Calibration/maintenance accessories, Maintenance, Water inside the meter – Myron L EP-10 User Manual

Page 3: Standard solutions

standard solutions: a Standard Solution has a

known conductivity and ppm. Your meter was calibrated at

the factory using niST Standard Solutions. You can keep

your meter accurate by using the same niST Standard

Solutions. To pick the right Myron L Company Standard

Solution for your meter see aCCESSoRiES.

How often you calibrate your meter depends on how

much you use it. For once a day use, recalibrate it every

three months.

checking calibration

1. Turn the Range Switch to the x1000 range.

2. Test a sample of appropriate Standard Solution.

caution: Throw the Standard Solution away as you use

it. Don’t put the used samples back in the bottle.

3. if the meter does not indicate the same value as is on

the Standard Solution bottle’s label, first clean the cell.

For directions on how to do this see CELL CuP. Rinse

the cell thoroughly and test the Standard Solution again.

if the meter still does not indicate the correct value,

recalibrate it as described below.

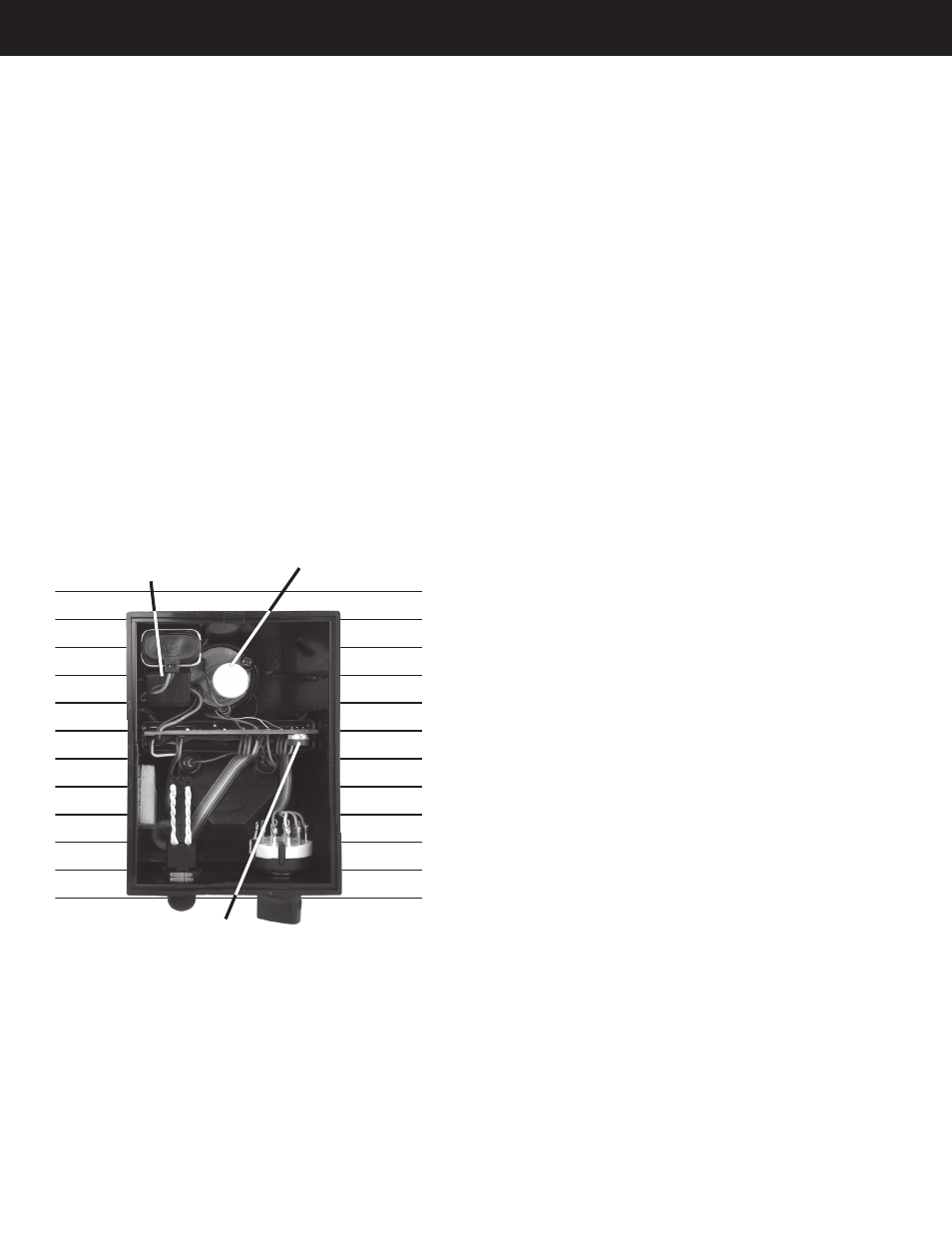

to recalibrate the meter

1. Remove the bottom cover using fingernails or a small

screwdriver to loosen the front or rear edge. identify the

Calibration Control (see photo below) so you can find it

by touch while calibrating.

