Shaft and sleeve replacement guidelines, Bearing-frame inspection – Goulds Pumps LF 3196 i-FRAME - IOM User Manual

Page 85

Shaft and sleeve replacement guidelines

Two types of sleeves

The 3198 is offered with either a metallic sleeve that uses the standard 3196 shaft or a Teflon sleeve. The

Teflon sleeve requires a special shaft and a different inboard labyrinth oil seal.

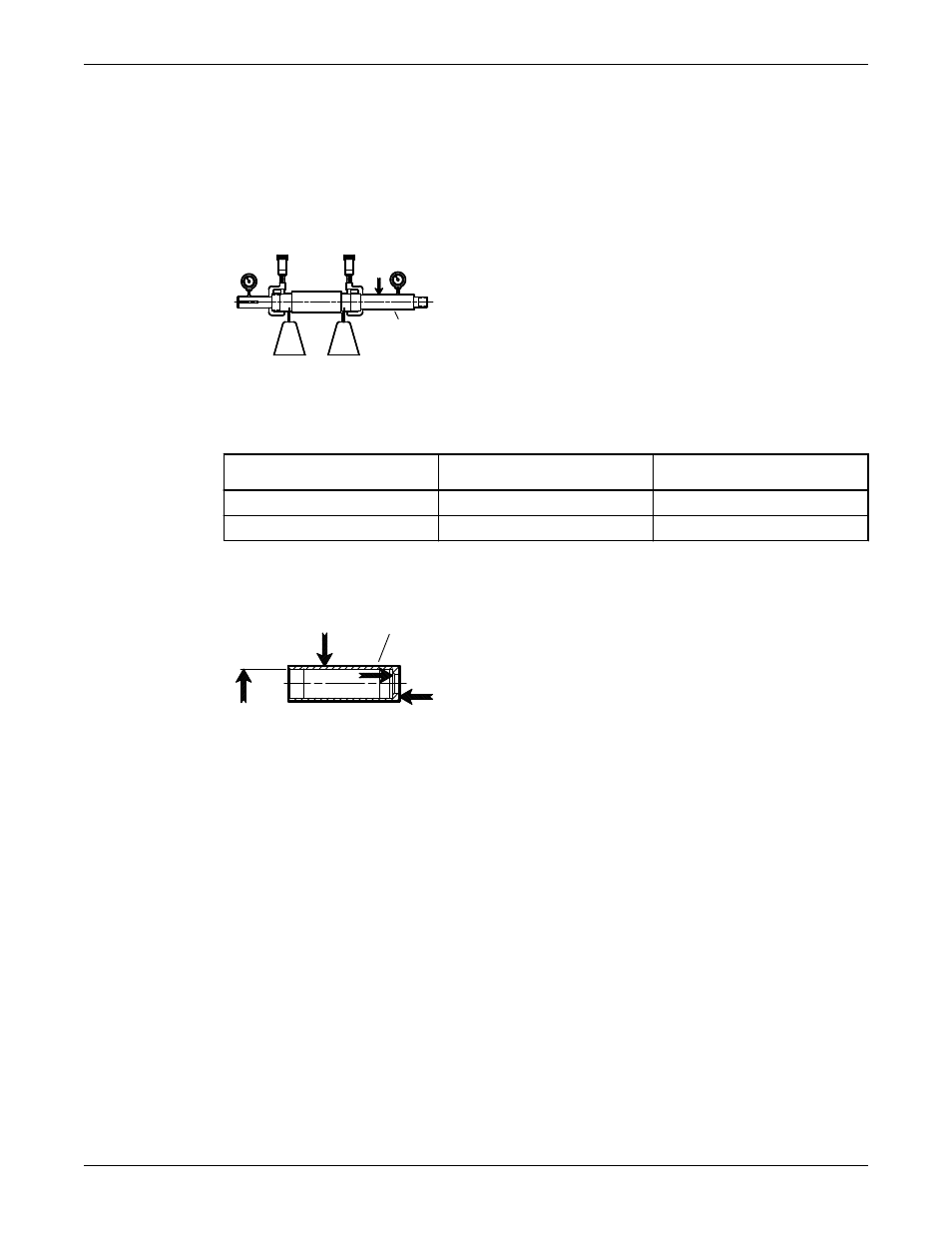

Shaft measurements check

Replace the shaft (122) if any measurements exceed acceptable values. See Bearing fits and tolerances.

122

Straightness check

Replace the shaft (122) if runout exceeds the values in this table:

Table 13: Shaft runout tolerances for sleeve fit and coupling fit

Sleeve fit in inches

(millimeters)

Coupling fit in inches

(millimeters)

With sleeve

0.001 (0.025)

0.001 (0.025)

Without sleeve

0.002 (0.051)

0.001 (0.025)

Shaft and sleeve check

126

• Check the shaft and sleeve (126) surface for grooves and pitting.

• Replace the shaft and sleeve if any grooves or pits are found.

Bearing-frame inspection

Checklist

Check the bearing frame for these conditions:

• Visually inspect the bearing frame and frame foot for cracks.

• Check the inside surfaces of the frame for rust, scale, or debris. Remove all loose and foreign material.

• Make sure that all lubrication passages are clear.

• If the frame has been exposed to pumped fluid, inspect the frame for corrosion or pitting.

• Inspect the inboard-bearing bores.

If any bores are outside the measurements in the Bearing fits and tolerances table, replace the bearing

frame.

Surface inspection locations

This figure shows the areas to inspect for wear on the bearing frame outside surface.

Maintenance

Model LF 3196 i-FRAME Installation, Operation, and Maintenance Manual

83