Goulds Pumps ChemBasePlu - IOM User Manual

Page 8

ChemBasePlus™ 02/15/02— 1/2002

Page

7 of 16

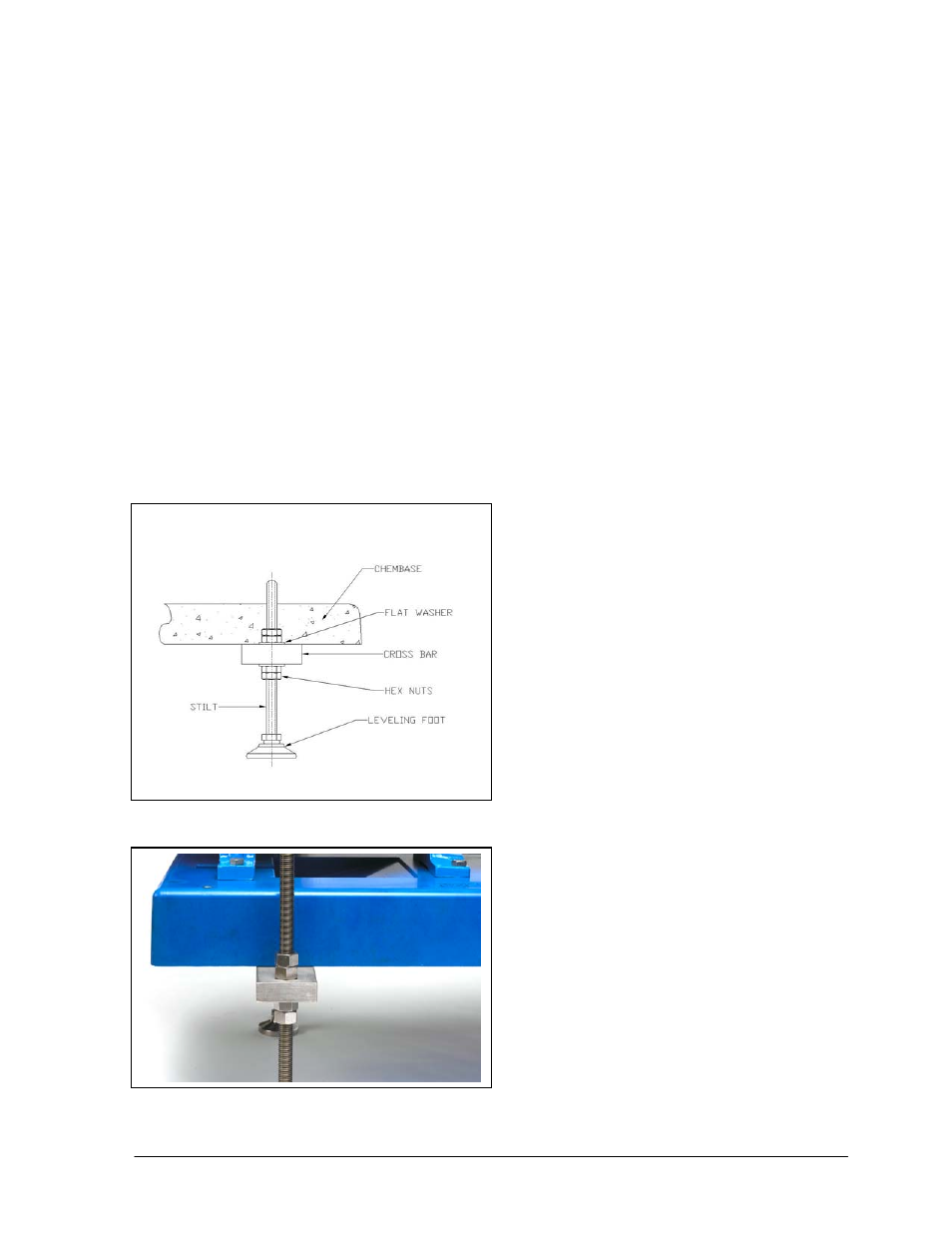

4.4 STILT MOUNTED BASEPLATES

As mentioned previously, the

ChemBasePlus™ is inherently rigid due to its

thickness of construction. The end result is a

baseplate that can be stilt mounted while not

sacrificing on reliability. The pump/motor

alignment techniques for Goulds’ Stilt Mounted

baseplates follow the same methodology of the

grouted in baseplates. The key difference

revolves around the way the baseplate is

leveled.

1) The stilt mounted baseplate is set on a

flat surface with no anchor bolts

needed.

2) The baseplate is leveled by using the

nut stilt adjuster kit. Refer to

Figures 8 and 9 for suggested

assembly instructions.

FIGURE 8

FIGURE 9

a) Elevate the baseplate assembly

above the floor to allow stilt

assembly.

b) Measure the approximate desired

height of the baseplate assembly

above the foundation.

c) Locate the bottom nuts above the

stilt threaded bolts to desired

height.

d) Insert the lock washer over the stilt

bolt.

e) Move the threaded stilt bolt up

through the holes in the bottom of

the baseplate and secure in place.

f) Attach the remaining lock washer

and nuts on to the threaded stilt

bolt. Fasten the nut on to the lock

washer.

g) Secure all four threaded stilts.

Now locate the baseplate

assembly over the flexible leveling

feet and tighten the feet to the

threaded stilts. Now lower the

entire assembly to the foundation.

h) Make final level and height

adjustments by simply loosening

the top nuts and turning the bottom

nuts to raise or lower the

baseplate assembly.

i)

Finally, first tighten the top and

bottom nuts located on the

respective lock washers and then

tighten the other nuts to insure the

baseplate is properly locked in

place.

At this point, follow the steps as listed above

(Steps 12, 13, and 14) for grouted baseplates.