100 hydraulic tubing notcher operations – Mittler Bros Machine & Tool 100-U User Manual

Page 8

- 8 -

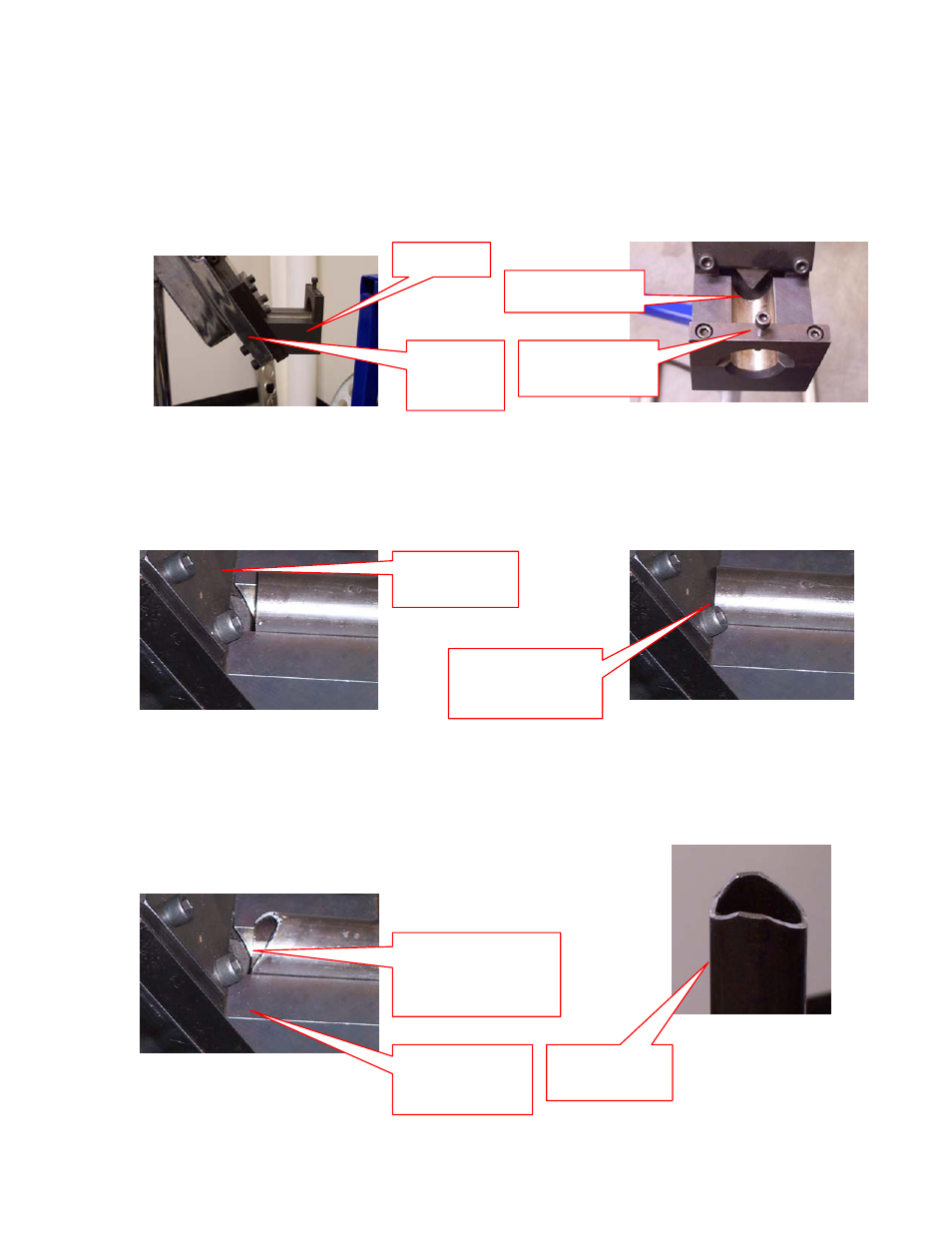

Flush against the

Punch Holder

Plate

#100 Hydraulic Tubing Notcher Operations

1. The #100 Hydraulic Tubing Notcher is designed to notch tubing by cutting one side of the notch at

a time. This is accomplished by having a pointed SLIDING PUNCH entering the end of the tube at

an angle to the DIE PLATE.

2. To make a 90° Notch, slide the tube into the die plate and up against the PUNCH HOLDER

PLATE. Tighten down the HOLD DOWN BOLT. Run the hydraulics until you hear the punch

complete the cut. Release the hydraulics, loosen the hold down bolt & rotate the tube 180° and

then repeat the process, be sure to retighten the hold down bolt.

3. To make an Angled Notch, follow step

2 above for the first half of

the notch. For the second half of the

notch, hold the tube back

from the PUNCH HOLDER PLATE. The

exact distance will be

determined by the angle required and the size of the tube. You

may need to make some sample notches to get the ideal distance

back that your angle and tube size requires.

Slide Tube Into

Punch less

than 1

st

. Cut.

Die Plate

Sliding Punch

Punch Holder

Plate

Resulting

Angled Notch

Angled

Frame

Assembly

Hold Down Bolt

& Clamp Assm.

This Distance

Varies depending

on the Angle

Required