Components and description – Wagner Power Tex User Manual

Page 3

3

English

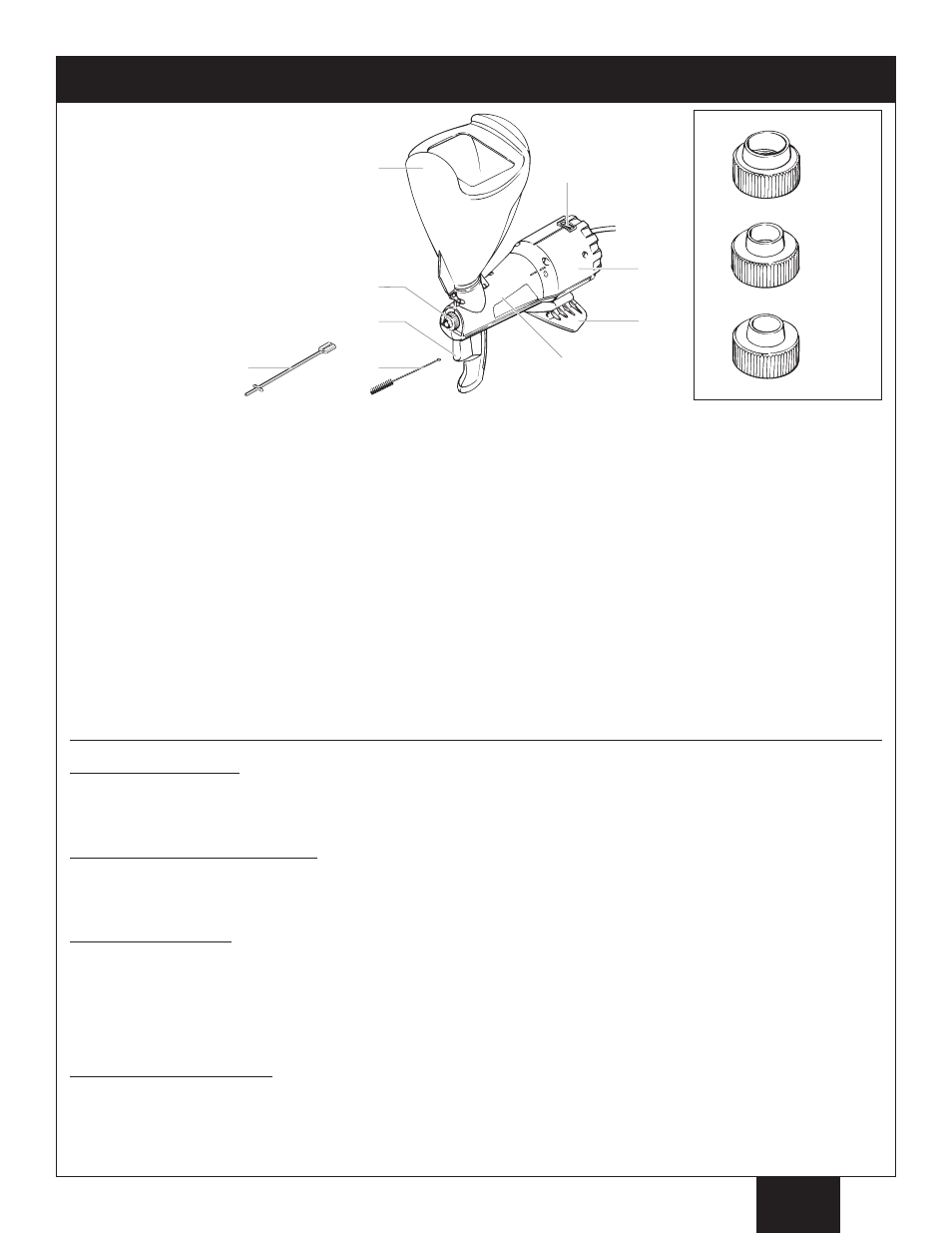

Components and Description

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

a)

ON / OFF switch

b)

Turbine

c)

Arm rest / Stand

d)

Sprayer body

e)

Hopper

f)

Spray nozzle

1) large nozzle

2) medium nozzle

3) small nozzle

g)

Trigger

h)

Cleaning brush

i)

Nozzle holder

Product Description:

The Power Tex

®

is intended for use for the residential application of water-based textured materials to ceilings, walls, or other

surfaces. The Power Tex

®

is an ideal tool for applying textured material to small areas or for repairing damaged sections of

knockdown or acoustic texture surfaces.

Materials that can be sprayed:

This unit has been designed to be used with

1) aggregated materials such as simulated acoustic (“popcorn”) and 2) unaggregated

materials such as diluted joint compound for knockdown and orange peel. Make sure to follow all the manufacturer’s

recommendations and warnings when mixing and using textured materials.

Mixing the material:

When mixing the material you are going to spray, follow the manufacturer’s directions.

It is very important that the material

you use is properly mixed. The material should appear creamy, wet, and lump-free, similiar to pancake batter (refer to chart on

page 5 for variations).

DO NOT mix the material inside the hopper. Use a separate container to mix the material. For best

results, use an electric drill with a paint-mixer attachment when mixing the material. Make sure the material settles for 15 minutes

before using and then mix again thoroughly. To ensure proper consistency, mix enough material to complete the job. Mixing

separate batches for one job may give inconsistent results.

Preparing the work area:

Texture spraying creates a great deal of dust and overspray material. It is necessary that you cover with drop cloths anything you

do not want sprayed (walls, windows, floors, furniture) and remove as many non-essential items from the room as possible. Make

sure the work surface has also been properly prepared. Application over unsealed, stained, improperly prepared, or not

completely dry surfaces may cause discoloration and adhesion problems.

ON/OFF Switch. . . . . . . . . . . The ON/OFF switch turns the power to the sprayer on and off (O=OFF, l=ON).

Turbine . . . . . . . . . . . . . . . . . The turbine provides air flow that delivers the material from the sprayer.

Lock N Go™ . . . . . . . . . . . . This sprayer has been designed with Lock N Go™ technology, allowing for easy cleanup.

Trigger. . . . . . . . . . . . . . . . . . The trigger controls the delivery of the fluid being pumped. The farther the trigger is pulled, the

more material will flow from the nozzle.

DO NOT pull the trigger while the turbine is turned OFF (l)

and if there is material in the hopper. This may cause material to flow into the turbine.

Spray nozzle. . . . . . . . . . . . . This unit is equipped with three different spray nozzles. The nozzles have different opening sizes

(large, medium, small) that determine the volume of material being sprayed. The bigger the

opening, the more material will flow from the nozzle.

Hopper . . . . . . . . . . . . . . . . . The hopper can rotate 180º to accomodate a higher spraying angle. The user’s free hand may also

be placed on the rear of the hopper for increased stability during usage.

Arm rest . . . . . . . . . . . . . . . . The sprayer has been designed to rest comfortably on the user’s arm during usage.

Nozzle holder . . . . . . . . . . . . The nozzle holder can be threaded through the nozzles and then wrapped around the power cord

for easy stoage.

1)

2)

3)

white

(large)

yellow

(medium)

black

(small)