ROTHENBERGER PORTACUT 185 User Manual

Page 24

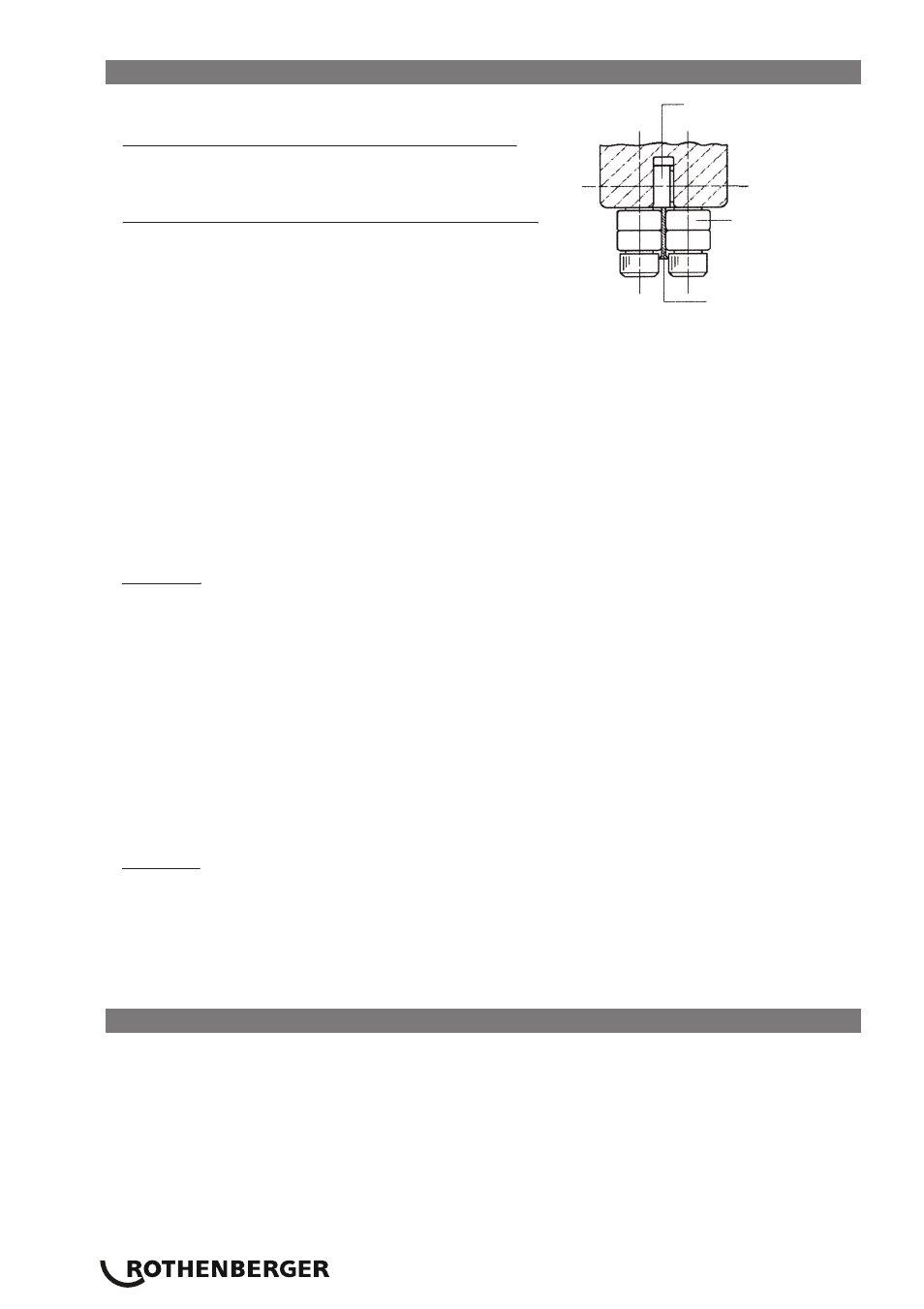

5.2 Correction procedure for oblique cutting (Fig. E)

If the saw blade cuts obliquely, check for worn bea-

If the saw blade cuts obliquely, check for worn bea

rings in the blade guide heads.

When the back stopper ball bearing (1) is worn:

When the back stopper ball bearing (1) is worn:

pp

g ( )

Remove the blade stopper bearing

Remove the blade stopper bearing (2)

(2), remove the adjust-

, remove the adjust

ment bolt (3), and change the back stopper ball bearing. (For

bolt F and R)

When the blade stopper ball bearing (2) are worn:

When the blade stopper ball bearing (2) are worn:

pp

g ( )

Change all the blade stopper ball bearings. (For bolt F and R)

Change all the blade stopper ball bearings. (For bolt F and R)

The bearing will come off by removing the U nuts (4) under

the bearings.

If oblique cutting still persists after bearing replacement,

If oblique cutting still persists after bearing replacement,

make corrections in the following procedure:

• Prepare a pipe.

