Campbell Scientific PVS4100/4120/4150 Portable Automatic Samplers User Manual

Page 75

Section 5. Programming

5-35

attempts being made to obtain the failed

sample, will wait until the next sample

initiation.

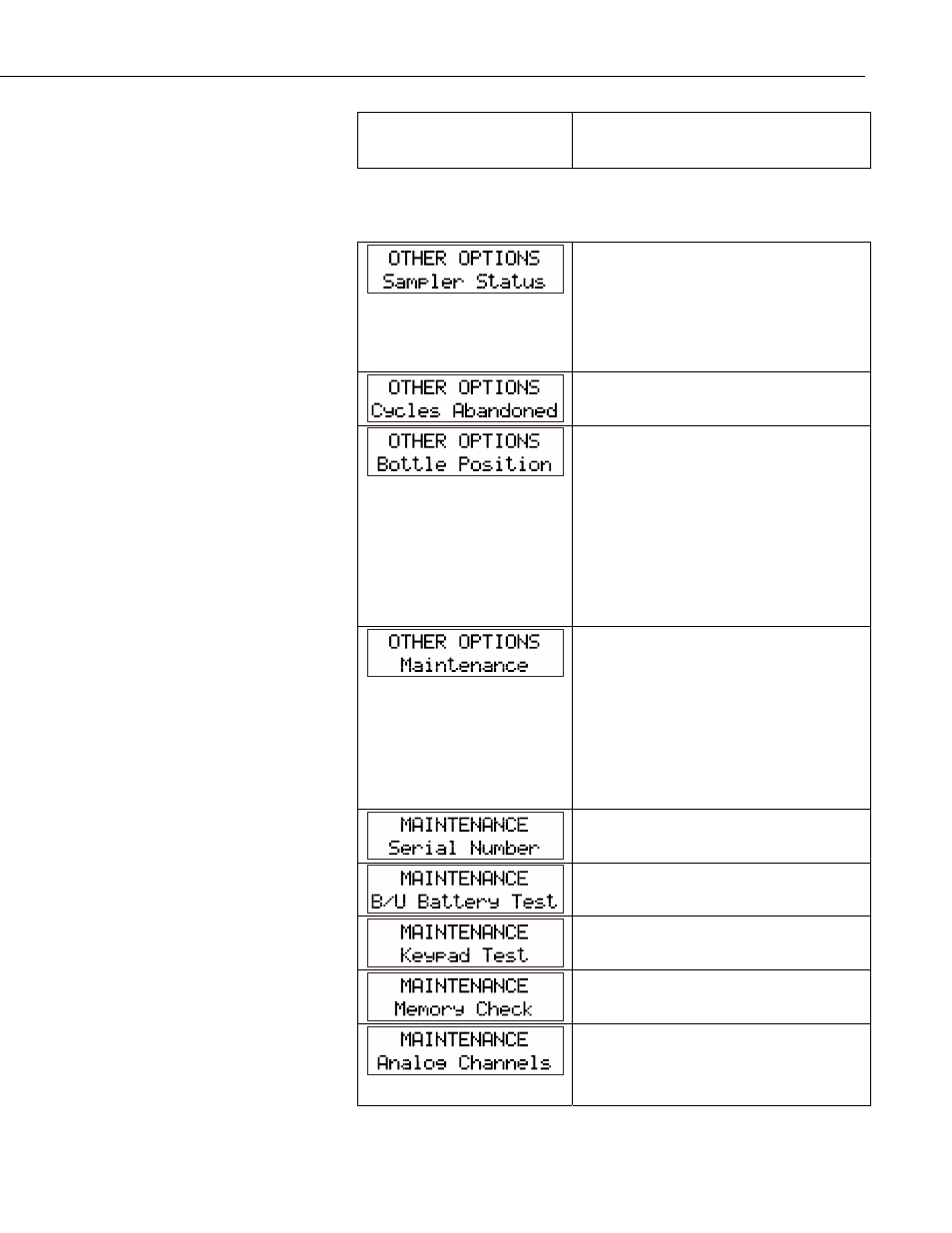

VIEW ONLY

The controller will remember conditions

encountered during normal operation.

Reasons for premature ending of a set

program will also be saved in memory. By

VIEWing this feature, this information can

be obtained at the time the sampler is

checked.

Values retained by the controller to indicate

number of missed samples.

When equipped with the appropriate

hardware and with the controller running the

proper program (i.e. Multi-Composite), the

current position of the distributor arm can be

determined by VIEWing this option. The

position information is relative to the

original position of the arm at the beginning

of the program start. Note: There is no

physical “Bottle 1”, any bottle can be

determined to be #1 at the beginning of a

sample program.

The following selections are all available

under the maintenance heading and are all

for VIEWing only. To check any of these

values or perform any tests, press VIEW,

then OTHER OPTIONS. Arrow left or

right as required until the flashing text

MAINTENANCE appears and press ENTER.

Once more, arrow left or right until the

desired flashing text appears, and press

ENTER.

Displays the microprocessor’s serial number.

Tests the controller’s on-board lithium

battery.

Tests the touchpad keys.

Checks the main IC’s read / write integrity.

Technicians Only! Digital Feedback from

two on-board A/D channels.

Channel 1: 4-20mA Input

Channel 2: Displays Float Voltage