Operating steam pressure – American Dryer Corp. ML-75DII User Manual

Page 35

31

IMPORTANT: Coil failure due to improper PH level will VOID THE WARRANTY.

2. Steam Requirements - High Pressure

Inlet -------- 1-inch supply line connection -- qty. one (1) at top manifold.

Return ----- 1-inch return line connection -- qty. one (1) at top manifold.

3. Installation Instructions

To insure an adequate supply of steam is provided, be sure that the steam lines and steam return lines are

sized and laid out as stipulated in this manual. Inadequate steam lines and steam return lines or improper

steam plumbing will result in poor performance and can cause component failure. Clean, dry steam must

be provided to the dryer.

IMPORTANT: Steam coil failure due to water hammer by wet steam will VOID THE WARRANTY.

a. The pressure of the condensate in the steam supply will cause water hammer and subsequent heat

exchanger (steam coil) failure. The steam supply connection into the main supply line must be made

with a minimum 10-inch (25.4 cm) riser. This will prevent any condensate from draining towards the

dryer.

b. The steam supply piping to the dryer must include a 12-inch (30.48 cm) rise along with a drip trap and

check valve. This will prevent any condensate from entering the steam coil.

c. Flexible hoses or couplings must be used. The dryer vibrates slightly when it runs and this will cause

the steam coil connections to crack if they are hard piped to the supply and return mains.

d. Shutoff valves for each dryer should be installed in the supply line, return line, and drip trap return line.

This will allow the dryer to be isolated from the supply main and the return main if the dryer needs

maintenance work.

e. Install an inverted bucket steam trap and check valve at least 12-inches (30.48 cm) below the steam coil

as close to the coil as possible.

1) A trap with capacity of 700 pounds (317.51 kg) of condensate per hour at 125 PSI (8.62 bars) is

needed for each unit.

f. The supply line and the return line should be insulated. This will save energy and provide for the safety

of the operator and maintenance personnel.

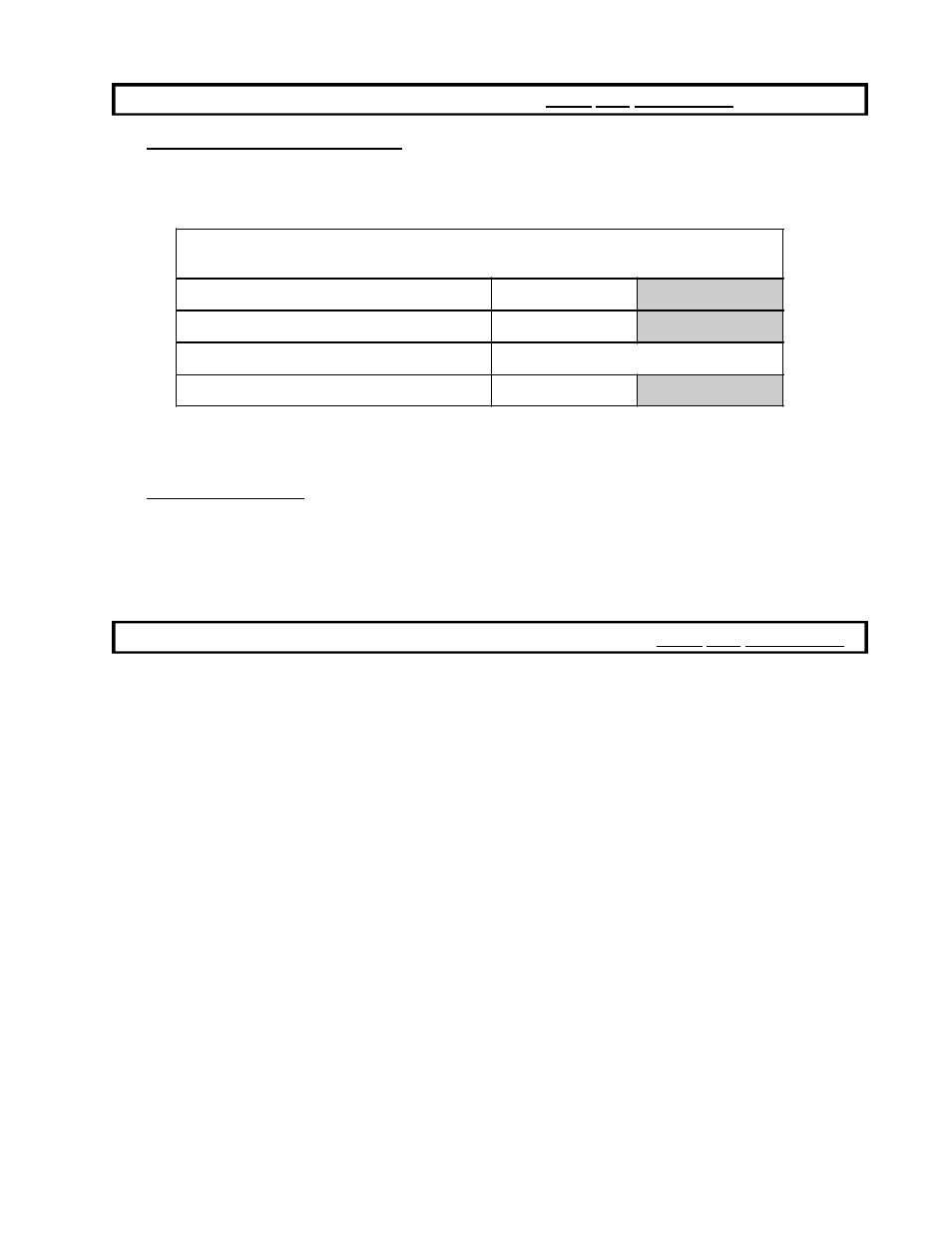

OPERATING STEAM PRESSURE

MAXIMUM

125 psig

862 kPa

MINIMUM

100 psig*

689 kPa

HEAT INPUT (NORMAL LOAD)

7

Bhp

CONSUMPTION (APPROXIMATE) @ 125 PSI

238.7

lbs/hr

108.3 kg/hr

Shaded areas are stated in metric equivalents

* Minimum operating pressure for optimum results.