DAK Americas ArrayEBM User Manual

Array, Ebm product information

Array

®

EBM

Product Information

polyethylene terephthalate resin

DAK Americas LLC

Gateway Corporate Center, Suite 210

223 Wilmington W Chester Pike• Chadds Ford, PA 19317

1-888-738-

2002 • fax: 610-558-7385 • www.dakamericas.com

PDS-B95A Rev 04/10

DAK Americas

ISO 9001:2008

#10004457

Product Description

Array

®

EBM polyethylene terepthalate (PET) resin is designed to have the melt strength and slow

crystallization rate required to produce large handle ware containers by extrusion blow molding. It

performs exceptionally well in the manufacture of thick walled containers where maintaining clarity and

neutral color are important. The higher intrinsic viscosity of this product gives the melt strength required

to maintain parison shape in continuous extrusion.

This product can be used with up to 50% in-plant regrind provided that the regrind has been dried.

In addition, DAK has designed Array

®

EBM to be recyclable with other PET products and this product

has met the APR Critical Guidance Document guidelines for PET

Food Contact

Array

®

EBM is ideally suited for food packaging applications and may be used in contact with food as

described on Food Contact Notification (FCN) 635 in full compliance with the Federal Food, Drug and

Cosmetic Act.

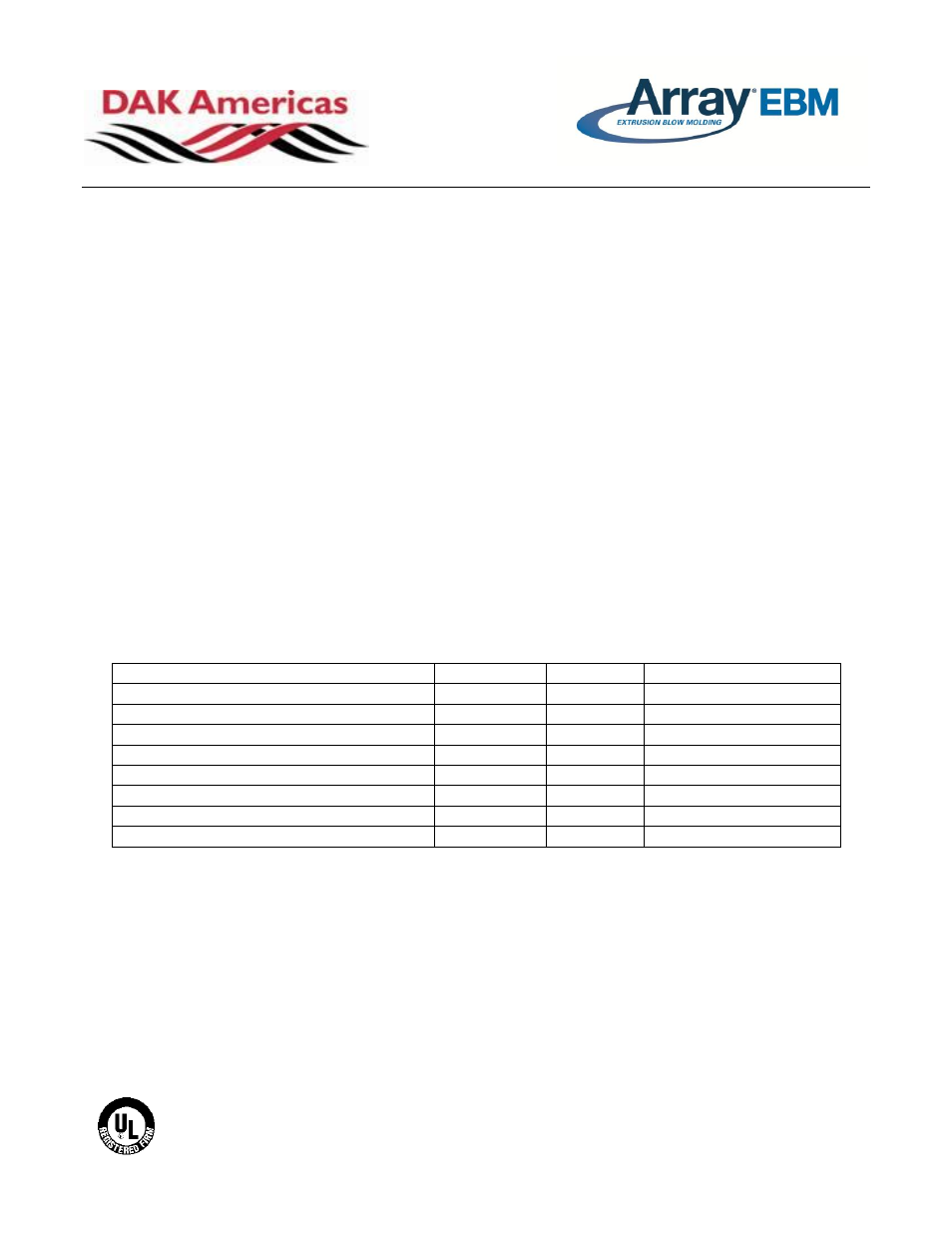

Sales Specifications (5860)

Property

Value

Unit

Test Method

Intrinsic Viscosity

1.10 +- 0.03

dL/g

DAK-QAR-SOP-0012

Color L*

81 +- 4

Hunter

LP-100

Color b*

-0.5+- 2.5

Hunter

LP-100

Acetaldehyde

2 max

ppm

DAK-QAR-SOP-0010

Moisture Content (as packaged)

0.25 max

Weight %

DAK-QAR-SOP-0013

Fines (as packaged, +24 Mesh Size)

0.10 max

Weight %

DAK-QAR-SOP-0014

Chip Size

49 to 59

Chips/g

DAK-QAR-SOP-0015

Melt Point

235 to 245

°C

DAK-QAR-SOP-0016

*This a development product. The specifications have not been finalized and are subject to change.

This product is spherical PET resin pellets made by the DAK Americas Melt-Tek® process.

These values represent the anticipated performance data for these polyester resins and intermediates; they are not intended to

be used as design data. We believe this information is the best currently available on the subject. It is offered as a possible

helpful suggestion in the experimentation you may care to undertake along these lines. It is subject to revision as additional

knowledge and experience is gained. DAK Resins makes no guarantee of results and assumes no obligation or liability

whatsoever in connection with this information. This publication is not a license to operate under, or intended to suggest

infringement of, any existing patents.

CAUTION: Do not use in medical applications involving permanent implantation in the human body. For other medical

applications, see “DAK Medical Caution Statement”.