Dow THERMAX™ OR STYROFOAM™ User Manual

Page 3

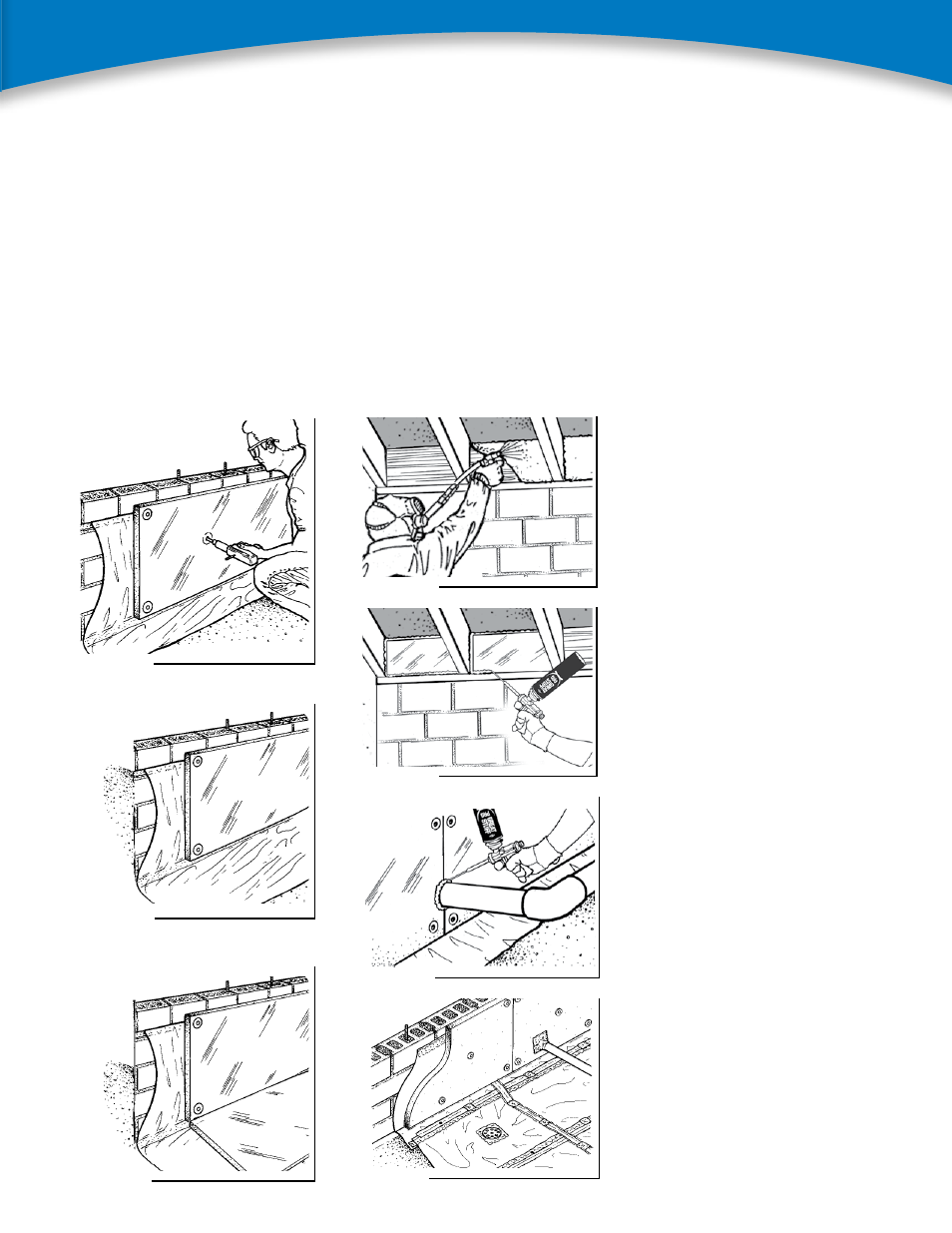

b. option 2: Use styrofoam™

brand rigid insulation

boards up to 2 inches in

thickness, cut to fit between

the floor joists, and seal

the edges of the foam with

Great stUff pro™ Gaps &

cracks. (see figure 5b.)

c. option 3: Use thermaX™

rigid insulation boards up to

4 inches in thickness, cut to fit

between the floor joists, and

seal the edges of the foam

with Great stUff pro Gaps

& cracks. (see figure 5b.)

3

Figure 5a

Figure 4a

Figure 4b

Figure 4c

Figure 6

Figure 7

Figure 5b

distance between the exterior grade

level and the crawl space floor is less

than 24 inches, the board on the wall

should extend to the crawl space floor

and then horizontally on the floor so

the total board length below exterior

grade (both vertically and horizontally)

equals at least 24 inches. (see

figure 4c.)

3. insulate the rim joist and sill plate.

there are three options for this step:

a. option 1: Use froth-paK™

foam insulation kits up to

2 inches in thickness. (see

figure 5a.)

4. seal all penetrations through

the crawl space wall with spray

urethane foam such as Great

stUff pro Gaps & cracks. (see

figure 6.) Joints between boards of

insulation may also be taped with

weathermate™ construction

tape, if desired.

5. install a temporary “construction”

poly liner as soon as the house is

“dried in” (i.e., tar paper is on the

roof). cover the floor area with poly,

but leave seams unsealed. this will

temporarily prevent moisture from

the soil from evaporating into the

crawl space.

6. Before installing the permanent poly

ground cover, temporary installation

of a small dehumidifier will help dry

out the moisture that already exists

in the crawl space. set the drain

tube to discharge outside of the

crawl space.

7. when the house is near

completion, remove the temporary

“construction” poly and discard.

8. roll out and install a permanent

type i Vapor retarder such as a

6-mil poly liner. the vapor retarder

sheets should overlap each other

by at least 6 inches. carefully seal

the seams at the wall poly liner with

duct tape and mastic. also seal

all joints and penetrations in the

field. (see figure 7.) secure each

joint with duct tape, then brush on

a layer of mastic. mastic should

extend at least 1 inch beyond the

tape on each side.

9. secure vapor retarder to the ground

with a 6-inch galvanized spike

through 1-inch diameter nailing tins.

for reinforcement and a tight seal,

apply duct tape and mastic over

spikes and tins.

the steps outlined here are intended to

make the crawl space clean, dry, well-

insulated, airtight and vapor tight. there

are other important components in a

closed crawl space system. consult irc

section 408 or www.crawlspaces.org for

other components such as ventilation

options.