Dow FROTH-PAK User Manual

Page 2

Form No. 179-05325X-0611P&M

178-00298X-0611P&M

McKAY209620

gENERAL APPLICATIONS

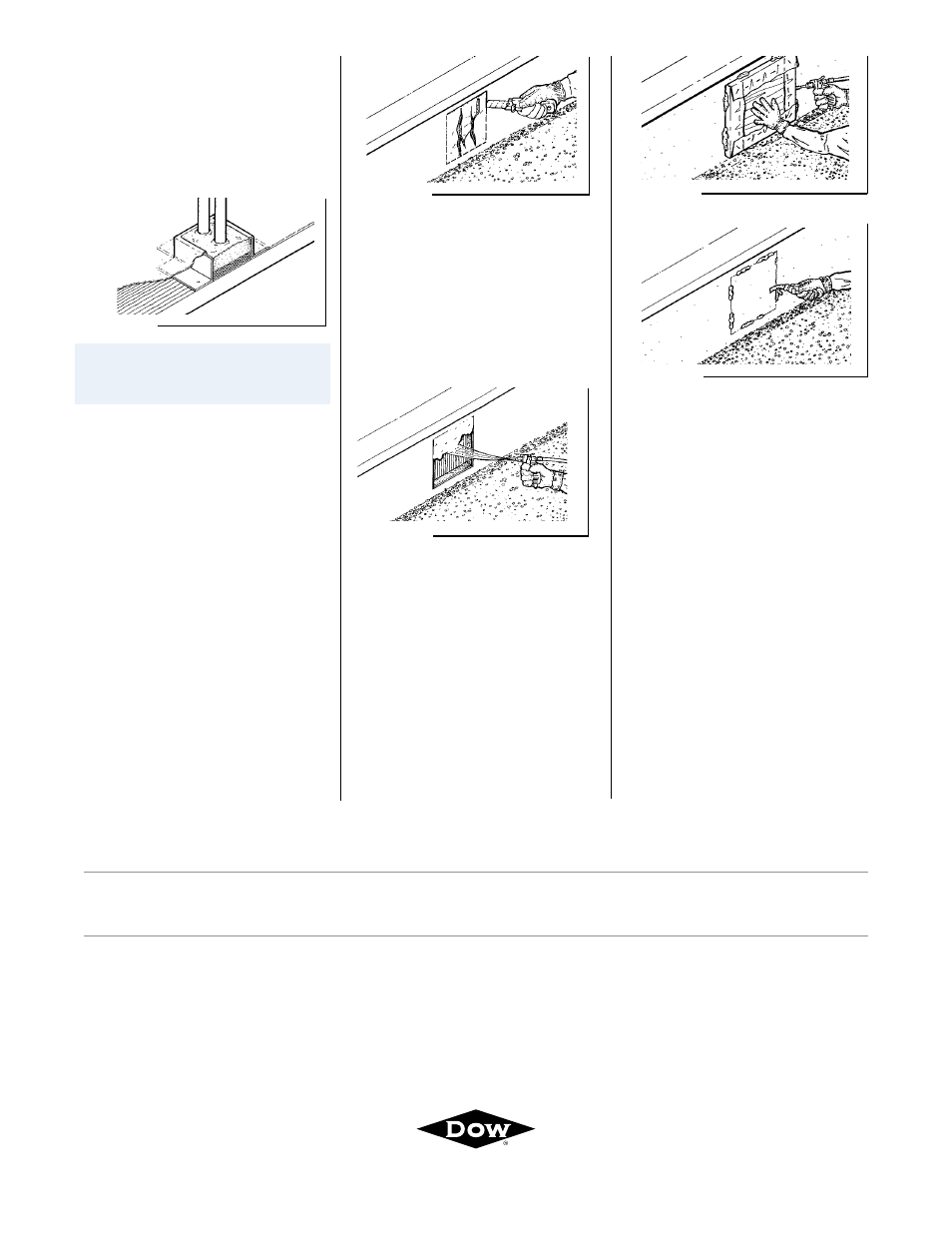

Fill small pitch pockets:

1. Depending on the depth of the

pocket, use two or more coats or

passes of the foam to obtain the

desired thickness (Figure 2). Apply

the foam in layers of 2" (5 cm) or

less in any single pass.

