Testing sensors, Crankshaft/camshaft position sensors, What is it and how is it used – Actron CP9087 User Manual

Page 54

2-46

Testing Sensors

Section 2

What is It

and

How is It

Used?

— The computer needs to know rotational speed (or

position) of the engine crankshaft/camshaft for controlling

ignition and fuel injector systems. If the computer is

handling a Distributorless (or Direct) ignition system or

controlling the operation of individual fuel injectors, it also

needs to know when cylinder #1 is active. The sensors have

various names such as:

Crankshaft Position, Crank Angle,

Flywheel, Distributor Pick-Up, Camshaft Position, Cylinder,

TDC and RPM.

— Similar sensors are used in anti-lock brake and electroni-

cally shifted transmission systems. These sensors have

names such as:

Wheel Speed, Vehicle Speed and

Driveshaft.

— The sensors come many styles using different connectors.

Sometimes an assembly contains more than one sensor.

Other versions combine two functions into a single sensor

(usually camshaft position and cylinder #1 identification).

— The most common sensor types are

Magnetic Reluc-

tance and Hall Effect. These are described below along with

Optical types which are in limited use.

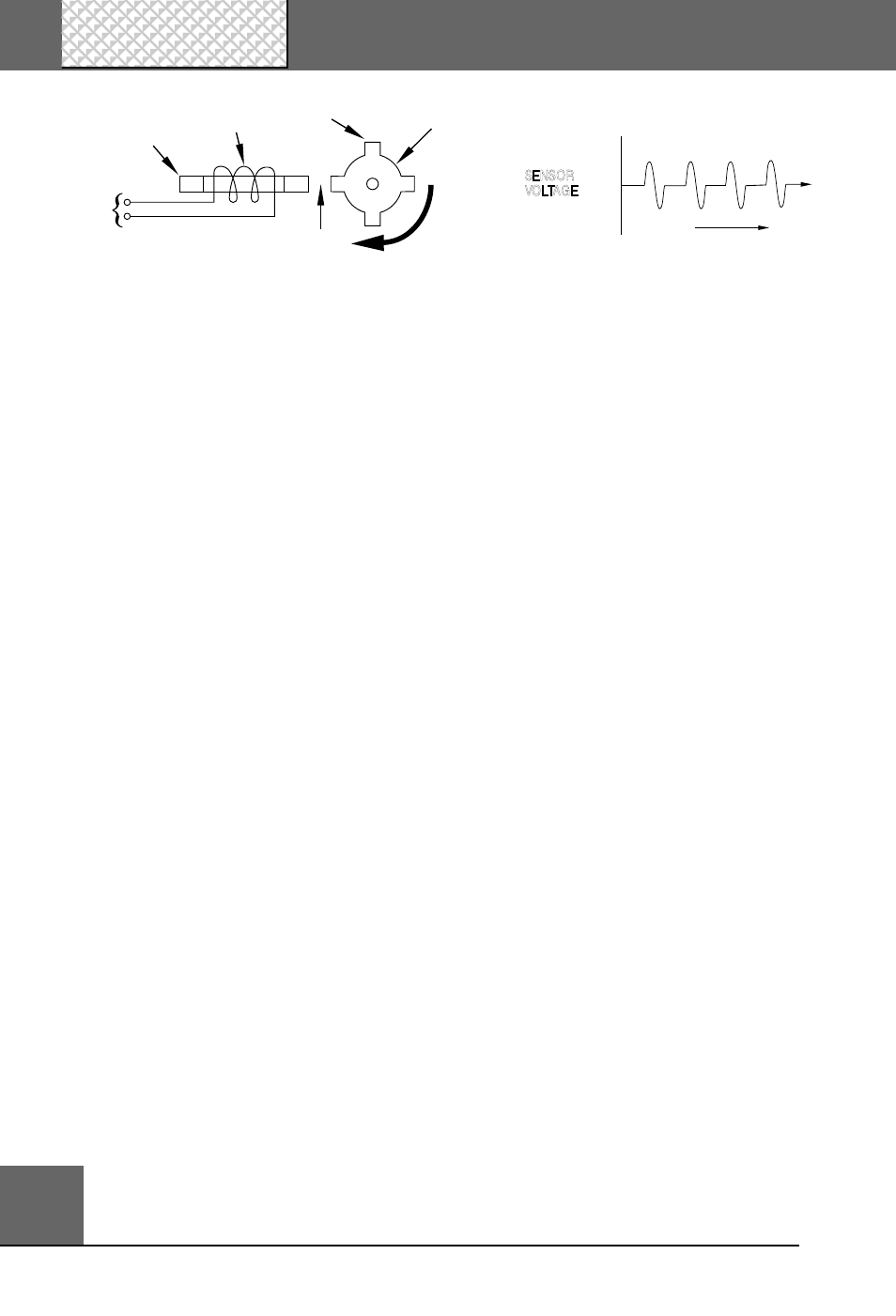

The basic reluctance sensor consists of a permanent

magnet with a coil of wire wrapped around it. Nearby the

sensor is a toothed ring made of iron or steel (sometimes

called a “reluctor”). The ring is attached to a rotating

component such as the crankshaft or camshaft. Whenever

a tooth from the ring passes by the sensor, it attracts the

magnetic field lines surrounding the magnet. As the field

lines move, they pass through the wire coil and generate a

small voltage pulse (magnetic induction principle). Thus a

voltage pulse is generated every time a tooth passes by

the sensor coil.

• Magnetic

Reluctance

Rotation

Reluctor Ring

Tooth

Wire Coil

Magnet

To

Computer

Air Gap

N

S

Crankshaft/Camshaft Position sensors

Reluctance Sensor Operation

Typical Sensor Signal Voltage

ROTATION

Positive

Negative

Zero

SENSOR

VOLTAGE