Quick Cable 800 Amp Booster Clamps Cable Assembly and Safety User Manual

Page 2

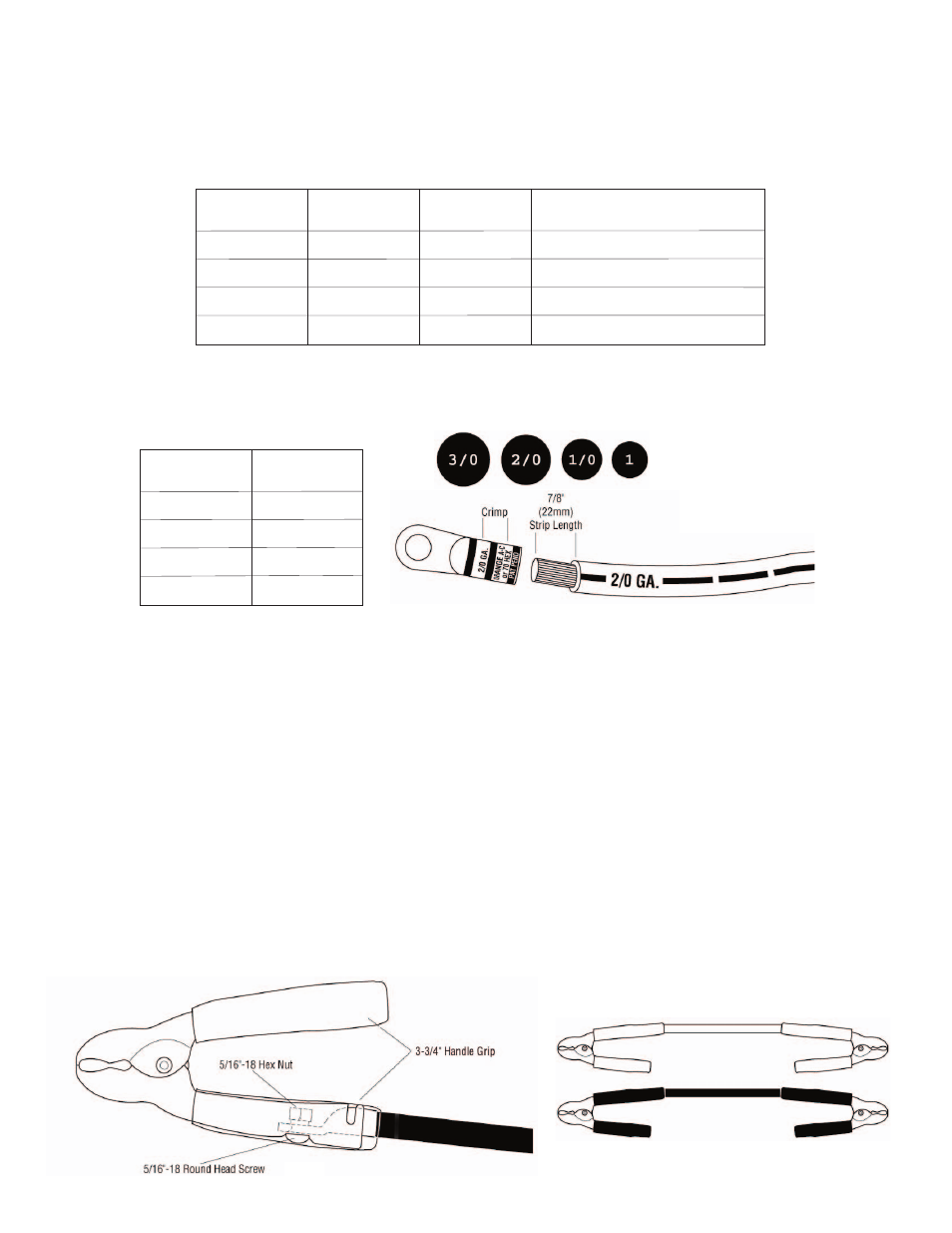

6. Heavy Wall Copper Lugs. Based on cable selected, use the appropriate heavy wall copper lugs below One lug is

required for one booster clamp. Four lugs are required for the typical set of booster cables. (The part numbers below

are for a box with five lugs.)

5. Guideline for Cable Gauge. For the proper gauge booster cable for your vehicle, please check your owner’s manual.

If this information is not available, use the following as a guideline. Important: the gauge size of your booster cables

should be larger than the largest and longest cable in your vehicle.

Cable Carrying Capacities

25’ (7.6M) Booster Cables

For Intermittent Duty Only (Not Continuous Duty)

The size bullets (left) will help

you determine the gauge (size)

of an unmarked cable.

Measure the bare conductor

only, not the insulation. Actual

diameters vary depending on the

specific stranding of the wire.

Fig. 1

Copper Cable

Gauge

1/0 Gauge

Up to 400 Amps

500 Amps

600 Amps

700 Amps

300 Amps

325 Amps

375 Amps

425 Amps

Full-size Car or Van

Light Truck, Light Construction, Small Tractor

Tractor, Truck, Bus, Construction

HD Tractor, Off Highway

2/0 Gauge

3/0 Gauge

Made of

Battery Cable

Typical Vehicle

1 Gauge

Made of

Welding Cable

Part Number

4810-005F

1 Gauge

1/0 Gauge

2/0 Gauge

3/0 Gauge

4820-005F

4830-005F

4801-005F

Fits Cable Gauge

Fig. 2

7. Slide the handle grip onto and away from the end. Strip 7/8” to 1” (22 - 25 mm) of insulation from end of cable.

Insert bared wires into barrel of lug. Crimp lug on to cable. Use two crimps on barrel for best connection. See

Figure 1.

8. One handle of the booster clamp is formed so that the heavy wall lugs will nest inside. Bolt the lug into place

according to Figure 2.

9. Slide the 3-3/4" (95mm) handle grip down over the handle and lug, according to Figure 2.

The handle grip tube will seal the cable, reducing corrosion, and it will also act as a strain relief for the cable, extend-

ing the life of your booster cable.

10. Push the other handle grip onto the other handle. Make certain the grips are the same color on both handles. See

Figure 2.

11. For a typical set of booster cables, install a second clamp on the other end of the cable. Make certain the same color

handle grip is used for both clamps on the same length of cable. Use black grips for the negative booster cable. Use

red grips for the positive cable. See Figure 3.

Note: For longer booster cables, increase the gauge of the cable.

Fig. 3