4" bore installation continued – ACE Controls 4" Bore Self-Compensating User Manual

Page 2

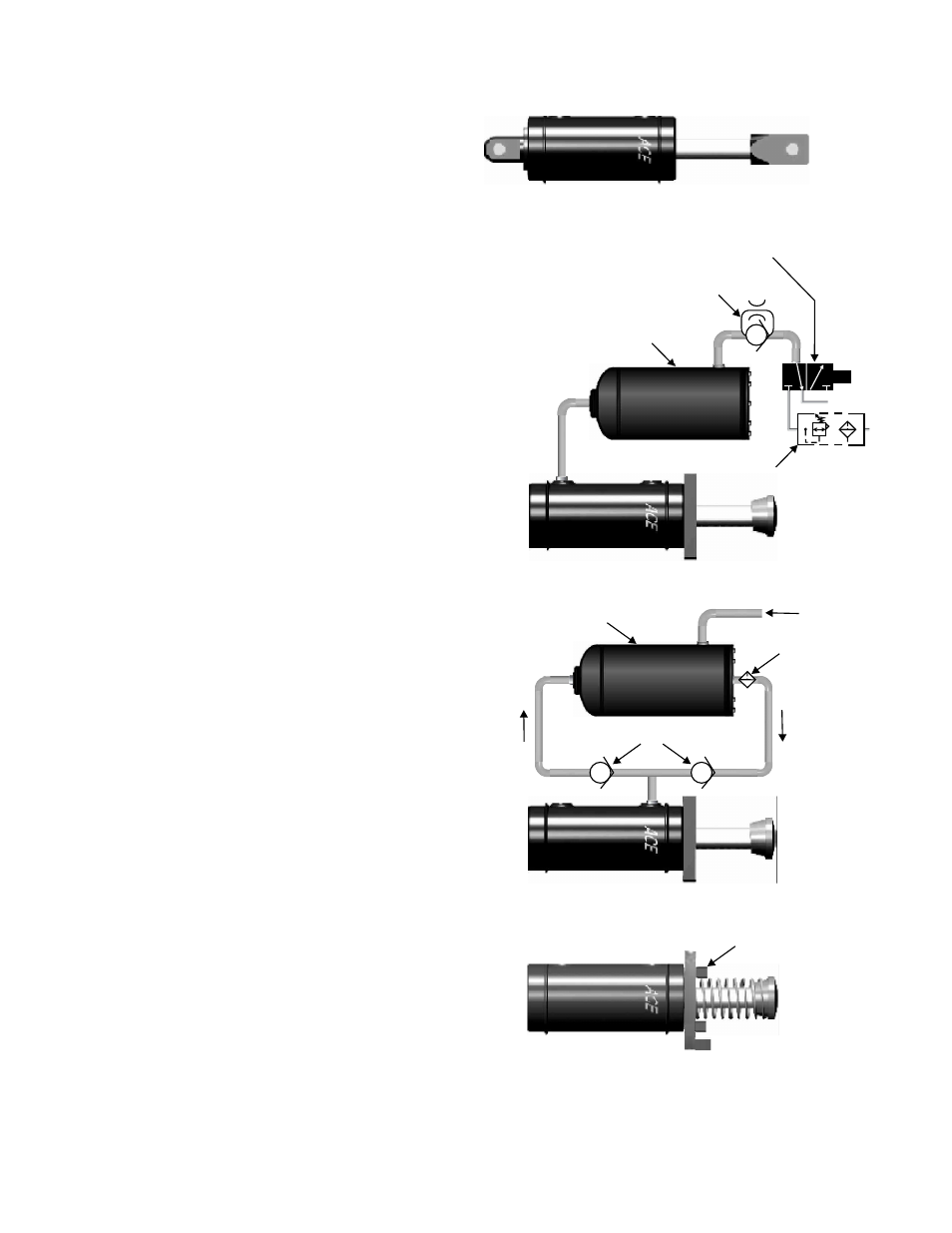

Figure 4

World leader in deceleration technology

ISO 9001:2000 Certified

ACE Controls Inc.

ACE Form24, 4” Bore Sel-Comp.

04/01/2004

CLEVIS MOUNTING INSTALLATION

Fasten the rear clevis and the rod clevis (Figure 4) to

the mating clevis members of the equipment. Make

sure the shock absorber is using the full stroke plus

.03 in (0.8 mm) and is not bottoming out. Be sure

that the equipment cannot pull the rod out any further

than the shock absorber stroke will allow.

AIR EXHAUST CIRCUIT FOR MODEL

CAA SHOCK ABSORBER

This type of installation (Figure 5) is necessary when

it is desired to have the rod remain in the shock

absorber after decelerating the load. Use special care

to avoid overfilling the air-oil tank. If not built in, a

special ACE check valve should be used to eliminate

“misting” of oil out of the air-oil tank.

RE-CIRCULATING COOLING CIRCUIT FOR MODELS

CAA & CSA SHOCK ABSORBERS

This type of installation (Figure 6) may be required when

ambient temperatures and/or cycle rates cause a self

0

contained shock to heat beyond 200 F. Use high pressure

(1,000 psi) check valves with a low cracking pressure

(5 psi). If a filter is to be used in this circuit, a 30 to 40

micron filter element with a 5 psi by-pass is recommended.

Consult factory for assistance.

PRIMARY MOUNTING INSTALLATIONS

Install the ACE self-compensating shock on a surface of

sufficient strength. Align the shock absorber rod end

button with the load striking surface and the bleed screws

and/or ports pointing up if mounted horizontally. Tighten

the (6) 5/8-18 UNF screws securely (Figure 7).

Figure 5

Optional Filter

(6) 5/8-18 UNF

Air Supply

Air-Oil Tank

Figure 6

Figure 7

Exhaust

Supply

Special ACE

Check Valve

Air-Oil Tank

Filter/Regulator

3-Normally

Closed Valve

Sol

High Pressure Check Valve