Part 1 installation, V piping – Midco J83-DS User Manual

Page 3

Part 1 Installation

Part 1

Installation

Continued

IV Chimney, Vent

Connector *

and Draft Control

*Formerly referred

to as Flue Pipe

3

To change the Mounting Flange to its alternate position, horizontal or 10° down firing, remove

the four (4) screws that attach it to the burner, rotate the flange 180° and reinstall the screws.

Before mounting the burner, check that the Blast Tube and Blower Housing are clear of foreign

material and that the Main Gas Port and Nozzle Support is clean and undamaged.

If the incinerator is located outdoors, the burner and all of its components, except the Main

Manual Shut-Off Valve, must be protected from weather. The Midco

®

Accessory Weatherhood will

provide such protection.

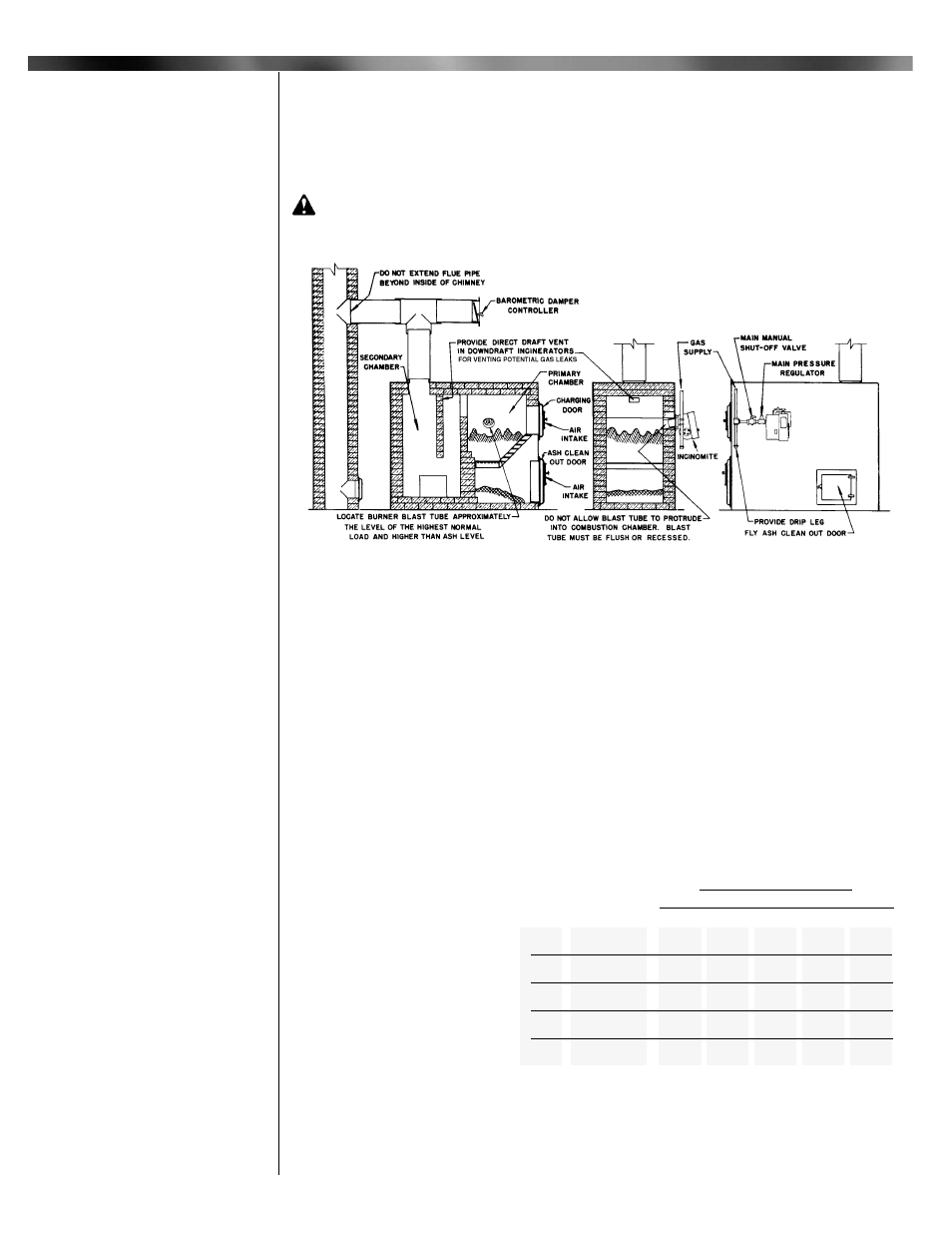

CAUTION: If the incinerator is of the down draft design, make sure that a direct draft

vent opening of approximately 10 square inches has been put through the top of the drop

section(s) to provide for the venting of any gas leakage. See Figure 1.

_________________________________

The size and type of material used for the vent connector and chimney must conform to the rec-

ommendations of the incinerator manufacturer, as well as local and national codes. This is espe-

cially true where high flue gas temperatures are encountered.

When natural draft is used and the chimney height is over 25 feet, a barometric damper of the

same size as the vent connector should be installed. If the chimney is high enough to make it dif-

ficult for the barometric to maintain a maximum incineration chamber over-fire draft, 0 to minus

0.5" W.C., a fixed damper should be installed in the vent connector between the barometric and

chimney to restrict the chimney draft to a point within the controlling capacity of the barometric.

After final setting, the damper should be permanently fastened into position per ANSI Z223.1-lat-

est edition "National Fuel Gas Code", or latest edition available from American National

Standards Institute to prevent tampering.

_________________________________

The supply piping to the burner should branch off from the main line as close to the source as

possible (NATURAL gas meter or

PROPANE tank regulator). When

branching off from an existing gas

line, do not tap o ff the bottom of a

horizontal section. Use new black

pipe and malleable fittings free

from cutting and threading burrs or

defects.

Use pipe joint compound resist-

ant to liquid petroleum gases

when using either NATURAL or

PROPANE gas. Piping must com-

ply with the local and national

codes. If the burner piping must be

rearranged because of space limi-

tations, be sure to carry out the

general configuration shown in

Figure 2.

Figure 1: Typical Installation

V Piping

Capacities shown are for total pressure drop of 0.3”W.C. For

higher permissible pressure drops consult your fuel supplier.

Source: Gas Engineers Handbook-1974

Industrial Press Inc. NY, NY

Table 1: Supply Pipe Capacities in MBH

Type

of

Gas

NATURAL

PROPANE

NATURAL

PROPANE

NATURAL

PROPANE

NATURAL

PROPANE

NATURAL

PROPANE

10

275

450

520

800

800

-

-

-

-

-

20

200

300

350

550

730

800

800

-

-

-

40

130

200

245

385

500

790

760

800

800

-

60

100

165

195

300

400

630

610

800

800

-

100

-

125

150

235

300

480

460

725

800

800

NPT

Pipe

Size

3/4"

1"

1-1/4"

1-1/2"

2

Approximate Capacity - MBH

Length of Pipe / Feet