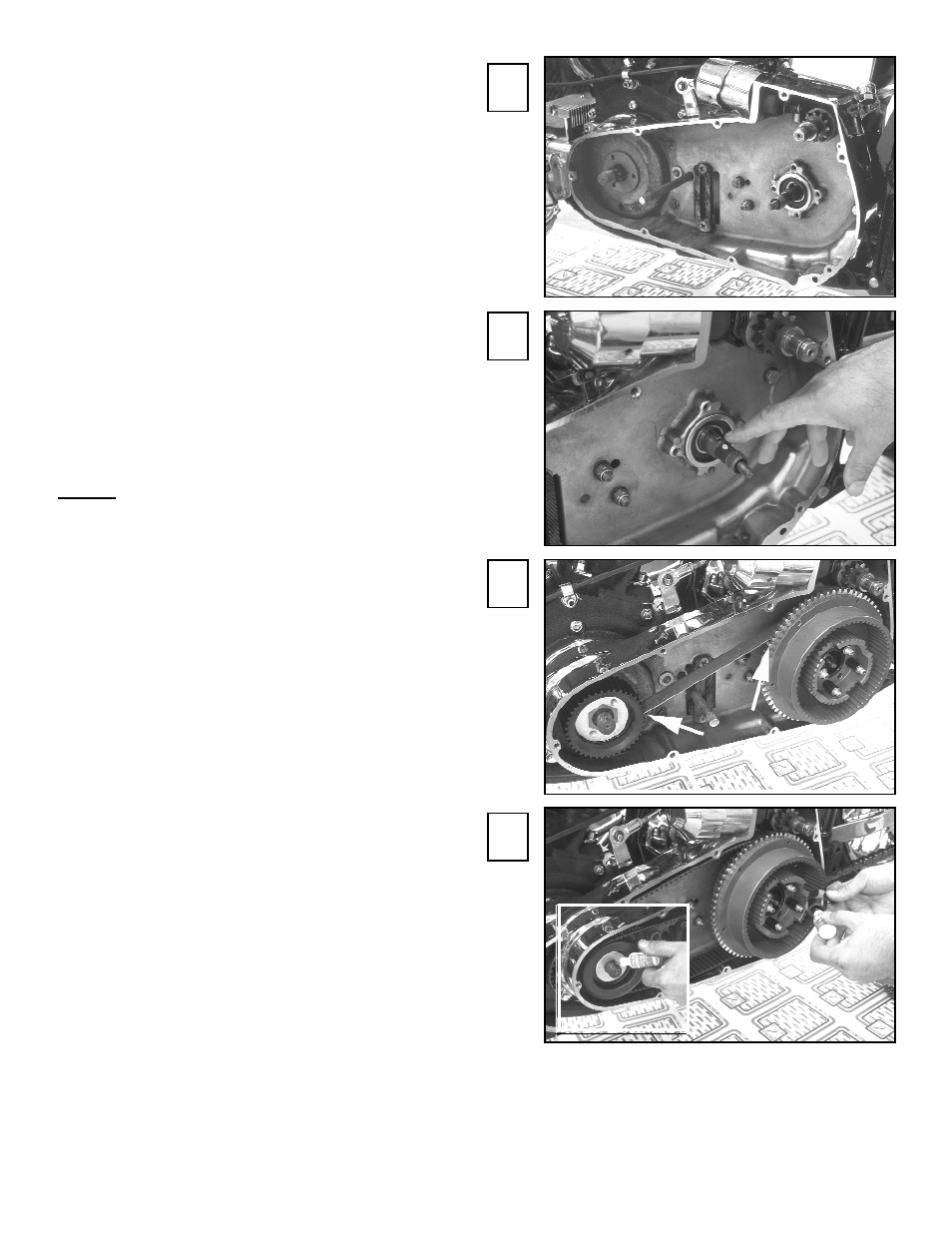

Remove all OEM drive train components and thoroughly clean the

inner primary. Inspect the inner primary for cracks or other damage.

The serrated plate must remain in place if you are installing the

11 mm Brute II Classic

TM

(as shown). It may be removed if you are

installing the 8mm Brute Classic

TM

.

Note: Make sure the inner primary bolts are safety-wired or use

Loctite. Studs should have nylock nuts!

Check the fit of the clutch hub on the mainshaft first, making sure it

fits properly & there are no burs, etc. Remove the clutch hub & then

install the KEY in the KEYWAY ensuring that it is correctly seated and

oriented so that the clutch hub will slide into place on the transmis-

sion main shaft. If you cannot seat the key correctly, check for burrs

on the key or keyway, deburr as needed and reinstall.

Caution: Keyway must remain stationary when basket is installed.

Install the clutch hub / rear basket assembly on the main shaft, and

the front pulley on the motor shaft. Hand tighten the nut on the main

shaft. Hold a straight edge firmly against the inner surface of the ring

gear as shown. The outer edge of the front pulley must line up with

the inner surface of the ring gear as shown before proceeding.

Shims can be inserted or removed behind the front pulley to achieve

correct pulley alignment.

Order part number PX-1, a package of 5 different shims. . .

(.020”, .030”, .050”, .075” and .100”)

After correct pulley alignment is established, install the belt on the

pulleys, slide the pulleys into place taking care that the KEY is cor-

rectly seated in the KEYWAY (rear pulley-hub assembly). Place

2 drops of thread lock (blue) on the threads of the clutch hub nut

prior to permanently installing the nut. TIGHTEN THE CLUTCH HUB

NUT TO 70-80 FOOT POUNDS using a high-quality torque wrench.

REPEAT THE PROCEDURE FOR THE MOTOR SHAFT NUT.

TIGHTEN TO 150-165 FOOT POUNDS using a quality torque

wrench or air impact driver.

1

2

3

4

2