ROTHENBERGER RE 17 Dreigas-Anlage AMS 5/5 User Manual

Page 18

14

ENGLISH

Î

Open the shut-off valve (7) on the oxygen pressure regulator, the adjustment valve for

oxygen (16) on the handle or hand-held cutting torch (15) and the cutting oxygen valve (22)

on the cutting attachment (20) or hand-held cutting torch.

Î

Adjust the operating pressure by turning the pressure adjusting valve (5) on the cylinder

pressure regulator for oxygen (3) (refer: technical data).

Î

Close cutting oxygen valve (22) and adjustment valve for oxygen (16).

Î

Open the shut-off valve (8) on the fuel

Î

gas pressure regulator and adjust the fuel gas pressure by turning the pressure adjusting valve

(6) (refer: technical data)

Attention

It is important, however, to ensure that the line pressure is at least 0.2 bar higher than the

values mentioned in section 2!

Ignition and adjustment of the flame

Î

First open the adjustment valve for oxygen (16) on the handle or hand-held cutting torch (15)

and then open the heating oxygen valve (21) on the cutting attachment (20) and the

adjustment valve for fuel gas (17) on the handle or hand-held cutting torch (15).

Î

Ignite the escaping gas mixture immediately. Adjust the flame to neutral (same as welding

flame) by making readjustments on the heating oxygen valve (21) or adjustment valve for

oxygen (16) and adjustment valve for fuel gas (17).

Î

Fully open the cutting oxygen valve (22) and readjust the oxygen pressure (refer: technical

data) as required. Adjust the flame to neutral again. Close the cutting oxygen valve (22)

again

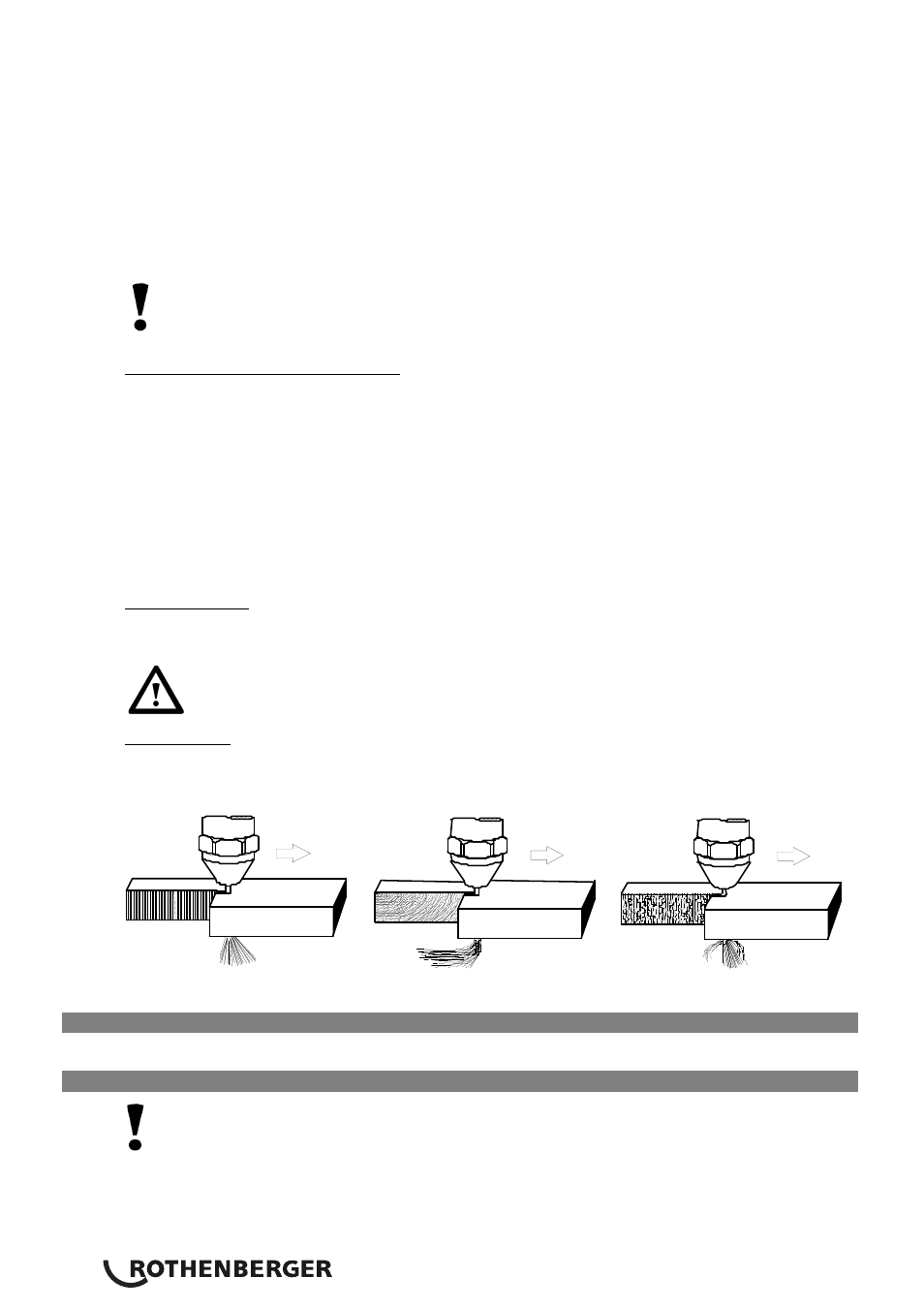

Beginning to cut

Î

Put the torch in first cut position and use the heating flame to heat up the workpiece to

ignition temperature, approximately bright red

Caution! Do not melt down the material! Then open the cutting oxygen valve (22) and

move the torch in the cutting direction.

Cutting speed

The correct cutting speed can be recognized by the slag discharge, vertical flying sparks and

cutting noise

3.3 Accessories

The relevant accessories and an order form can be found from Page 70 onwards.

4

Transport and storage

For transport, the oxygen tank valve and the Maxi gas cartridge must be closed.

After finishing the welding work: With the gas cartridge valve and acetylene tank valve

closed, cut off the gas and oxygen valve at the handle, and allow the remaining gas to

escape (Gauge display note). This discharges the hoses and the oxygen pressure

regulator.

Remove the acetylene and oxygen pressure regulator. Screw off the gas cartridge valve of the

Maxi gas cartridge. The hoses can be connected to the oxygen pressure regulator and the gas

correct

to high

to low