2. Test another sample of the Standard Solution (be

careful to not splash solution inside the meter).

3. adjust the Calibration Control until the meter indicates

the value that is on the Standard Solution label.

maintenance

battery check

Models EP and EP-10 have a battery indicator glow light

visible through the small hole on the lower right-hand

corner of the meter face plate. if this light fails to glow

when the black button is pressed, replace the battery.

battery replacement

To replace the battery detach the battery connector.

Pull on the plastic strap to remove the battery. Replace

with fresh zinc carbon or alkaline 9 volt battery. Reinsert

the plastic strap to secure battery.

cell cup

Self-conditioning of the built-in electrodes occurs each

time the button is pressed with a sample in the cell cup.

This ensures consistent results each time. With some

samples a small downward swing of the pointer is a result

of this conditioning action. This action is powerful and

removes normal films of oil and dirt. However, if very dirty

samples — particularly scaling types — are allowed to dry

in the cell cup, a film will build up. This film reduces

accuracy. When there are visible films of oil, dirt or scale

in the cell cup or on the electrodes, scrub them lightly with

a small brush and household cleanser. Rinse out the

cleanser and the meter is ready for accurate

measurements.

water inside the meter

Your Myron L EP meter is a rugged instrument and will

withstand water exposure around its cell, meter

movement, and switches. However, care should be taken

to keep water from leaking in around the bottom cover. it

is not sealed (to prevent condensation from forming).

if water is relatively clean (i.e., tap water or better), and

there are only a few drops inside the meter, dry it as

described below. Large amounts of water, or corrosive or

very dirty solutions will almost certainly damage the meter

movement or electronics. Such meters should be returned

to the Myron L Company for repair.

To dry your meter:

1. Shake excess water out of the inside of the meter.

2. Dab the exposed surfaces dry with an absorbent cloth

or tissue. avoid pushing any water into the Calibration

Control or switches.

3. air dry the meter in a warm area with the bottom cover

off. allow several hours for thorough drying.

if the water entered through a leak in the case or cell, or

if the instrument shows erratic readings or other unusual

behavior, return it to the Myron L Company for servicing.

warranty/service

Myron L EP and EP10 Meters have a limited two year warranty. if

your instrument fails to operate properly, check the battery and

calibration. if it still fails to function properly, return it prepaid to the

Myron L Company.

Faulty instruments may be returned to us without prior permission.

meters within two year warranty period:

Failures due to materials or workmanship will be repaired or

replaced (our option) without charge if returned freight prepaid. if

failure is deemed by the factory to have been caused by abuse or

tampering, the following procedure will apply.

instruments/controls out of warranty:

Diagnosis will be made and repairs completed providing the repair

charges are $90.00 or less.

note: actual repair charges may be less than this amount.

We will diagnose (but not repair) a returned meter and fax an

estimate of charges if anY of the following apply:

1. Repair charges will be more than $90.00.

2. You specifically request an estimate of required repairs and

charges.

3. The cost of required repairs exceeds one-half the list price of a new

instrument.

4. The instrument is over ten years old. Because of component

changes and improvements, such instruments can no longer be

repaired.

note: unrepaired meters are discarded unless you want them

returned to you. if so, there is currently a $35.00 charge per

unrepaired instrument to cover diagnosis and handling.

This warranty is limited to the repair or replacement of the Myron L

EP or EP10 Meter only. The Myron L Company assumes no other

responsibility or liability.

standard solutions

Your EP Meter has been factory calibrated with the

appropriate niST traceable Standard Solutions. all Myron L

Company Conductivity Standard Solutions are traceable to

the national institute of Standards and Technology and are

within 1.0% of Potassium Chloride reference solutions.

The concentrations of the reference solutions are

calculated from data in the international Critical Tables,

vol. 6.

Battery Strap

Calibration Control

Lower Electrode

(inside cell)

calibration/maintenance

accessories