Safety functions, Troubleshooting, User manual – Nilfisk-ALTO 580 P User Manual

Page 20: Hood safety switch, Emergency push-button, Hopper lifting cylinder safety valve

ENGLISH

USER MANUAL

18

FLOORTEC R 580 P

146 2603 000(1)2005-03 A

SAFETY FUNCTIONS

The machine is equipped with the following safety

functions.

HOOD SAFETY SWITCH

Turns off the engine when the hood (13, Fig. C) is open.

EMERGENCY PUSH-BUTTON

It is located in a position (8, Fig. B) that is easily accessible

for the Operator.

It must be pressed in case of emergency, to stop all the

machine functions.

HOPPER LIFTING/LOWERING AND

OVERTURNING ENABLING SWITCH

It is in the position (1, Fig. B) and must be pressed and

held to activate the hopper lifting/lowering and overturning

switches.

HOPPER LIFTING CYLINDER SAFETY

VALVE

It is located on the hopper lifting cylinder.

It stops the hopper in the position it has reached (without

possibility for it to lower accidentally) if the hydraulic

system piping, feeding the lifting cylinder should break.

PETROL ENGINE STOP DEVICE IN CASE

OF INSUFFICIENT ENGINE OIL LEVEL

The petrol engine is equipped with an internal devices that

checks the correct engine oil level and stops the engine if

the level should be insufficient.

TROUBLESHOOTING

(*): For the related procedure, see the Petrol Engine User

Manual.

For further information, refer to the Service Manual,

available at any Nilfisk-Alto Service Center.

