Applic ation – Dow GREAT STUFF PRO™ User Manual

Page 3

Applic ation

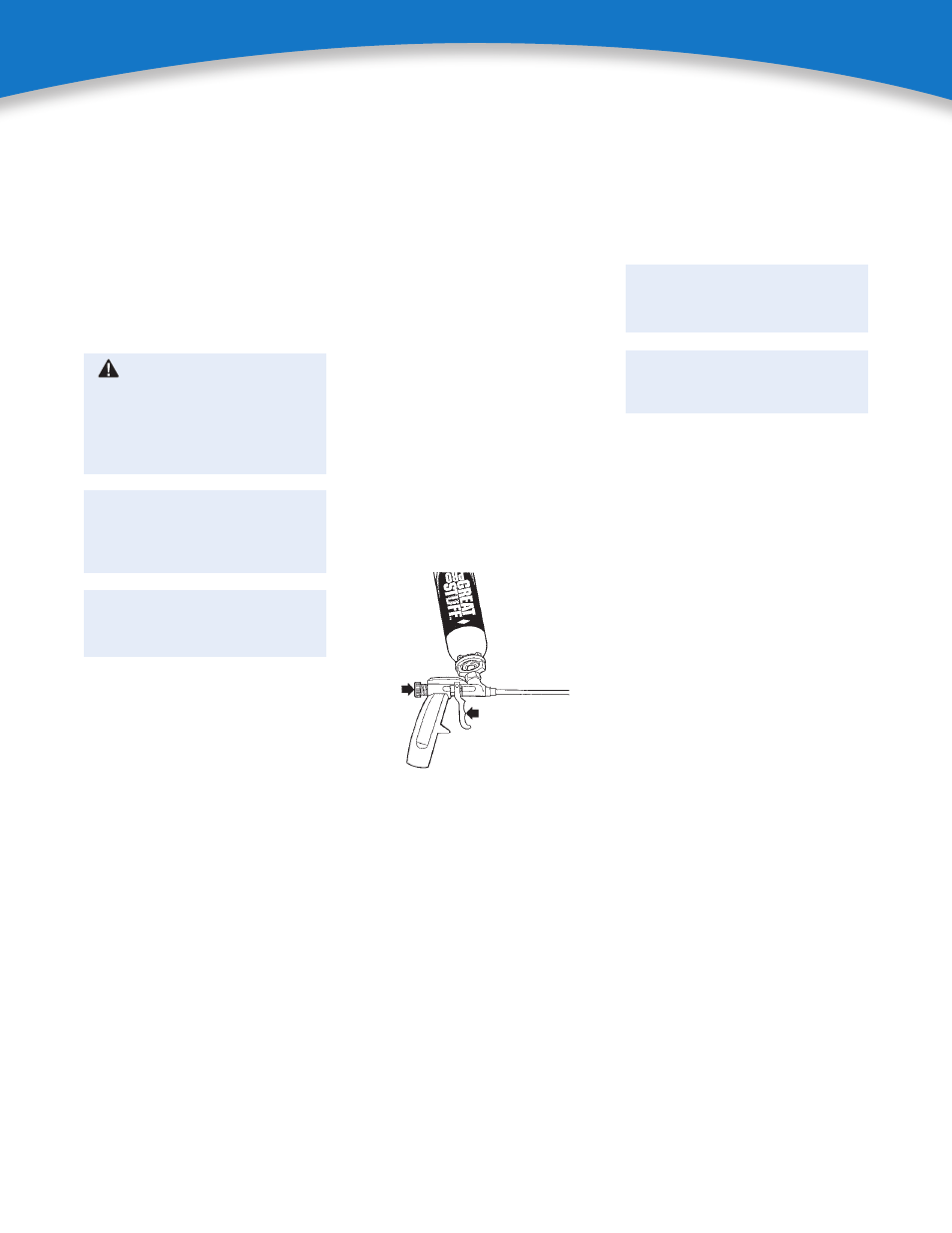

Gun-applied version:

1. Adjust flow control screw on

back of gun to an open position.

Immediately press trigger to fill

gun with foam while dispensing

into an appropriate waste

receptacle.

2. keeping can inverted, insert

applicator nozzle into the

penetration to be filled and begin

dispensing foam slowly. Fill gap

less than 50 percent full to allow

for proper expansion.

3. The foam dispensing gun is

recommended to control size of

the foam bead (from 1/8" to 3" [3

mm to 75 mm]). This is achieved

by squeezing the trigger on

the foam dispensing gun or by

adjusting the flow control knob on

the back of the gun to set how far

the trigger can be pulled (Figure 5).

4. If the gap is overfilled, stuff

excess cured foam into the gap

with a blunt tool or trim away

with a sharp knife. Foam will be

tack-free in less than 20 minutes

and can be trimmed in 1/2 hour.

It is fully cured 1 hour after

application.**

5. Clean foam dispensing gun

periodically by rubbing the end

on soft wood to free it from foam.

Do not use a sharp object to

clean foam dispensing gun. Use

a solvent cleaner such as GREAT

STUFF PRO™ Gun Cleaner

between extended periods of

non-use.

6. To store partially used can,

tighten flow control screw closed

and store can upright with gun

attached. Use can within 30 days

of initial use.

7. To reuse, shake can vigorously

for 1 minute before dispensing

and follow dispensing instructions

stated above.

Straw-applied version:

1. Attach the nozzle by twisting it

clockwise into the valve. Press

the button until the appropriate

size of foam bead is achieved. Fill

gap less than 1/3 full to allow for

proper expansion.

2. If the gap is overfilled, stuff

excess cured foam into the gap

with a blunt tool or trim away

with a sharp knife. Foam will be

tack-free in less than 20 minutes

and can be trimmed in 1/2 hour.

It is fully cured 1 hour after

application.**

3. Clean straw periodically by

rubbing the end on soft wood to

free it from foam.

4. When finished, bend the straw

back onto the plug on top of

the trigger assembly. The plug

prevents moisture from entering

and curing inside the straw or

valve.

5. To use after storage, gently rotate

or twist the straw to break the

adhesive bond of the foam. Pull

the straw off of the plug and

dispense.

Figure 5

CAUTION:

Do not inject the foam sealant

into blind cavities, such as

window mullions. The foam

must be exposed to atmospheric

moisture to thoroughly cure.

TIP: Using grease or petroleum

jelly in the adapter of the gun

may reduce possibility of foam

gluing the can on the gun.

TIP: Always close the flow

control knob when the gun is

not in use.

TIP: Treat your gun like a tool.

The better you take care of it,

the longer it will last.

TIP: Apply foam in a continuous

bead, with no voids or breaks, to

achieve an effective seal.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

**Dependent upon temperature, relative humidity and size of foam bead