DAK Americas Laser+ (B90A) User Manual

Laser, B90a), Product information

Laser+

®

(B90A)

polyethylene terephthalate resin

DAK Americas

ISO 9001:2008

#10004457

Product Description

Laser+

®

(B90A) polyethylene terephthalate (PET) resin is a copolymer formulated for conversion to

PET bottles by conventional single or

Typical Properties

Bi-orientation of Laser+

®

(B90A)

mechanical properties, including superior stress crack resistance. It performs

manufacture of CSD bottles made from thick

through the wall are important. DAK has reengineered Laser+

performance without sacrificing intrinsic viscosity (IV), to meet increasing demand for CSD applications.

Laser+

®

(B90A) offers superior heat absorption and processing control, even at higher blowing speeds.

A slower crystallization rate enables

Certification

Laser+

®

(B90A) is ideally suited for food packaging applications and is considered in compliance with

the Food and Drug Administration (FDA) Food

Health Products and Food Branch (HPFB) file KS 0510310

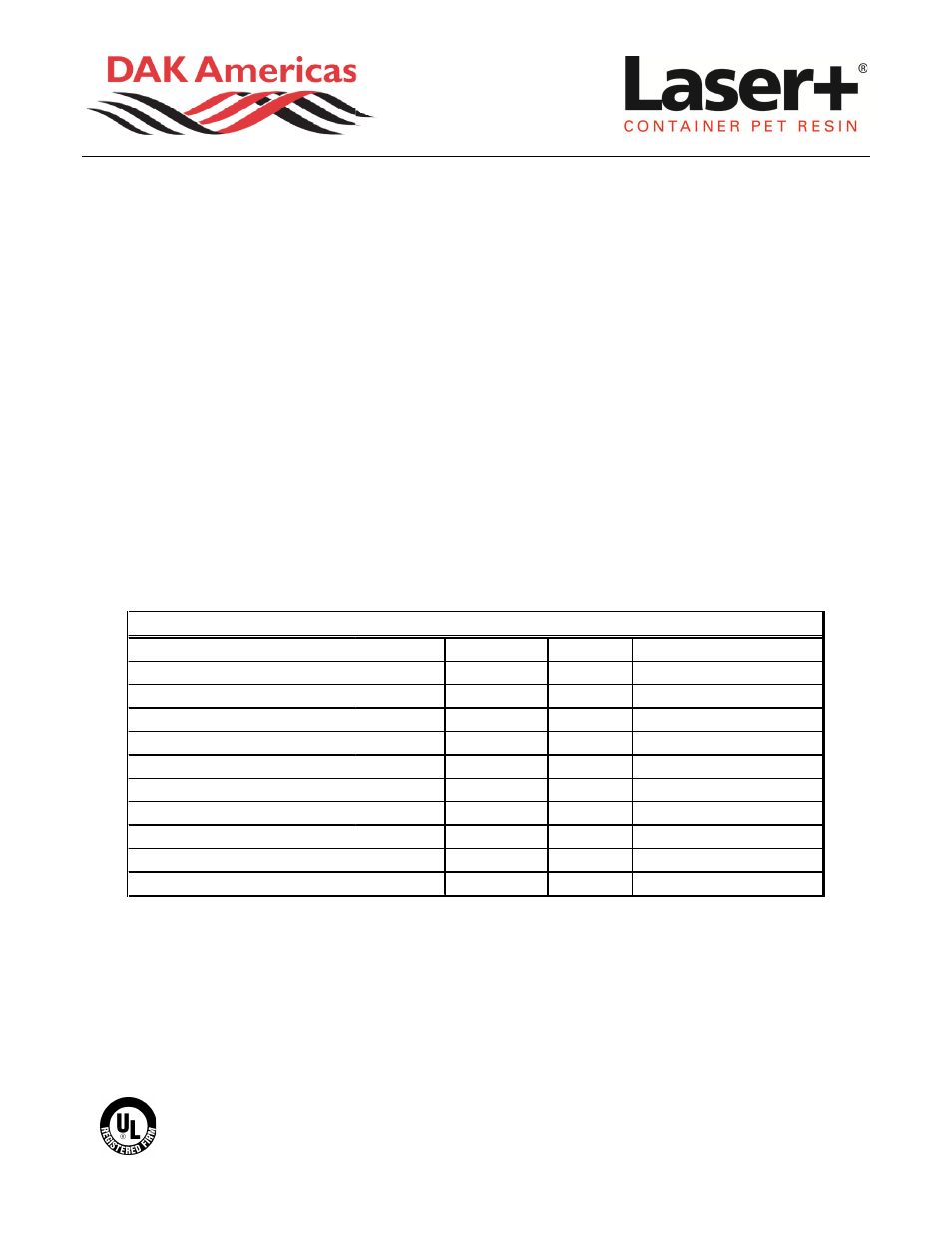

Sales Specifications

Property

Intrinsic Viscosity

Color L*

Color b*

Acetaldehyde

Moisture Content (as packaged)

Fines (as packaged, +24 Mesh Size)

Chip Size, nominal

Crystallinity

Partical Size, Shape (Flat Cylinder)

Melting Point, nominal

Bulk Density

These values represent the anticipated performance data for these polyester resins and intermediates; they are not intended to

be used as design data. We believe this information is the best currently available on the subject. It is offered as a poss

helpful suggestion in the experimentation you may care to undertake along these lines. It is subject to revision as additional

knowledge and experience is gained.

