Installation – Dow THERMAX™ Exposed Basement Applications User Manual

Page 2

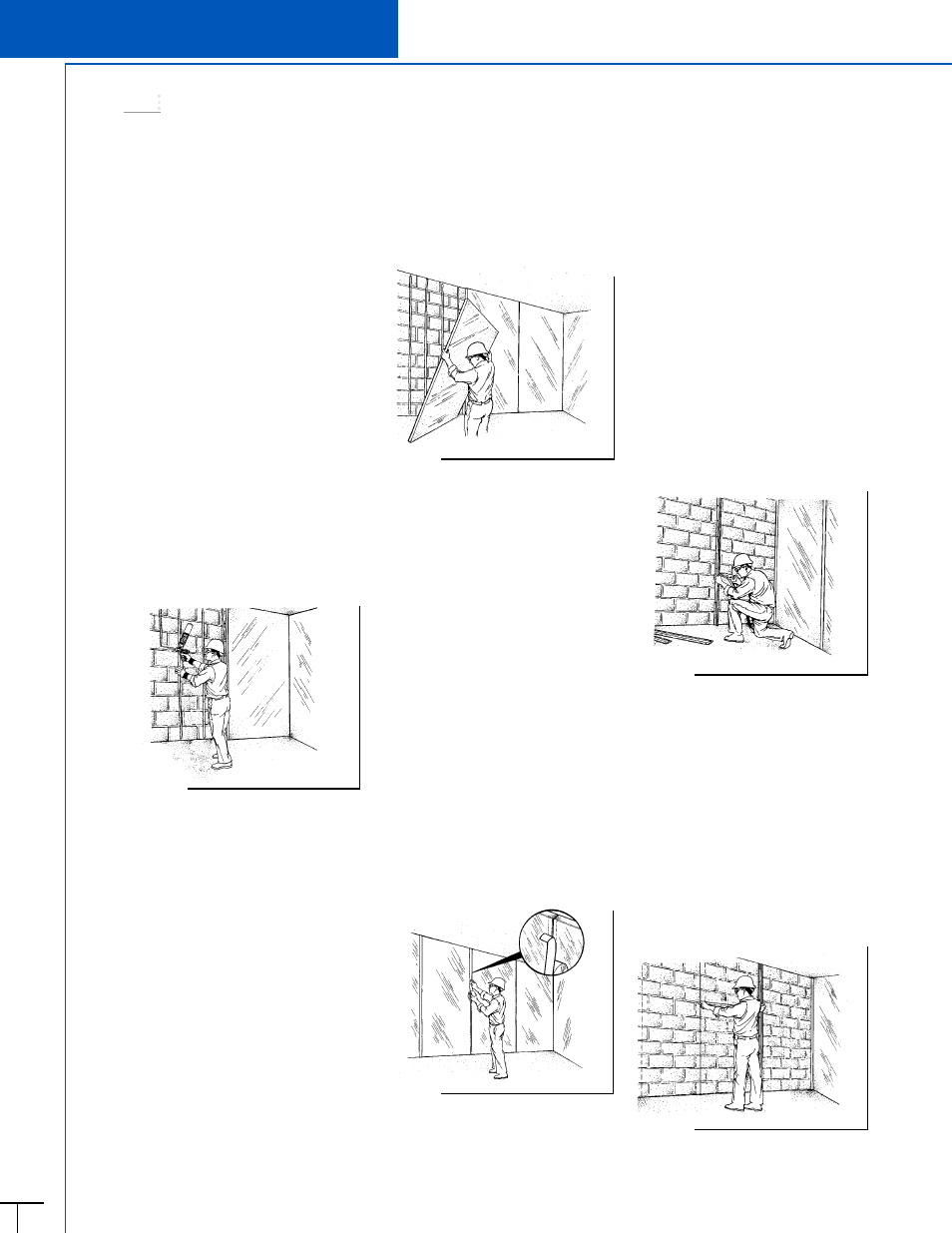

Installation

THERMAX

™

insulations may be

attached directly to the basement

wall with construction-grade

adhesive or with the PVC inter-

lock joint closure system. Both

installation methods offer a

quick and easy alternative to

using studs, batt insulation and

drywall.

OPTION 1: ADHERE DIRECTLY

TO WALL

1. Provide proper ventilation

and wear gloves and eye

protection.

2. Apply heavy beads (min.

bead size 3/8") of ENERBOND

™

MH or SF Polyurethane

Adhesive or appropriate

construction-grade adhesive

to the wall (Figure 2). Note:

Follow adhesive manufacturer

recommendations for

application pressure and cure

times for proper adhesion to

masonry walls.

2

I N S T A L L A T I O N I N F O R M A T I O N

3. Press insulation board

against the wall and butt

board edges tightly together

(Figure 3). Apply pressure to

board until the adhesive is

set. (Optional: Attach

mechanical fasteners to the

top and bottom of the board

to hold it in place until the

adhesive has set.)

4. For additional insulation

value and protection against

air infiltration, apply a small

bead of GREAT STUFF

™

Pro

Gaps & Cracks along board

seams. Take care that foam

does not get on insulation

facer during application.

Allow foam to fully cure,

then trim excess with a

serrated knife.

5. Cover seams between insula-

tion boards with aluminum

or white foil tape (Figure 4).

Before applying tape, wipe

the application area with a

damp cloth to remove foam

dust. Allow surface to air dry.

Use a squeegee or soft paint

roller to press the tape firmly

to the joint. Cut tape with a

knife or scissors. Do not tear

tape.

Figure 2

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

OPTION 2: PVC INTERLOCK

JOINT CLOSURE

For additional moisture control

and a more finished appearance

when insulating with THERMAX

™

White Finish insulation, use

the PVC interlock joint closure

system. The PVC interlock

joint closure system is com-

posed of a 2" wide PVC base

strip that is attached to the

wall at vertical joint locations

and a top “T” section that

snaps into the base, holding

the insulation boards to the

wall. The top “T” sections are

available in sizes to accommo-

date board thicknesses of 1",

1.5" and 2". Select the correct

top “T” section size for your

application. Both the PVC base

strip and top “T” sections are

sold in 10' lengths.

1. Measure and mark vertical

lines for the placement of

the PVC base strips. Space

the PVC base strips for the

correct width of the insula-

tion board (Figure 5). Allow

1/8" between the insulation

boards to accommodate the

width of the PVC base strip.

2. Fasten PVC base strip to con-

crete or masonry wall every

12" with a pneumatic nailer

or equivalent (Figure 6).

Figure 5

Figure 6

Figure 3

Figure 4