Air-oil tanks cont'd, Notice, Side port torque notice – ACE Controls ACE MLS 64 Adjustable Series User Manual

Page 2: The shock absorber to heat up beyond 150 f, Figure 3, Ace controls inc

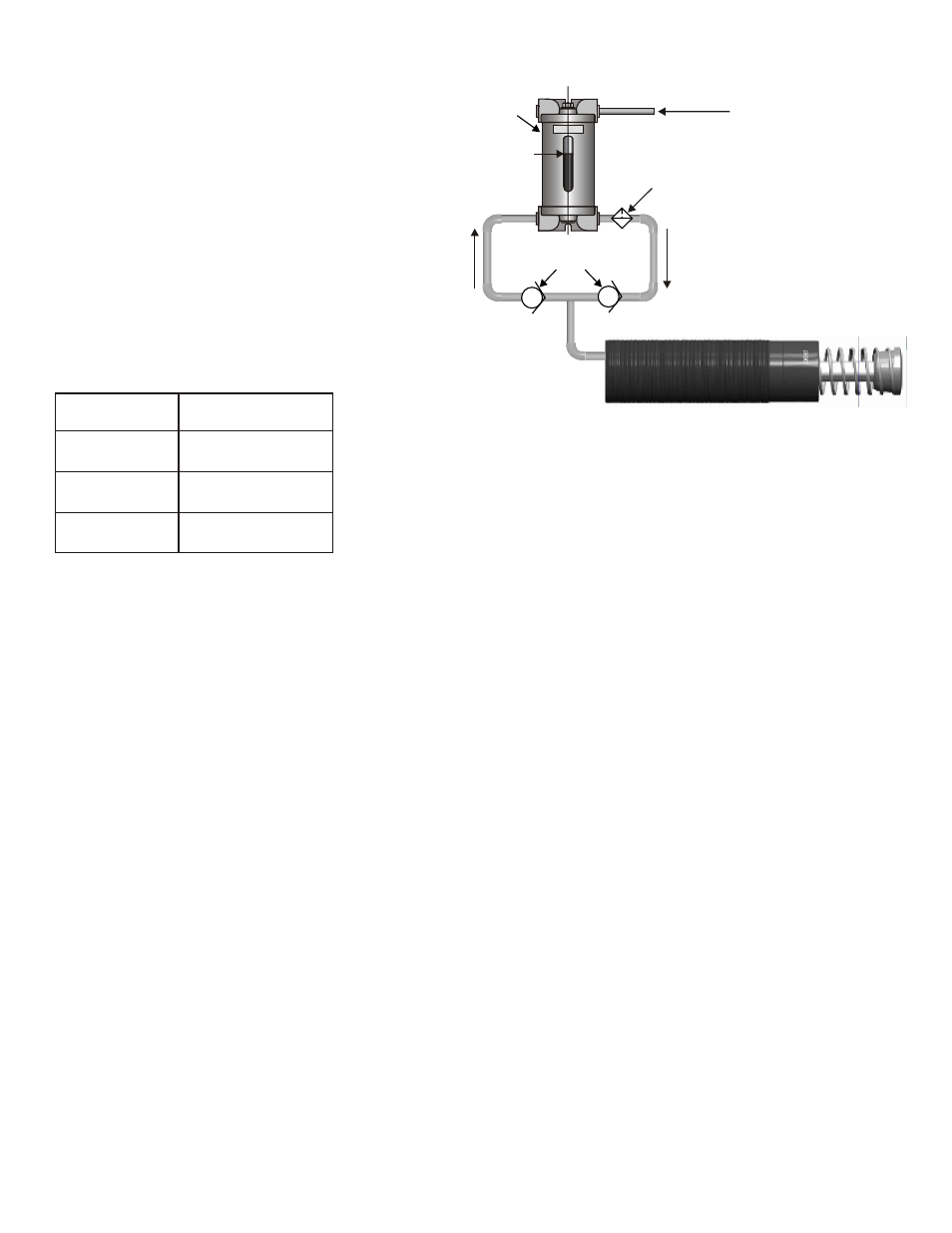

RE-CIRCULATING COOLING CIRCUIT FOR

MODELS MCA, MCS, MAA, MAS, MLA and

MLS (Figure 3)

This type of installation may be required when

ambient temperatures and/or cycle rates cause

0

the shock absorber to heat up beyond 150 F

0

(65 C).

Use high pressure 1,000 psi (69 bar) check valves

with a low cracking pressure of 5 psi (0.34 bar).

If a filter is to be used in this circuit, a 30 to 40

micron filter element with a 5 psi (0.34 bar) by-pass

is recommended. Consult factory for assistance.

LOCK NUT TORQUE SPECIFICATIONS

Refer to the chart below when installing shock

absorber lock nut.

Model

MC, MA, ML

33, 36 Series

MC, MA, ML

45 Series

MC, MA, ML

64 Series

Torque/Lock Nut

54 - 59 ft-lbs

(74 - 81 Nm)

167 - 183 ft-lbs

(225 - 250 Nm)

560 - 610 ft-lbs

(755 - 830 Nm)

M

A

4

5

5

0

2

C

O

N

T

R

O

L

S

I

N

C

.

above this line

Do not fill

WARNING

Do not use near open flame

contents may be flammable

Air Supply

Optional Filter

Figure 3

For Magnum Group 33 & 36 models

the torque specification for the male

connector, shipped loose, is 6-10 in-lbs

(0.68 - 1.13 Nm)

Notice

For Magnum Group 33 & 36 Series

1/8” NPT, Torque 25-30 in-lbs (2.82-3.38 Nm)

For Magnum Group 45 & 64 Series

1/4” NPT, Torque 30-35 in-lbs (3.38-3.95)

Side Port Torque Notice

APPLYING APPROPRIATE TORQUE

WITHOUT CALIBRATED TOOLING

The following procedure may be utilized if

calibrated tooling is not available to torque

lock nut.

Note: it is assumed that all necessary

installation instructions have been followed

prior to this procedure.

1. After positioning the shock properly in relation

to the accessory (i.e. flange, collar, etc.) or

mounting surface, with the proper adhesive (if

applicable), finger tighten the lock nut against

the accessory or mounting surface until it can no

longer be turned.

2. Using appropriate equipment, tighten the

lock nut until it rotates 1/8 to 1/4 of a full rotation

(45 to 90 degrees) from the finger tight position.

ACE has determined that a lock nut secured in

this manner meets the torque specifications

listed in the chart above.

Air-Oil Tank

High Pressure

Check Valve

World leader in deceleration technology

ISO 9001:2000 Certified

ACE Controls Inc.

ACE Form 17, Air-Oil Tank, Magnum

04/01/2004

- ACE MLS 45 Adjustable Series ACE MLS 36 Adjustable Series ACE MLS 33 Adjustable Series ACE MLA Adjustable Series ACE MAS Adjustable Series ACE MAA Adjustable Series ACE MCS 64 Self-Compensating Series ACE MCS 45 Self-Compensating Series ACE MCS 36 Self-Compensating Series ACE MCS 33 Self-Compensating Series ACE MCA Self-Compensating Series