Maintenance works, Clean filter at the water connection, Clean filter at the detergent suck hose – Karcher HD 10-16-4 Cage Ex User Manual

Page 20: Oil change, Maintenance schedule, Troubleshooting, Appliance is not running, Device is not building up pressure, High pressure side is leaky, High pressure pump is vibrating

– 7

Unscrew the filter casing, remove the

filter, clean it and replace it.

Take out detergent suck hose.

Clean filter in water and reinstall.

For oil type refer to technical specifica-

tions.

Turn out the oil drain screw.

Drain the oil in a collection basin.

Screw in oil drain plug.

Slowly fill in new oil until the "MAX"

marking on the oil container.

Note

Air pockets must be able to leak out.

You can rectify minor faults yourself with

the help of the following overview.

If in doubt, please consult the authorized

customer service.

ƽ

Risk of injury

Always switch off the appliance and pull out

the mains plug before care and mainte-

nance work.

ṇ

Warning

Repair work and work on electrical compo-

nents may only be performed by the author-

ized customer service in non-explosion

danger areas.

–

No power

Check the plugs and sockets.

Check whether the voltage indicated on

the type plate corresponds to the volt-

age of the socket.

Check the mains connection cable for

damages.

–

Engine is overheated

Switch off appliance and let it cool

down. Remove the cause of the prob-

lem. Turn on the appliance again.

–

Wrong nozzle

Check nozzle for correct size (see tech-

nical specifications).

–

Air within the system

Vent pump:

Unscrew the nozzle. Switch on the ap-

pliance and let it run until the water ex-

iting from the spray pipe is bubble-free.

Switch off the appliance and fit the noz-

zle again.

–

Nozzle is blocked/ washed out

Clean/ replace nozzle.

–

Filter at the water connection is dirty

Clean filter at the water connection.

–

Amount of water supply is too low.

Check water supply level (refer to tech-

nical data).

–

Pipe inlets to pump are leaky or blocked

Check all supply lines to the high-pres-

sure pump for leaks or blockages.

3 drops per minute are permitted and

can come out from the lower side of the

appliance. Call Customer Service if

there is heavy leakage.

–

Pipe inlets to pump are leaky or blocked

Check all supply lines to the high-pres-

sure pump for leaks or blockages.

–

Air within the system

Maintenance Works

Clean filter at the water connection

Clean filter at the detergent suck hose

Oil change

Dispose of old oil ecologically or turn in at

a gathering point.

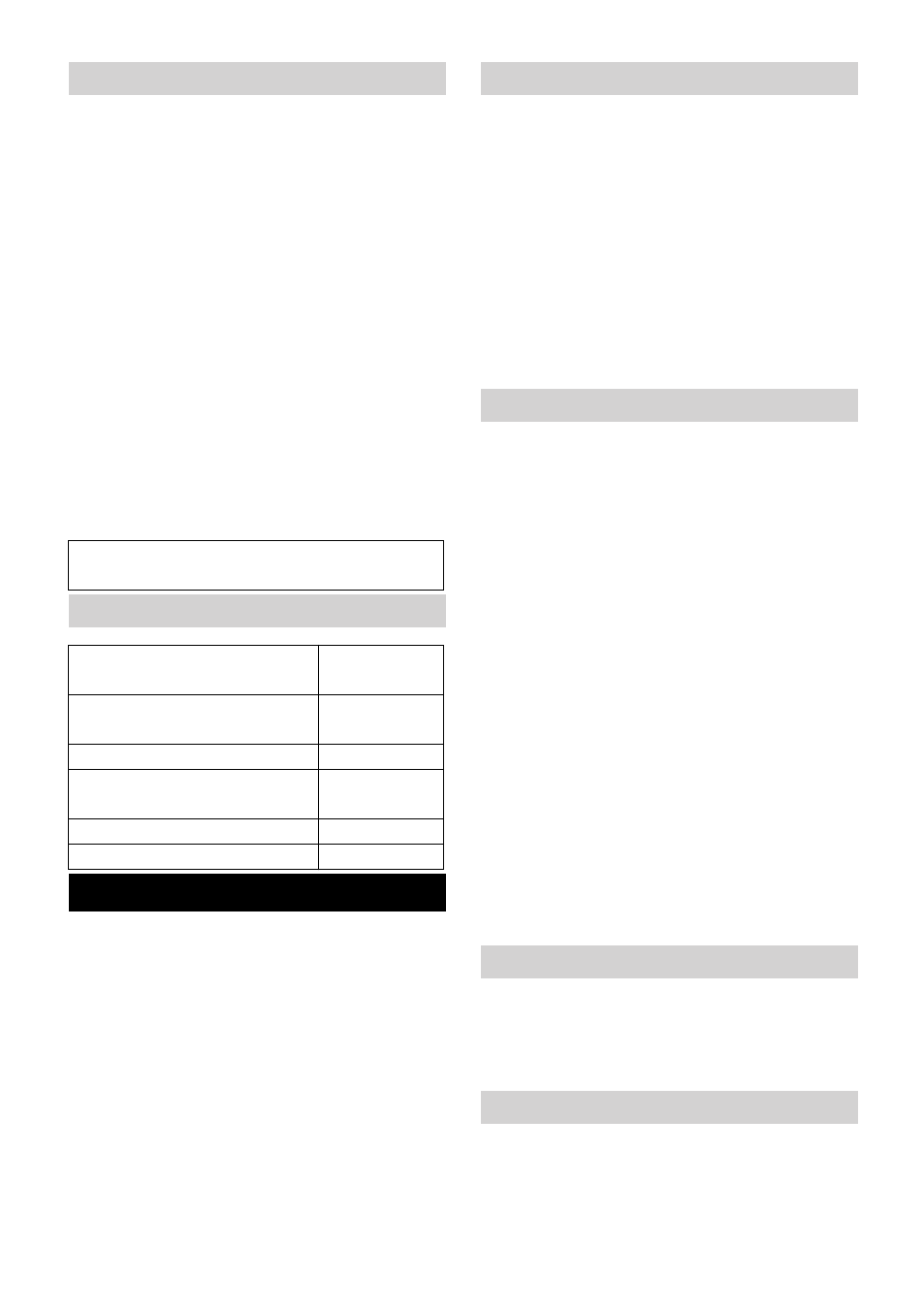

Maintenance schedule

Wear parts

Operating

hours

High-pressure/low-pres-

sure seals

1000 h

Suction/pressure valves

1000 h

O-rings/support rings of the

overflow valve

1000 h

Ball bearing of the pump gear 2000 h

Oil races, shaft seal

2000 h

Troubleshooting

Appliance is not running

Device is not building up pressure

High pressure side is leaky

High pressure pump is vibrating

20

EN