Troubleshooting maintenance – ROTHENBERGER Hand Roll Groover 1 - 12 User Manual

Page 16

16

ESPAÑOL

16

ENGLISH

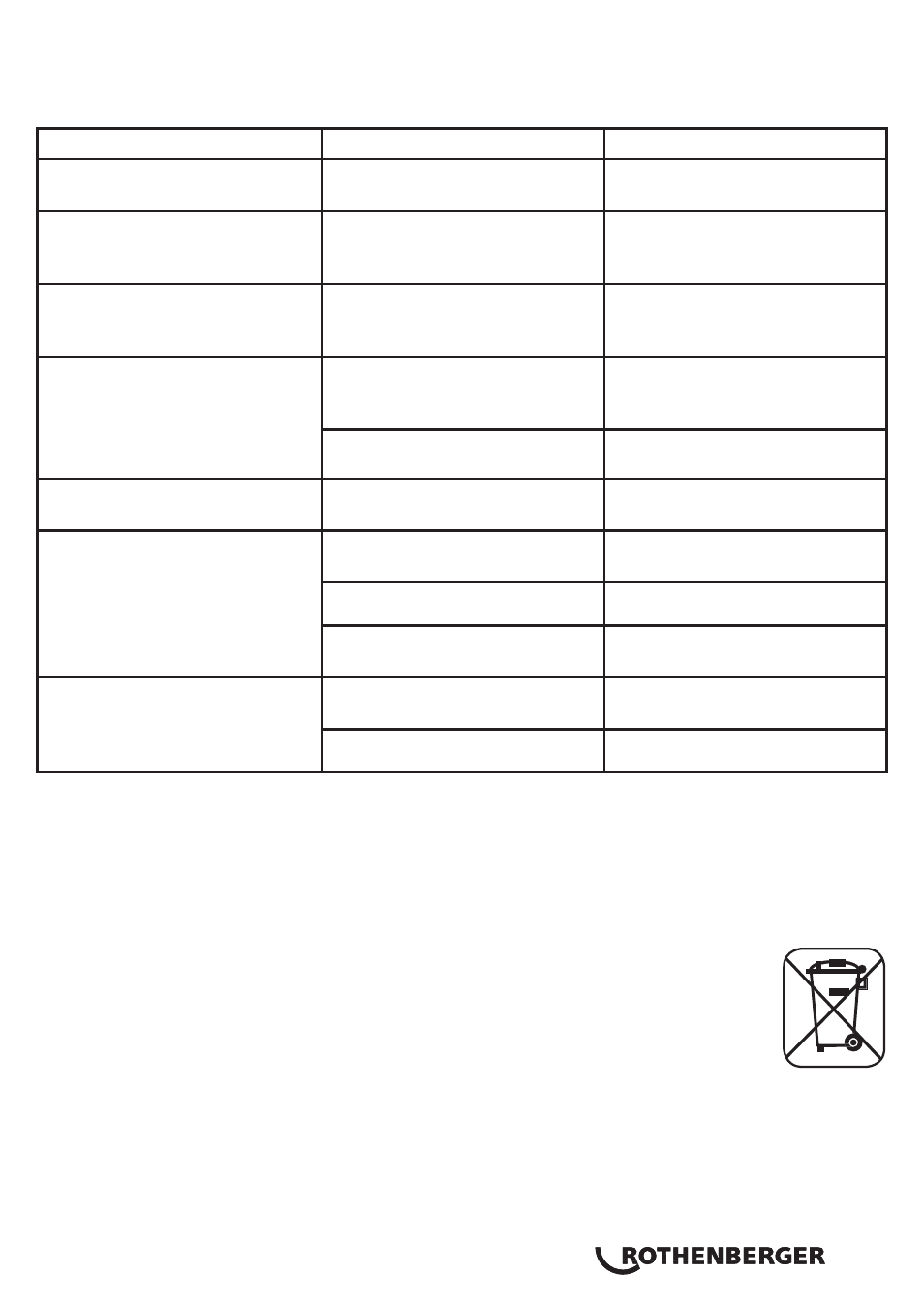

Problem

Possible cause

Solution

The groove is too narrow or too

wide

The roller set does not correspond

to the tube diameter

Replace the roller set for one which

corresponds to the tube diameter

The groove zigzags

The groove is not parallel to the surface

of the tube end

The tube has not been cut square

Cut the tube square

The groove diameter is not uniform

throughout the entire circumference

of the tube

The tube is elliptic

Use a circular tube

The tube slides or slips in the lathe

screw

The lathe screw fluting is blocked

by metal, worn or flat

Clean or replace the lathe screw

Poor grooving force

Tighten the guide screw

The groove diameter is not correct

The depth has not been regulated

properly

Regulate the depth using the

gauges

The machine sways from side to

side in the lathe screw

The machine is not properly

positioned on the tube

Reposition the machine in the tube

against the edge of the lathe screw

The tube has not been cut square

Cut the tube square

Wrong manual feeding speed, too

slow

Feed the upper roller inside the

tube more quickly

The machine does not knurl the

tube

The tube is too thick for the

machine's maximum capacity

Check the machine's capacity table

Tube material too tough

Check the machine's capacity table

TROUBLESHOOTING

mAINTENANCE

maintenance instructions

- The lubricator for the roller shaft must be lubricated once a month and each time the roller set is replaced.

- Add lubricating grease to the pin bearings prior to reassembling them.

- Lubricate the guide screw.

- Keep the upper rollers clean.

- Keep the guide screw clean.

Service and repairs

This grooving machine must be serviced and repaired by qualified technicians. If the machine does not operate

correctly the user must contact the manufacturer for repair.