Barksdale Series 20313 User Manual

Page 2

Barksdale, Inc. 3211 Fruitland Avenue, Los Angeles CA 90058 (800)835-1060 www.barksdale.com Bulletin No. 272378-B, 4-3-14

2

1.0 GENERAL

To ensure proper and safe operation of a Barksdale Regulator, the entire manual must be read and understood

clearly. Please pay special attention to all safety information.

This sign is used in this instruction is in case of hazards which might results in injuries and damages.

2.0 INTENDED USE

Barksdale's pressure regulators are sensitive, pressure-control devices used to maintain a pre-determined

pressure in a hydraulic circuit. The regulated output pressure is controlled by adjusting the spring force by air or

hydraulic motor or manually to balance the hydraulic loading. Design features ensure excellent accuracy,

repeatability and high flow coefficients. This regulator works on Shear-Seal® technology which uses fluid

pressure to maintain a leak-free metal to metal seal.

3.0 PED COMPLIANCE

To ensure that products intended for Europe meet the requirements of PED, it is necessary to determine the

proper PED classification. In the PED, pressure equipment can be classified one of the following categories.

• SEP (Sound Engineering Practice)

• Category I, II, III, IV

3.1 SEP Products

This product falls under SEP category as per PED directive

97/23/EC.

The SEP classification applies to pressure equipment that is not subject to Category I, II, III, or IV conformity

assessment, but must be designed and manufactured with “sound engineering practice” as defined by the PED.

3.2 Product Classification

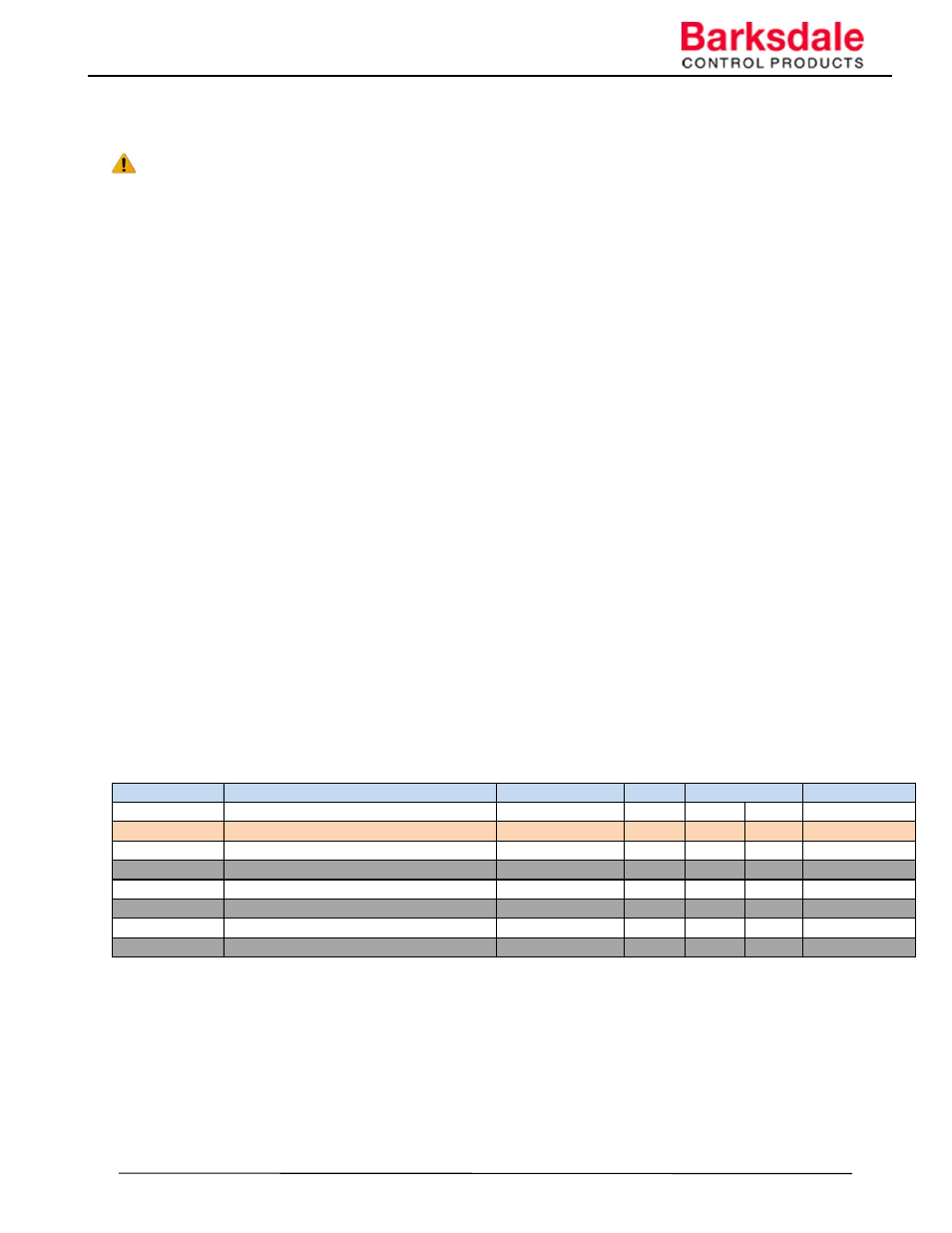

Use the Table 1 below to find the PED category of a specific product. Due to PED Classification limitations,

some products may not be available at full rated pressures. Be sure to check the PED Product Classification

table for any limitations.

Table 1. PED categorization

Refer product configurator for more options.

4.0 SAFETY INFORMATION

The recommendations below are general and it is the responsibility of the user to assure that installation and

maintenance are in accordance with local requirements, API and ASME practices. This regulator should be

installed by a trained service person. A media filter should be in the system to protect the regulator. It should not

be installed for safety purpose. To maximize life it is suggested to follow ISO fluid cleanliness code

ISO4406:1999 or thereafter. Neither Barksdale nor its agents assume any liability for regulator improperly used

in the application or improperly installed and maintained.

MODEL

DESCRIPTION

PORT SIZE (in)

DN (mm)

PED CATEGORY

VALVE #

Inlet / Outlet / Vent

Inlet

PSI

Bar

Annex II Category

20313

1/2" Heavy Duty Shear‐Seal Regulator

0.5 / 0.5 / 0.5

12.7

5000

345

SEP

20313S6WQ2

Manual operated ‐ High Sensitivity

0.5 / 0.5 / 0.5

12.7

5000

345

SEP

20313S6WQ2‐1

Manual operated ‐ Full Range

0.5 / 0.5 / 0.5

12.7

5000

345

SEP

F20313S6WQ2

Air motor operated ‐ High Sensitivity

0.5 / 0.5 / 0.5

12.7

5000

345

SEP

F20313S6WQ2‐1

Air motor operated ‐ Full Range

0.5 / 0.5 / 0.5

12.7

5000

345

SEP

GF20313S6WQ2

Hydraulic Motor Operated ‐ High Sensitivity

0.5 / 0.5 / 0.5

12.7

5000

345

SEP

GF20313S6WQ2‐1 Hydraulic Motor Operated ‐ Full Range

0.5 / 0.5 / 0.5

12.7

5000

345

SEP

SUPPLY PRESSURE