Prepare a pipe.

• Cut it once in an ordinary state. (Mark the pipe end faces to indicate which side is top or

Cut it once in an ordinary state. (Mark the pipe end faces to indicate which side is top or

bottom.)

bottom.)

• After rotating the pipe a half turns, cut it once more to a length of about 5 mm. (Mark the

After rotating the pipe a half turns, cut it once more to a length of about 5 mm. (Mark the

pipe end to indicate which side is top or bottom and right or left.)

Immediately after cutting, fragments are hot. Do not touch them directly with hands! Wait for

Immediately after cutting, fragments are hot. Do not touch them directly with hands! Wait for

a while or hold the pipe with a cloth. Otherwise you may get burned.

• Measure the top, bottom, right and left lengths of that butt end with a rule, yard stick or the

Measure the top, bottom, right and left lengths of that butt end with a rule, yard stick or the

like. A difference between these lengths indicates an oblique cut. An oblique cut value is a half

of this difference.

• When there is a difference between top and bottom lengths, detach saw blade referring to

When there is a difference between top and bottom lengths, detach saw blade referring to

5.1.1. Replacing the saw blade.

Type BSR:

Type BSR:

yp

• Loosen the two bolts (5) of blade guide (6) and the lock nut (7) of blade guide head, and turn

Loosen the two bolts (5) of blade guide (6) and the lock nut (7) of blade guide head, and turn

the adjustment bolt clockwise or counter clockwise to adjust the angle of the blade guide

head.

When the top length is larger: Turn the adjustment bolt counter clockwise.

When the top length is larger: Turn the adjustment bolt counter clockwise.

When the bottom length is larger: Turn the adjustment bolt clockwise.

When the bottom length is larger: Turn the adjustment bolt clockwise.

* A half turn of the adjustment bolt allows adjustment of about 0.8 mm (For 4“ pipe).

A half turn of the adjustment bolt allows adjustment of about 0.8 mm (For 4 pipe).

Always adjust the blade guides F and R to the same value. (After adjustment, always make sure

Always adjust the blade guides F and R to the same value. (After adjustment, always make sure

that the end of the adjustment bolt makes contact with the surface of the blade guide.)

* The correction procedure is also given on the inside of the front cover.

The correction procedure is also given on the inside of the front cover.

Install saw blade in order of Fig. D-1 (5.1.1. Replacing the saw blade).

Install saw blade in order of Fig. D 1 (5.1.1. Replacing the saw blade).

• Install saw blade referring to 5.1.1. Replacing the saw blade.

Install saw blade referring to 5.1.1. Replacing the saw blade.

• Confirm the oblique cutting according to the procedure as described before.

Confirm the oblique cutting according to the procedure as described before.

Type BSP:

Type BSP:

yp

• Loosen the bolt (1) and lock nut (2) of flat vice-R (3) and turn the adjustment bolt (4) to adjust

Loosen the bolt (1) and lock nut (2) of flat vice R (3) and turn the adjustment bolt (4) to adjust

the

angle of the flat vice-R.

When the blade guide head F side longer: Turn the adjustment bolt clockwise.

When the blade guide head F side longer: Turn the adjustment bolt clockwise.

When the blade guide head R side longer: Turn the adjustment bolt counter clockwise.

When the blade guide head R side longer: Turn the adjustment bolt counter clockwise.

* One turn of the adjustment bolt allows adjustment of about 1 mm.

One turn of the adjustment bolt allows adjustment of about 1 mm.

Measure the amount of the oblique cutting.

Measure the amount of the oblique cutting.

5.3 Daily Inspection and Maintenance

• Immediately replace power plug, power cord and extension cord, if damaged.

Immediately replace power plug, power cord and extension cord, if damaged.

• Check the saw blade for chipping or damage. Replace if chipping is found. (For the saw blade

Check the saw blade for chipping or damage. Replace if chipping is found. (For the saw blade

replacing procedure, refer to 5.1.1. Replacing the saw blade)

• Check the blade stopper ball bearings and back stopper ball bearings. If they are not set

Check the blade stopper ball bearings and back stopper ball bearings. If they are not set

correctly, cutting accuracy will decline. When the ball bearings are worn, replace them as soon

as

possible.

(Replace all the bearings on both sides.)

• Check for loose fitting screws of parts. If used loosened, danger can result. Retighten them.

Check for loose fitting screws of parts. If used loosened, danger can result. Retighten them.

• Completely wipe off dirt and chips from the machine.

Completely wipe off dirt and chips from the machine.

• Coat the machine with rust preventive grease when the machine is not used for a long period

Coat the machine with rust preventive grease when the machine is not used for a long period

of time.

pper, ball

pper ball

Back stop

bearing

ade stopper,

d

t

Bla

all bearing

ba

b

ba

b

b

blade

blade

Saw b

ENGLISH

20