ROTHENBERGER RE 17 Dreigas-Anlage AMS 5/5 User Manual

Page 17

ENGLISH

13

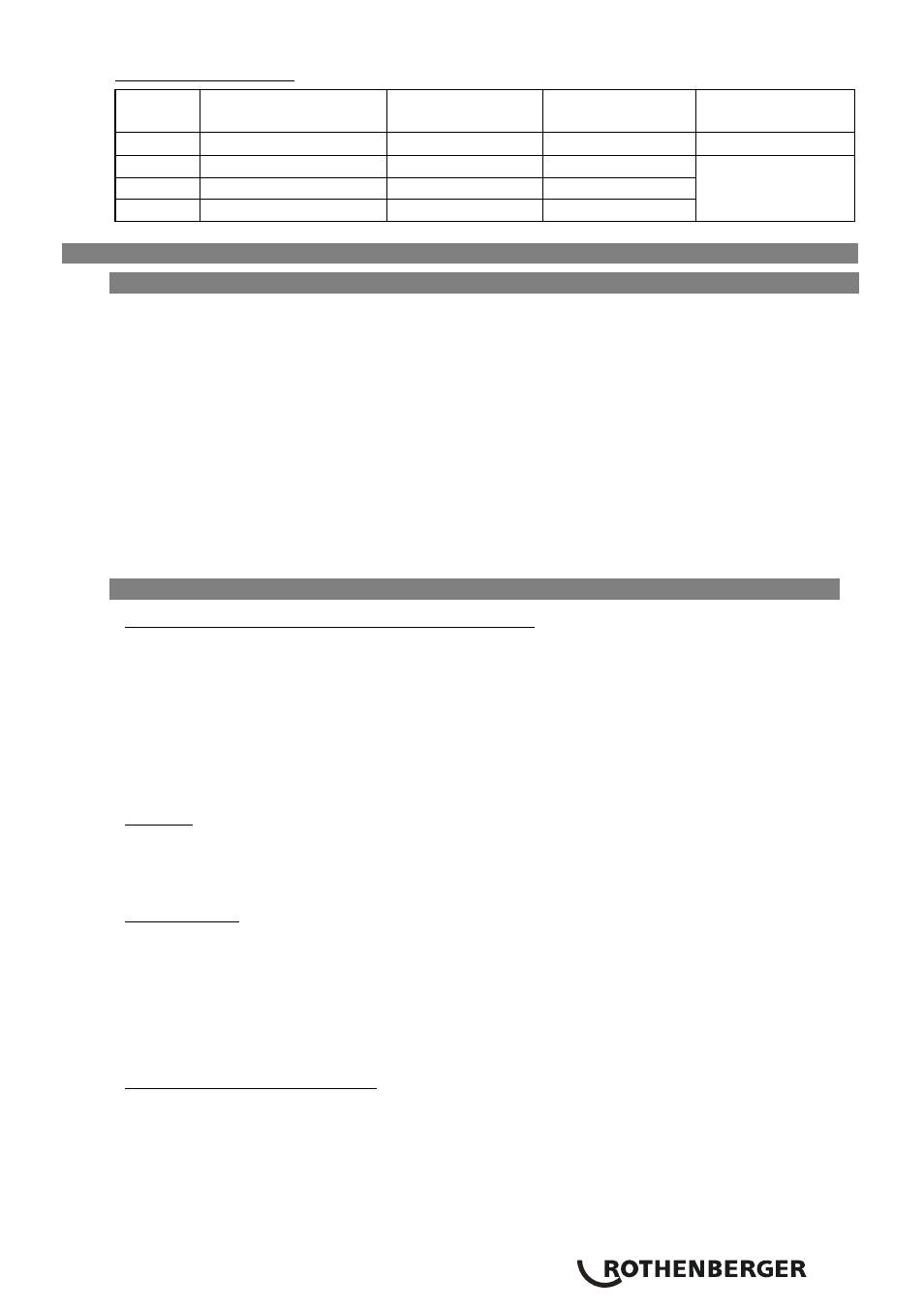

Flame cutting nozzles

Nozzle Cutting

size Article-No.

Oxygen

pressure

Acetylene-

pressure

Size

[mm]

[bar]

[bar]

1/32 3-

6 3.5341 2,0

3/64 6-

20 3.5344 2,5

1/16 20-

75 3.5345 3,5

≥

0,5

3

Functions

3.1

Overview

A

1

Acetylene cylinder

8

Twin tubing bundle

15

Cutting nozzle

2

Oxygen cylinder

9

MAXIGAS 400

16

Torch key

3

Acetylene cylinder

welding regulator

10

RE17 handle

17

Gas control valve

MAXIGAS

4

Oxygen cylinder

welding regulator

11

RE17 wing lever

18

Tube adapter

MAXIGAS

5

Transport carriage

12

RE17 welding inserts

19

Safety lighter

6

Rubber caps red

13

Nozzle cleaner

20

Replacement flints

7

Rubber caps blue

14

Heating nozzle

3.2

Operational

description

B

Welding with high-performance welding nozzles:

Basically, the welding flame should burn neutrally (the gas mixture is balanced), and its size

should be adjusted to the material thickness, the weld shape, the welding position and the

heat conductivity of the material.

When welding steel at greater thicknesses, open both valves wide, and when welding thinner

welding steel plates close the valves somewhat.

Preheat the material and welding rod. As soon as the metal begins to melt on both sides of

the seam, introduce the welding rod. Make sure that the welding area heats evenly. Run the

burner in half circles around the welding rod.

Brazing:

Clean the connecting surfaces polish them and round off the edges. Preheat the brazing

area. Place the tip of the soldering rod onto the soldering area, melt a drop of solder, and

spread it under constant flame movement.

Torch cutting:

Î

Select the torch cutting nozzles (23) according to the workpiece thickness (refer: technical

data) and then screw them until leaktight into the torch tip of the cutting attachment (20) or

hand held cutting torch (15).

Î

Using a suitable wrench tighten firmly the nozzle retaining nut in the torch tip. Use clean,

undamaged ROTHENBERGER original torch cutting nozzles only. Make sure that the sealing

surfaces on the nozzles and torch tip are in perfect condition.

Adjusting the operating pressures

Î

First, keep the adjustment valves for oxygen and fuel gas (16 and 17) on the handle or hand-

held cutting torch closed.

Î

Slowly open the cylinder valves (1 and 2) or the tapping point valves in the distribution line (9

and 10).