APTech Series AK M60 User Manual

Page 7

AK M60 Manual

P/N 00-15000012 Rev 1

Page 7 of 13

4.3.

Connect Gas Lines to M60

Refer to Figure 3 for a schematic of the recommended installation that shows the relative location of the

AK M60 crossover manifold and other components. AP Tech recommends both a check valve and

manual valve are used to isolate each gas cylinder from the AK M60 crossover manifold. It is possible to

isolate the AK M60 manifold from each gas cylinder using only either a check valve or a manual valve.

The Source A high pressure inlet ports are labeled with “HP-A” marked into the body. Arrows are used

next to the HP-A to point toward the high pressure gauge port and the high pressure inlet port. The

Source B high pressure inlet ports are similarly labeled with “HP-B” and arrows.

The low pressure outlet ports are labeled with “LP” marked into the body near the port. Arrows are used

next to the LP to point toward the low pressure port (both the outlet pressure gauge port and outlet port).

Position a gas cylinder on each side of the AK M60 manifold. Secure cylinders in place using an

appropriate restraint system.

Equipment can be supplied with various types of fittings and connections. The standard connections are

1/4 inch female NPT. Inspect the system to determine if the connection is NPT, tube compression, or

other.

Install a check valve into port labeled “HP-A” on AK M60 manifold. Flow arrow on check valve should

be pointing into the AK M60 manifold inlet port. Install a manual shut off valve onto check valve.

Install a check valve into port labeled “HP-B” on AK M60 manifold. Flow arrow on check valve should

be pointing into the AK M60 manifold inlet port. Install a manual shut off valve onto check valve.

Connect a “pigtail” (bent piece of tubing with loops for flexibility and to reduce stress on connections) or

flexible braided hose from the outlet of the left cylinder valve to the manual valve on the AK M60

manifold regulator inlet port labeled “HP-A”.

Connect a “pigtail” (bent piece of tubing with loops for flexibility and to reduce stress on connections) or

flexible braided hose from the outlet of the right cylinder valve to the manual valve on the AK M60

manifold regulator inlet port labeled “HP-B”.

Install appropriate fitting into AK M60 manifold 1/4 inch NPT female outlet port. Install delivery line to

point of use using tubing or piping. A tee should be placed on the delivery line close to the AK M60

manifold for installation of a relief valve.

4.4.

Relief Valve Installation

Install a relief valve on one leg of tee installed as part of the delivery line. The relief valve should be set

above the AK M60 crossover regulator pressure settings. See Table 1 for recommended nominal relief

valve set pressures. If necessary due to gas properties, route the relief valve outlet line to an appropriate

scrubber or exhaust system. Otherwise, direct the relief valve outlet away from personnel.

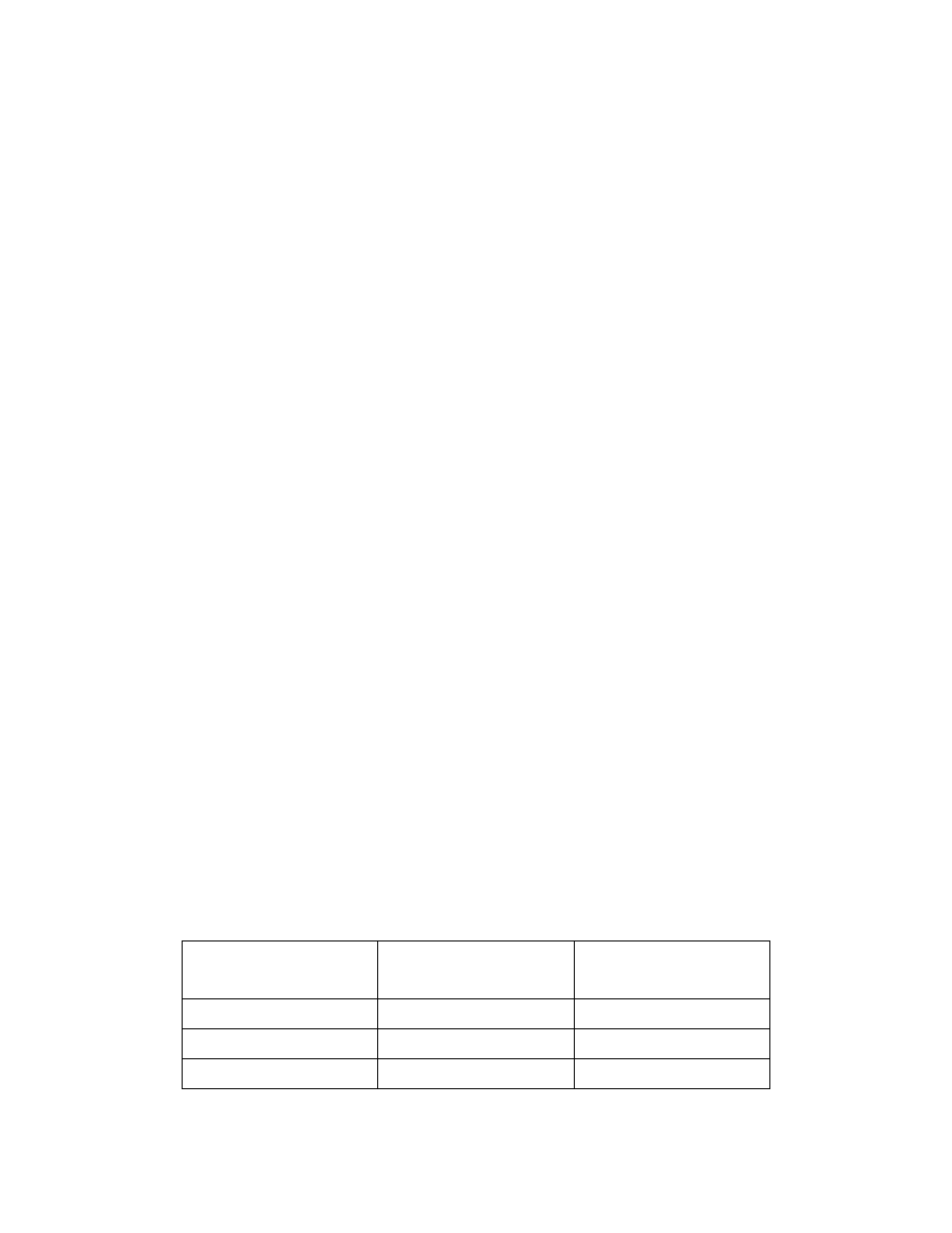

AK M60 Model

Nominal Crossover

Regulator Outlet Range

Relief Valve

Set Pressure

AK M6010

85-115 psig

150 psig

AK M6015

135-165 psig

200 psig

AK M6025

225-275 psig

325 psig

Table 1. Crossover Relief Valve Nominal Set Pressures