ACE Controls CB Series User Manual

Cb filling instructions

1. This CB shock absorber contains pressurized gas to return the piston rod.

2. In order to ship by regular air freight and minimize freight costs, regulations

require the gas pressure to be reduced from 80 psi (5.5 bar) to 40 psi (3 bar).

3. On receiving this unit, it is recommended that the pressure be returned to

80 psi (5.5 bar) to generate the catalog ratings for the piston rod return force

and guarantee that the piston rod will fully extend.

4. Nitrogen is recommended for corrosion protection, air can be used but

could cause internal corrosion and will void the warranty.

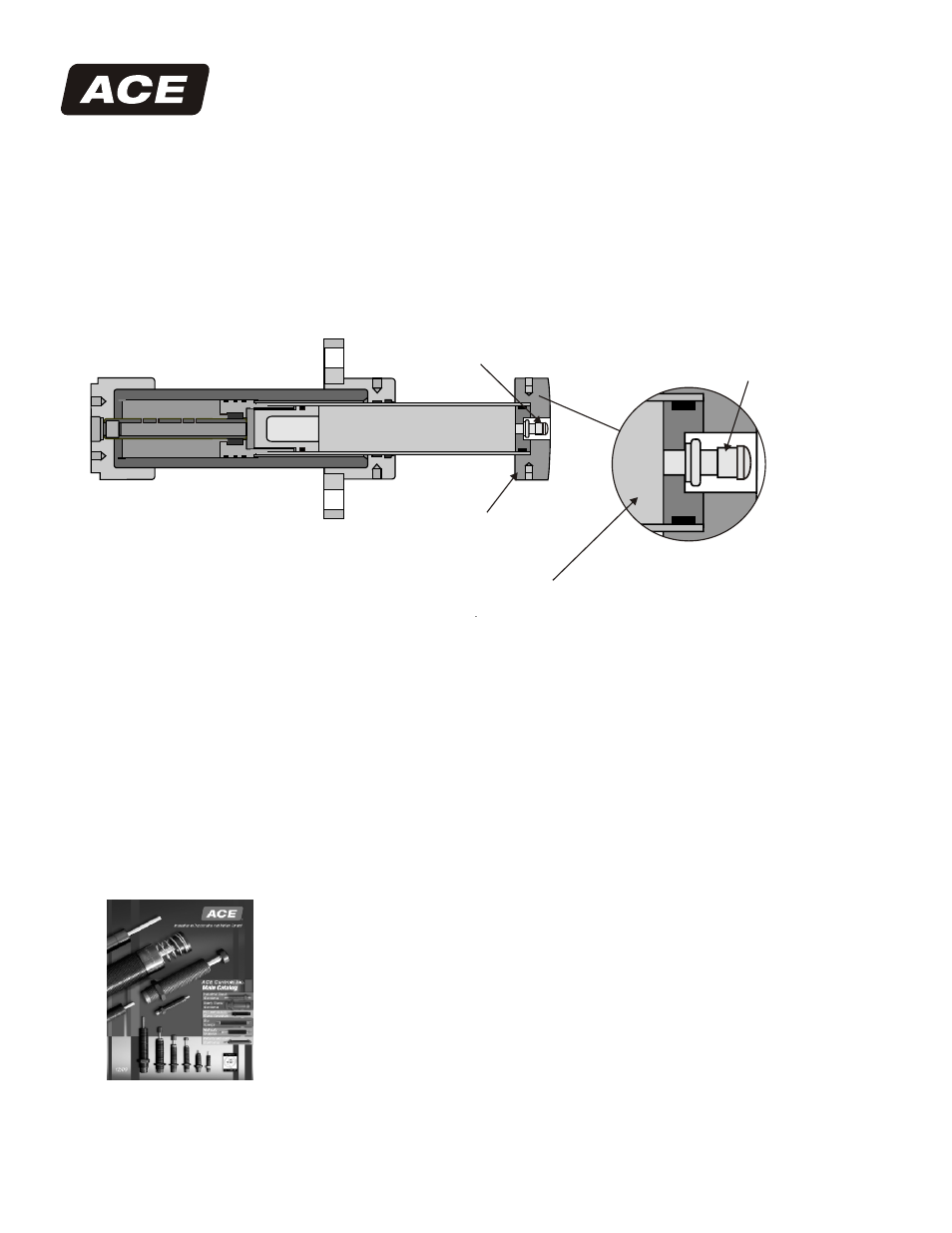

Valve Assembly

Button

a. Remove red cover to

expose Schrader valve

b. 40 psi (3 bar) for shipping

80 psi (5.5 bar) for catalog rating

ACE Products and services:

CB Filling Instructions

23435 Industrial Park Drive

Farmington Hills, Michigan 48335

tel: 248.476.0213

fax: 248.476.2470

www.acecontrols.com

Innovation in Deceleration and Motion Control

ISO 9001

ACE Controls Inc.

Decelerate loads, prevent impact damage, dampen noise and increase cycle speeds

with ACE industrial shock absorbers. Shock absorbers providing true linear

deceleration solve shock-related problems more efficiently and effectively than any

other device, at a fraction of the cost. ACE provides the most comprehensive design

and applications support in the industry.

DESIGN - Unique simulation software offers a superior method of evaluating both

standard and custom design options, greatly reducing prototypes and design time.

CUSTOMER TOOLS - With ACE’s sizing software and CAD file library, you can select

and integrate shock absorbers directly into your design process.

APPLICATIONS ASSISTANCE - If you need more information, ACE offices and

distributors are located in over 100 cities worldwide to help provide applications

solutions

ACE Form 22, CB Filling Instructions

08/04/2010