DAK Resins makes no guarantee of results and assumes no obligation or liability

whatsoever in connection with this information. This publication is not a license to operate under, or intended to suggest

infringement of, any existing patents.

CAUTION: Do not use in medical applications involving permanent implantation in the human body.

For other medical

applications, see “DAK Medical Caution Statement”.

Product Information

Gateway Corporate Center, Suite 210

223 Wilmington W Chester Pike• Chadds Ford, PA 19317

1-888-738-2002 • fax: 610-558-7385 • www.dakamericas.com

polyethylene terephthalate (PET) resin is a copolymer formulated for conversion to

PET bottles by conventional single or two-stage processing technology.

by injection/stretch blow molding provides optimal barrier and

mechanical properties, including superior stress crack resistance. It performs exceptionally well in the

manufacture of CSD bottles made from thick-wall preforms, where heatup rate and temperature profile

through the wall are important. DAK has reengineered Laser+

®

(B90A), improving acetaldehyde (AA)

rmance without sacrificing intrinsic viscosity (IV), to meet increasing demand for CSD applications.

offers superior heat absorption and processing control, even at higher blowing speeds.

on rate enables high injection molding output.

is ideally suited for food packaging applications and is considered in compliance with

the Food and Drug Administration (FDA) Food Contact Notification (FCN) 000635,

Health Products and Food Branch (HPFB) file KS 05103104 for PET polymers

Value

Unit

Test Method

0.84 ± 0.02

dL/g

DAK-QAR-SOP-0012

> 78

CIE

DAK-QAR-SOP-0011

-3.0 ± 2.0

CIE

DAK-QAR-SOP-0011

2 max

ppm

DAK-QAR-SOP-0010

Moisture Content (as packaged)

0.25 max

weight % DAK-QAR-SOP-0013

Fines (as packaged, +24 Mesh Size)

0.10 max

weight % DAK-QAR-SOP-0014

53 ± 5

chips / g DAK-QAR-SOP-0015

> 40

%

DAK-QAR-SOP-0016

Partical Size, Shape (Flat Cylinder)

3x3x2

mm

DAK-QAR-SOP-0017

241

ºC

DAK-QAR-SOP-0016

54.3

lb / ft³

DAK-QAR-SOP-0018

ticipated performance data for these polyester resins and intermediates; they are not intended to

be used as design data. We believe this information is the best currently available on the subject. It is offered as a poss

perimentation you may care to undertake along these lines. It is subject to revision as additional

knowledge and experience is gained.

DAK Resins makes no guarantee of results and assumes no obligation or liability

rmation. This publication is not a license to operate under, or intended to suggest

CAUTION: Do not use in medical applications involving permanent implantation in the human body.

For other medical

e “DAK Medical Caution Statement”.

Product Information

DAK Americas LLC

Gateway Corporate Center, Suite 210

223 Wilmington W Chester Pike• Chadds Ford, PA 19317

7385 • www.dakamericas.com

PDS-B90A 120313KH

polyethylene terephthalate (PET) resin is a copolymer formulated for conversion to

by injection/stretch blow molding provides optimal barrier and

exceptionally well in the

wall preforms, where heatup rate and temperature profile

, improving acetaldehyde (AA)

rmance without sacrificing intrinsic viscosity (IV), to meet increasing demand for CSD applications.

offers superior heat absorption and processing control, even at higher blowing speeds.

is ideally suited for food packaging applications and is considered in compliance with

, and Health Canada

Test Method

DAK-QAR-SOP-0012

DAK-QAR-SOP-0011

DAK-QAR-SOP-0011

DAK-QAR-SOP-0010

DAK-QAR-SOP-0013

DAK-QAR-SOP-0014

DAK-QAR-SOP-0015

DAK-QAR-SOP-0016

DAK-QAR-SOP-0017

DAK-QAR-SOP-0016

DAK-QAR-SOP-0018

ticipated performance data for these polyester resins and intermediates; they are not intended to

be used as design data. We believe this information is the best currently available on the subject. It is offered as a possible

perimentation you may care to undertake along these lines. It is subject to revision as additional

knowledge and experience is gained.

DAK Resins makes no guarantee of results and assumes no obligation or liability

rmation. This publication is not a license to operate under, or intended to suggest

CAUTION: Do not use in medical applications involving permanent implantation in the human body.

For other medical