Note: If the foaming area to be filled is

wide, start by spraying from the edge

and build toward the center.

2. In approximately 5 minutes, the foam

should be no higher than the top of

the pocket.

Repair parapet/roof:

1. If the area to be repaired has been

previously painted, scrape away

all loose or poorly adhered paint.

Conduct an adhesion test if any

previously painted surfaces are

involved in the repair.

2. If the area is wet, let the surface

dry completely. Any additional

moisture may cause premature

curing and limit work time of the

FROTH-PAK

™

Foam Sealant.

3. Check the underlying substrate for

soundness and repair, if applicable.

4. Cut the damaged or blistered area

at an inward, tapered, 45° angle

(Figure 3). Cut back any defective

and moist foam until solid, dry

foam is exposed. Where possible,

remove at least 6" (15 cm) beyond

the area to be repaired.

5. Place a piece of plywood wrapped

in polyethylene next to the area to

be filled.

6. Depending on the depth of the

repair area, use two or more coats/

passes of FROTH-PAK

™

Foam

Sealant to obtain a thickness that

is approximately 2" (5 cm) from the

top of the area. Apply the foam in

layers of 2" or less in any single

pass (Figure 4).

7. To “form” the final pass, place the

plywood wrapped in polyethylene

over the area to be filled. Carefully

spray the foam under the plywood,

holding the plywood down (Figure 5).

Wait about a minute for the foam

to rise to the underside of the

plywood and begin curing. Remove

the plywood, checking that the

foam is equal to the height of the

surrounding parapet.

8. In approximately 5 minutes, remove

any overspray with a roofing knife

(Figure 6). If additional shaping is

required, cut the cured foam with a

handsaw.

APPLy FINISh COATINg

(IF REquIREd)

Brush or roll a 30-40 mil quality

protective coating (similar to the

originally applied coating) within 3

hours after application.

dISPOSAL

1. Dispose of any foam waste and

empty FROTH-PAK

™

Foam Sealant

cylinders as a non-hazardous

waste (outlined in the operating

instructions) and in accordance

with local and state regulations.

2. Depressurize cylinders prior to

disposal.

Figure 2

Figure 3

Figure 5

Figure 4

Figure 6

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

Printed in U.S.A.

www.dowbuildingsolutions.com

Technical Information

1-866-583-BLUE (2583) (English)

1-800-363-6210 (French)

Sales Information

1-800-232-2436 (English)

1-800-565-1255 (French)

IN THE U.S.

THE DOW CHEMICAL COMPANY

200 Larkin

Midland, MI 48674

IN CaNada

DOW CHEMICAL CANADA ULC

450 – 1st St. SW . Suite 2100

Calgary, AB T2P 5H1

NOTICE: No freedom from any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for

determining whether products and the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal practices are in compliance with applicable laws and other

government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries

or regions. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted.

NO EXPRESS WARRANTIES ARE GIVEN EXCEPT FOR ANY APPLICABLE WRITTEN WARRANTIES SPECIFICALLY PROVIDED BY DOW. ALL IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

dow Polyurethane Foam Insulation and Sealants

CAUTION: When cured, these products are combustible and will burn if exposed to open flame or sparks from high-energy sources. Do not expose to temperatures above 240ºF (116ºC). For more information, consult MSDS,

call Dow at 1-866-583-BLUE (2583) or contact your local building inspector. In an emergency, call 1-989-636-4400 in the U.S. or 1-519-339-3711 in Canada.

FROTH-PAK™ spray polyurethane foam contains isocyanate, hydrofluorocarbon blowing agent and polyol. Read the instructions and Material Safety Data Sheets carefully before use. Wear protective clothing (including long

sleeves), gloves, goggles or safety glasses, and proper respiratory protection. Supplied air or an approved air-purifying respirator equipped with an organic vapor sorbent and a P100 particulate filter may be required to maintain

exposure levels below ACGIH, OSHA, WEEL or other applicable limits. Provide adequate ventilation. Contents under pressure.

Building and/or construction practices unrelated to building materials could greatly affect moisture and the potential for mold formation. No material supplier including Dow can give assurance that mold will not develop in any

specific system.