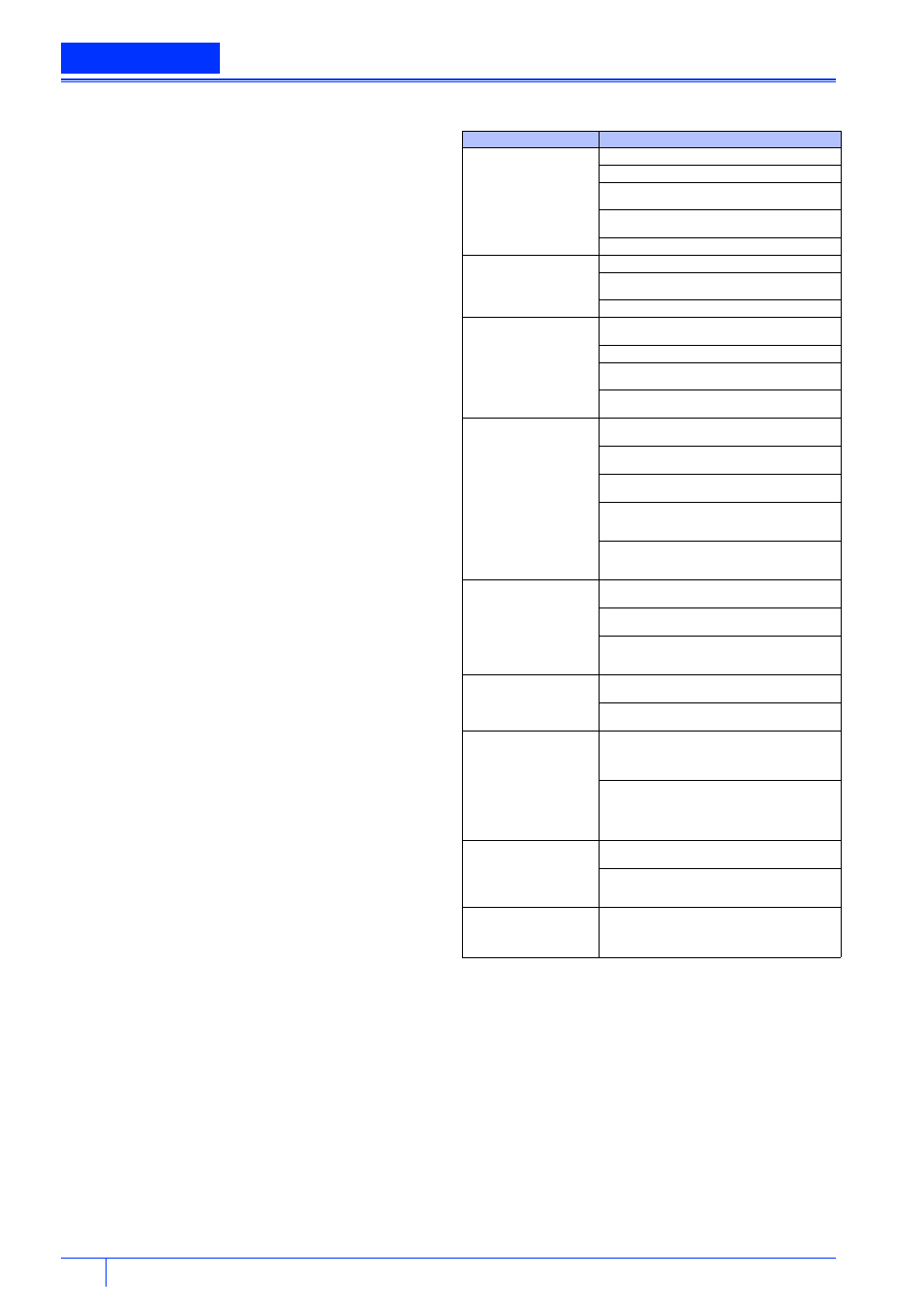

TROUBLE

REMEDY

The petrol engine does not

start if activated with the

ignition key.

Check that the hood (13, Fig. C) is closed.

Check that the engine oil level is sufficient (*).

Check that the petrol tank (8, Fig. V) contains the

appropriate kind of fuel.

Check that the petrol reaches the carburettor and

the petrol filter is clean (*).

Check that the spark plug produces a spark (*).

The petrol engine stops

during operation

Check that the engine oil level is sufficient (*).

Check that the petrol tank (8, Fig. V) contains the

appropriate kind of fuel.

Check that the petrol filter is clean (*).

The machine collects little

debris/dust.

Check that the dust filter (3, Fig. C) is not

clogged.

Check that the hopper (4, Fig. C) is not full.

Check that the skirts (16, 17, 18, 19, Fig. C) are

not broken or incorrectly adjusted.

Check that the brooms (10, 11, 12, Fig. C) are at

the correct height.

When the forward/reverse

gear pedal is pushed the

machine does not move, or

it moves slowly

Check that the parking brake (22 with 15, Fig. B)

has been released.

Check that the engine throttle lever (24, Fig. B) is

on MAX (maximum speed).

Check that the hydraulic oil level in the tank (6,

Fig. V) is correct.

Check that the centrifugal pulley (petrol

engine-drive pump coupling joint) operates

properly.

Check that the forward speed pedal is correctly

adjusted and it activates the drive pump

correctly.

The hopper does not lift

Check that the hydraulic oil level in the lifting unit

tank (19, Fig. V) is correct.

Check that the control electrical connectors are

correctly connected.

Check that the hopper is not excessively loaded

(hydraulic lifting capacity exceeded). In this case,

unload the hopper.

The hopper does not

overturn

Check that the hopper is lifted from the ground at

an height greater than 270 mm.

Check that the control electrical connectors are

correctly connected.

The hopper does not lower Before lowering the hopper by means of the

related switch (11, Fig. B), check that the hopper

has returned to the horizontal position by means

of the related switch (12, Fig. B).

Wait a few minutes to allow the lifting cylinder

hydraulic oil to flow out through its interior

parachute valve; if the valve is stuck, it could be

necessary to press the lowering switch (12, Fig.

B) again.

The brooms do not rotate

correctly.

Check that the broom control belt tension is

correct.

Turn the throttle lever (24 fig. B) to MAX

(maximum speed), and check that the centrifugal

pulley engages.

With the engine

compartment (13, Fig. C)

hood lifted, the petrol

engine keeps running.

Malfunction of the hood safety micro-switch.

Please contact the Nilfisk-Alto Service Center.