Troubleshooting – Pulsafeeder Pulsa Series 680 EN User Manual

Page 21

18

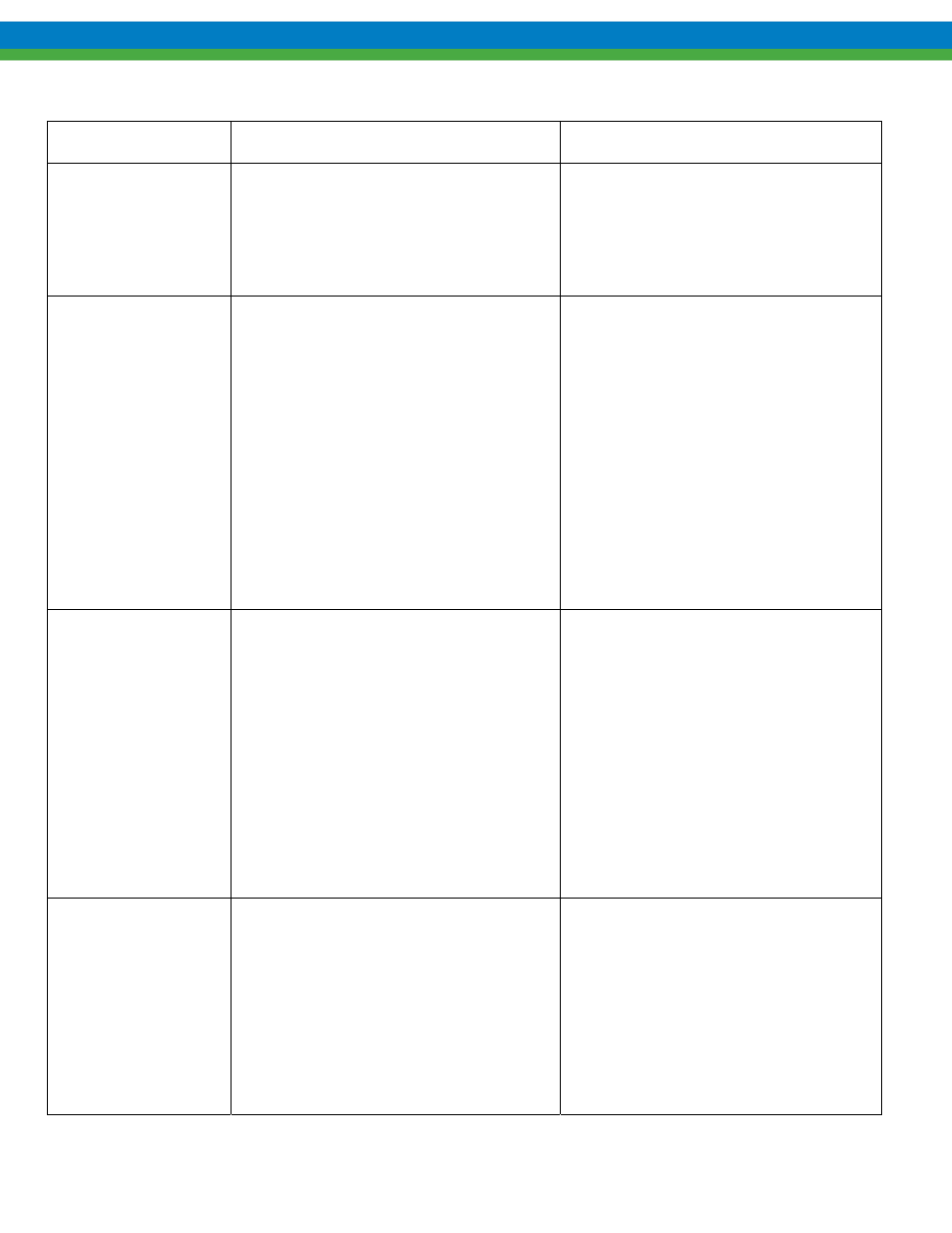

6. Troubleshooting

Difficulty Probable

Cause

Remedy

Pump does not start

1. Coupling disconnected.

2. Faulty power source

3. Blown fuse, circuit breaker

4. Broken wire

5. Wired improperly.

1. Connect and align

2. Check power source.

3. Replace-locate overload.

4. Locate and repair.

5. Check diagram.

No Delivery

wiring diagram.

1. Motor not running.

2. Supply tank empty.

3. Lines clogged.

4. Closed lined valves.

5. Ball check valves held open with

solids.

6. Vapor lock, cavitation.

7. Prime lost.

8. Strainer clogged.

9. Hydraulic system under-primed.

10. Check valves installed upside down.

1. Check power source.

2. Fill with liquid.

3. Clean and flush

4. Open pipeline valves.

5. Clean-inspect.

6. Increase suction pressure.

7. Reprime, check for leaks

8. Remove and clean.

9. Refer to “Repriming

Hydraulic System”.

10. See check valve illustrations.

Low Delivery

1. Motor Speed too low.

2. Check valves worn or dirty.

3. Hydraulic Bypass valve opening

each stroke.

4. Calibration system error.

5. Product viscosity too high.

6. Product cavitating.

1. Check voltages, hertz, wiring, and

terminal connections. Check

nameplate vs. specifications.

2. Clean, replace if damaged.

3. Refer to “Hydraulic Bypass Valve”

4. Evaluate and correct.

5. Lower viscosity by increasing

product temperature. Increase

pump size.

6. Increase suction pressure. Cool

product as necessary.

Delivery Gradually

Drops

1. Stroke adjustment creeping.

2. Check valve leakage.

3. Leak in suction line.

4. Fouled bypass or make-up valve.

5. Strainer fouled.

6. Product change.

7. Bypass leakage.

1. Consult factory. Replace worn

parts.

2. Clean, replace if damaged.

3. Locate and correct.

4. Refer to “Operation and

Maintenance”.

5. Clean or replace screen.

6. Check viscosity.

7. Correct for bypass valve leakage.

8.