Maintenance, User manual, Scheduled maintenance table – Nilfisk-ALTO 580 P User Manual

Page 13

USER MANUAL

ENGLISH

146 2603 000(1)2005-03 A

FLOORTEC R 580 P

11

MAINTENANCE

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

The following chart provides the scheduled maintenance. The intervals shown may vary according to particular working

conditions, which are to be defined by the person in charge of the maintenance.

All scheduled or extraordinary maintenance operations must be performed by qualified personnel, or by an authorised

Service Center.

This manual describes only the easier and most common maintenance procedures.

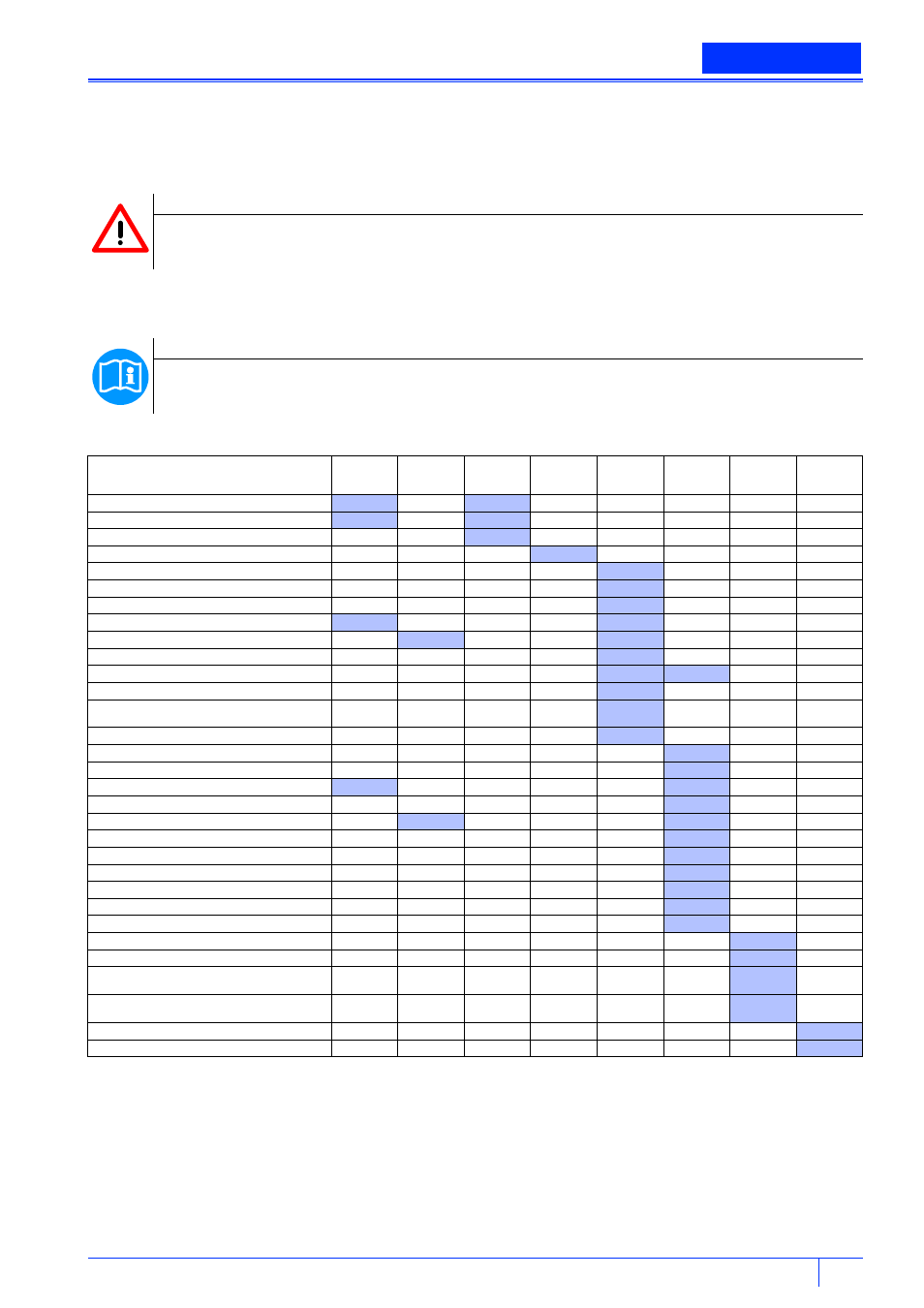

SCHEDULED MAINTENANCE TABLE

(1): For the related procedure, see the Service Manual

(2): or every year.

(3): or more often in dusty areas.

(4): maintenance operations to be performed by an authorized Briggs & Stratton dealer.

(5): if considered necessary by the person in charge of the maintenance.

(6): replace hydraulic oil for the first time after 500 hours, then after 2,000 hours or every year.

WARNING!

Maintenance operations must be carried out when the machine is off (on/off switch key removed).

Moreover, carefully read the instructions in the Safety chapter.

NOTE

For other maintenance procedures contained in the Scheduled Maintenance Table or for extraordinary

maintenance operations see the specific Service Manual that can be consulted at any Service Center.

Maintenance operation

On delivery

After the

first 5 hours

Every 10

hours or

before use

Every 25

hours

Every 50

hours

Every 100

hours

Every 200

hours

Every year

Engine oil level check

Battery fluid level check

Side and main broom height check

Engine air pre-filter cleaning

(3)

Frame dust filter cleaning and integrity check

Hopper lifting system hydraulic oil level check

Drive system hydraulic oil level check

Skirt height and operation check

Engine oil change

(2)

Filter-shaker operation check

(1)

Brake adjustment

(1)

Petrol filter cleaning

Drive wheel gearing chain tension check and

cleaning

(1)

Spark screen check and cleaning

Closed pocket filter cleaning and integrity check

Vacuum hose integrity check

(1)

Driving belt tension visual check

(1)

(1)

Ignition spark plug check/cleaning

Nut and screw tightening check

(1)

(1)

Steering chain tension check and cleaning

(1)

Safety device operation check

(1)

Engine speed check

(1)

Engine air filter element maintenance

(3)

Spark plug replacement

(2)

Engine cooling system cleaning

(2)

Driving belt replacement

(1) (5)

Hopper gasket integrity check

(1)

Hopper lifted position control micro-switch

adjustment check

(1)

Hopper horizontal position control micro-switch

adjustment check

(1)

Engine valve clearance check/adjustment

(4)

Hydraulic oil change

(1)(6)