American Dryer Corp. ML-75DII User Manual

Page 36

32

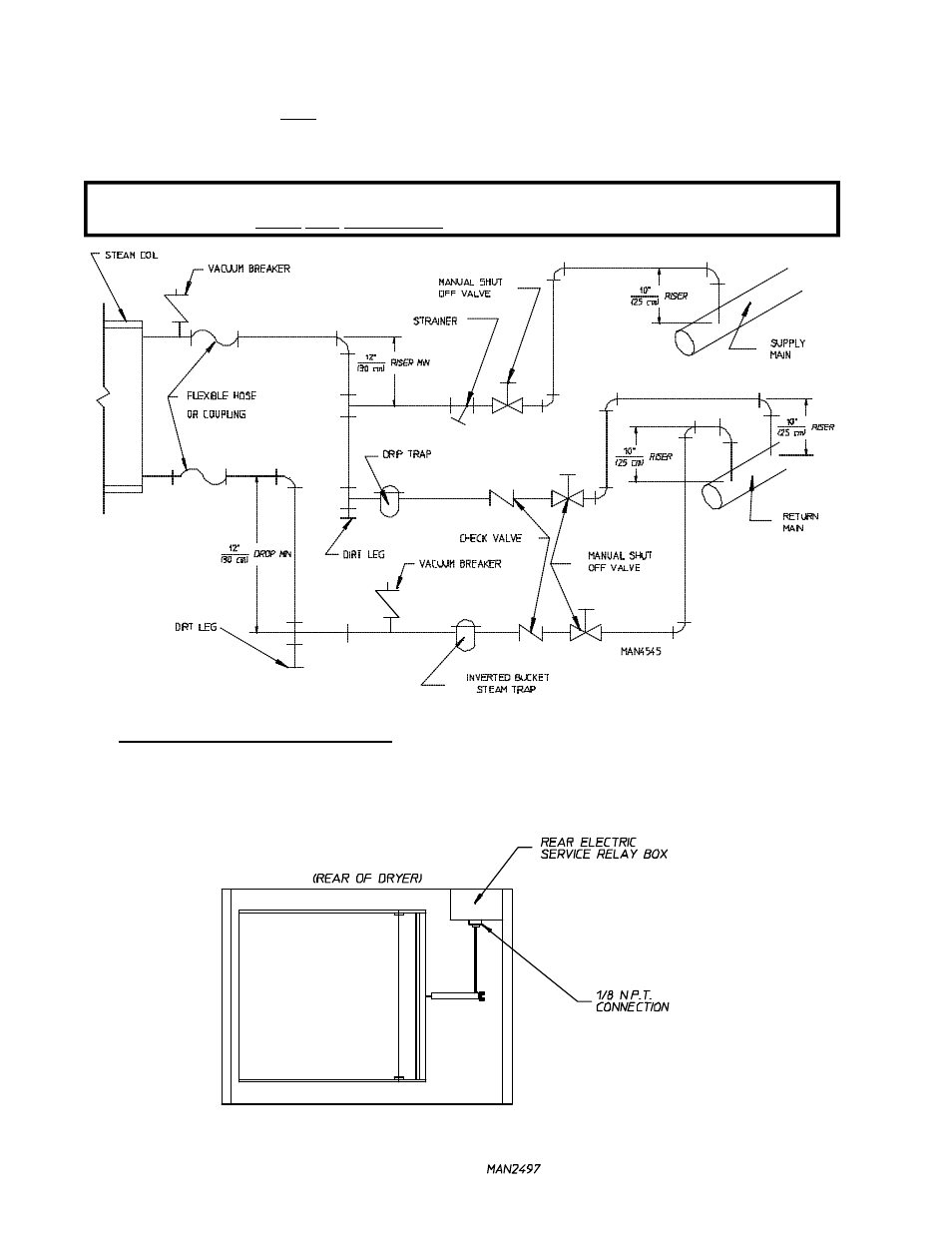

g. Water pockets in the supply line, caused by low points, will provide wet steam to the coil possibly causing

steam coil damage. ALL horizontal runs of steam supply piping should be pitched 1/4-inch (6.35 mm)

for every 1 foot (0.31 meters) back towards the steam supply header causing the condensate in the line

to drain to the header. Install a bypass trap in any low point to eliminate wet steam.

IMPORTANT: Flexible hose/coupling must be used. Coil failure due to hard plumbing connections

will VOID THE WARRANTY.

4. Steam Damper Air System Connections

The MLS-75 is manufactured with a pneumatic (piston) damper system, which requires an external supply

of compressed air. The air connection is made to the steam damper solenoid valve, which is located at the

rear inner top area of the dryer just in front of the electric service relay box.

- SL2929 (8 pages)

- AD-15 Phase 7 (31 pages)

- ML-75DIII (65 pages)

- AD-236 (33 pages)

- AD-50V (61 pages)

- ML-96HS (38 pages)

- 75 lb (6 pages)

- SL2020 (8 pages)

- AD-758DV (52 pages)

- Aquatex AD-76 (36 pages)

- MDG-75 (66 pages)

- MLG-130DR (HSI) (45 pages)

- MLG31PCB (44 pages)

- AD-410 (72 pages)

- AD-75THS (49 pages)

- Direct Spark Ignition ADG-530DSi II (33 pages)

- MLG32PD3 (39 pages)

- ML-55 (52 pages)

- ML-96 (34 pages)

- ADG-410 (75 pages)

- ADG-320D (53 pages)

- Phase 7 Gas/Steam AD-464 (62 pages)

- AD-120ES (50 pages)

- Gas/Electric/Steam ML-55HS (56 pages)

- AD-840 (47 pages)

- MDG31 (26 pages)

- D20 (37 pages)

- Aquatex AD-52 (37 pages)

- Phase 7 D30 (39 pages)

- 30 lb. Stacked Models (26 pages)

- ADH-120 (46 pages)

- ML-96D (43 pages)

- Super AD-50 (54 pages)

- ML-122 (52 pages)

- SL31 (12 pages)

- Super AD-30 (63 pages)

- MDG30V (52 pages)

- AD-670 (60 pages)

- SL31AD-15 (72 pages)

- ADS-464 II (80 pages)

- ML-190 (42 pages)

- Heat Reclaimer AD-170HR (20 pages)

- 50 lb. Single Pocket MDG50V (52 pages)

- 24 VAC Phase 5 AD-330 (40 pages)

- D75 (42 pages)