Goulds Pumps ChemBasePlu - IOM User Manual

Page 16

ChemBasePlus™ — 1/2002

Page

15 of 16

3) Negative Reading - The coupling halves

are further apart on the right side than the

left. Correct by either sliding the shaft end

of the driver to the left or the other end to

the right.

Positive Reading - The coupling halves

are closer together on the right side than

the left. Correct by either sliding the shaft

end of the driver to the right or the other

end

to the left (Fig. IV-3).

4) Repeat steps 1 through 3 until indicator A

reads .002 in. (.05 mm) or less.

5) Re-check both horizontal and vertical

readings to ensure adjustment of one did

not disturb the other. Correct as

necessary.

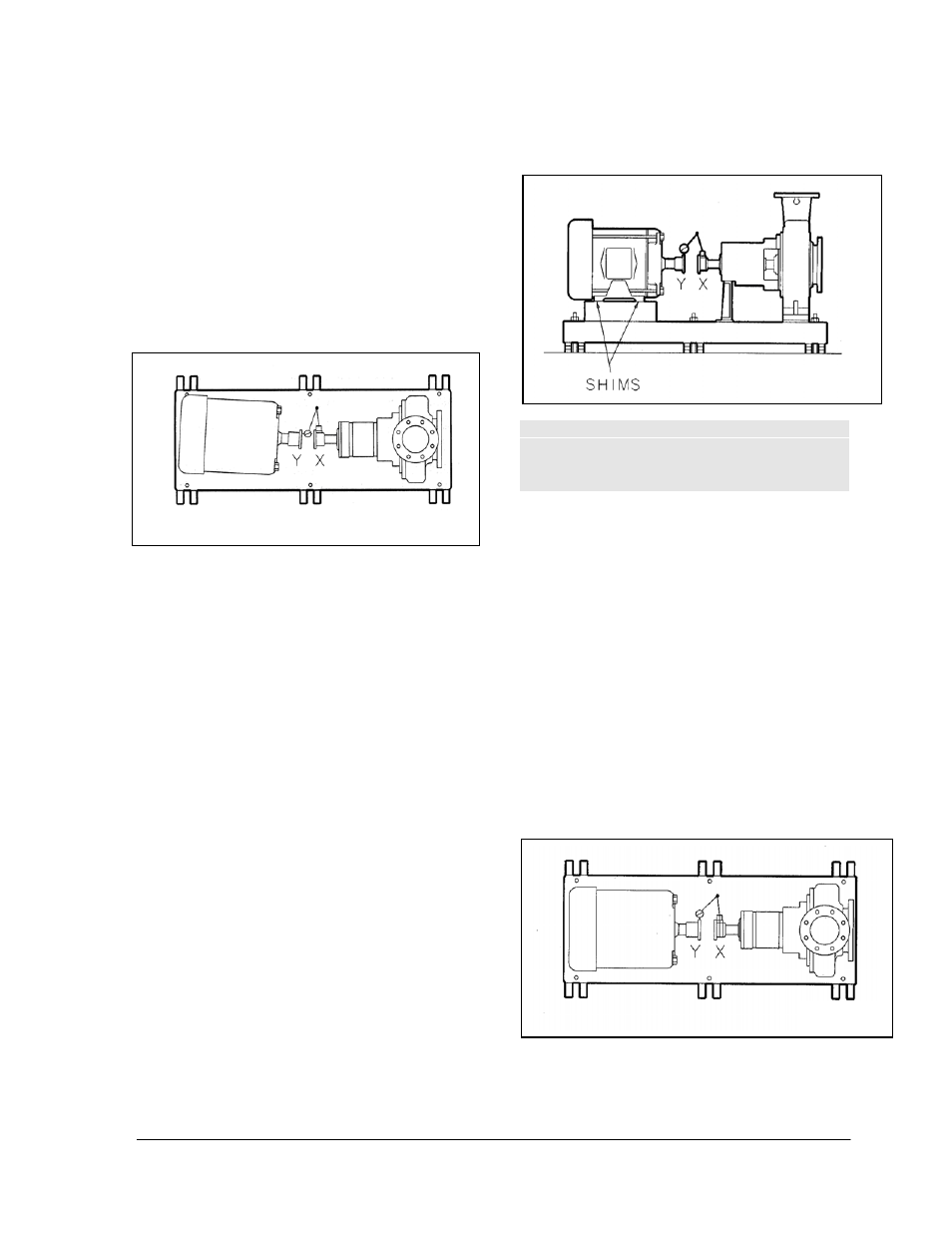

PARALLEL ALIGNMENT

A unit is in parallel alignment when indicator P

(parallel indicator) does not vary by more than

.002 in. (.05 mm) as measured at four points

90° apart at operating temperature. Note the

preliminary vertical cold setting criteria, Table

1.

Vertical Correction (Top-to-Bottom)

1. Zero indicator P at top dead center of

coupling (12 o’clock) half Y (Fig. III-1).

2. Rotate indicator to bottom dead center (6

o’clock). Observe needle and record

reading.

3.

Negative Reading - Coupling half X is

lower than coupling half Y. Correct by

removing shims of thickness equal to half

of the indicator reading under each driver

foot.

Positive Reading - Coupling half X is

higher than coupling half Y. Correct by

adding shims of thickness equal to half of

the indicator reading from each driver foot

(Fig. IV-4).

NOTE: Equal amounts of shims must be

added to or removed from each driver foot.

Otherwise the vertical angular alignment will be

affected.

4.

Repeat steps 1 through 3 until indicator P

reads within .002 in. (.05 mm) or less when

hot, or per Table 1 when cold.

Horizontal Correction (Side-to-Side)

1. Zero indicator P on the left side of coupling

half Y, 90° from top dead center

(9 o’clock).

2. Rotate indicators through top dead center

to the right side, 180° from the start

(3 o’clock). Observe needle and record

reading.

3.

Negative Reading - Coupling half Y is to

the left of coupling half X. Correct by

sliding driver evenly in the appropriate

direction (Fig. IV-5).

Positive Reading - Coupling half Y is to

the right of coupling half X. Correct by

sliding driver evenly in the appropriate

direction.

NOTE: Failure to slide motor evenly will affect

horizontal angular correction.

4.

Repeat steps 1 through 3 until indicator P

reads .002 in. (.05 mm) or less.

5.

Re-check both horizontal and vertical

readings to ensure adjustment of one did

not disturb the other. Correct as

necessary.

Fig. IV-4

Fig. IV-3

Fig. IV-5