Setup, Material preparation, Fill container – Wagner Control Spray User Manual

Page 4: Assembly, Aligning the suction tube

4

English

Setup

Material Preparation

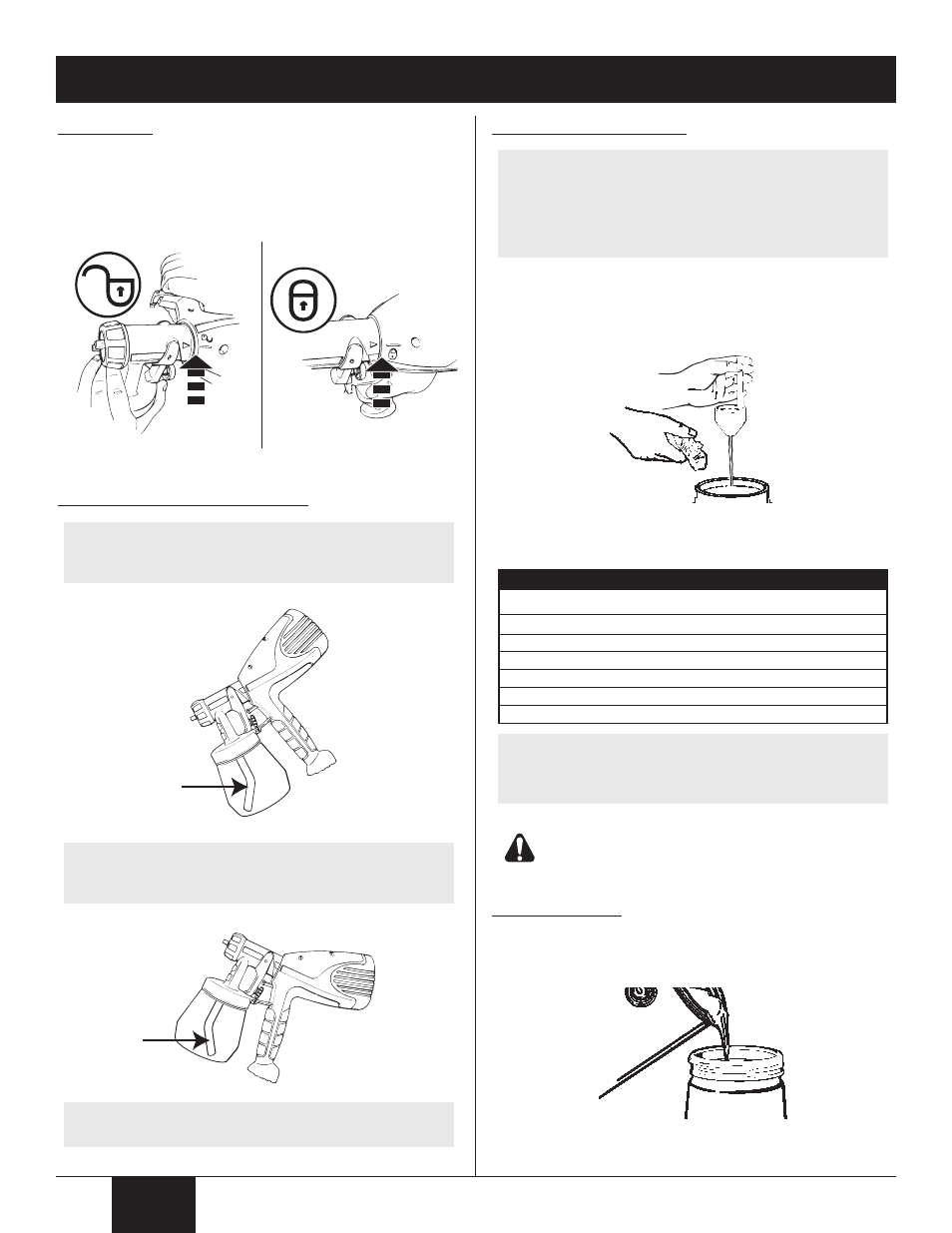

1. Stir the spraying material thoroughly before measuring

viscosity.

2. Dip the viscosity test cup completely into the spraying

material.

3. Hold the test cup up and measure the time in seconds until

the liquid empties out. This time is referred to below as

Runout Time.

MATERIAL FLASH POINT MUST BE 70°F (21°C) OR

HIGHER.

Fill Container

1. Unscrew the cup from the spray gun.

2. After the material has been properly thinned and strained,

fill the container to the top of the neck.

3. Carefully screw the cup back onto the spray gun.

Material to be sprayed should always be strained to

remove any impurities in the paint which may enter and

clog the system. Impurities in the paint will give poor

performance and a poor finish.

Thinning Chart

Material

Runout Time

1) Oil enamel

2) Oil based primer

3) Oil stain

4) Clear sealer

5) Polyurethane

6) Varnish

25-40

30-45

No thinning required

No thinning required

No thinning required

20-50

Before spraying, the material being used may need to be

thinned with the proper solvent as specified by the

material manufacturer. Never exceed the thinning

advice given by the coating manufacturer.

Do not use materials with a flashpoint below 70°F

(21°C). Follow the instructions below.

Assembly

1. Align the arrow on the spray gun with the “unlock” symbol

on the turbine.

2. Insert and twist the spray gun into the turbine toward the

“lock” symbol on the turbine. The tab below the trigger will

lock the two pieces into place.

Aligning the Suction Tube

By pointing the suction tube in the proper direction, you

will not have to refill the container as often.

If you are going to be spraying in an upward direction,

the angled end of the suction tube should be pointing

toward the rear of the gun.

If you are going to be spraying in a downward direction,

the angled end of the suction tube should be pointing

toward the front of the gun.