Xi redundant combination gas valve, Xii s8680j electronic control, Xiii special equipment (oem versions) – Midco 400B-33 User Manual

Page 8

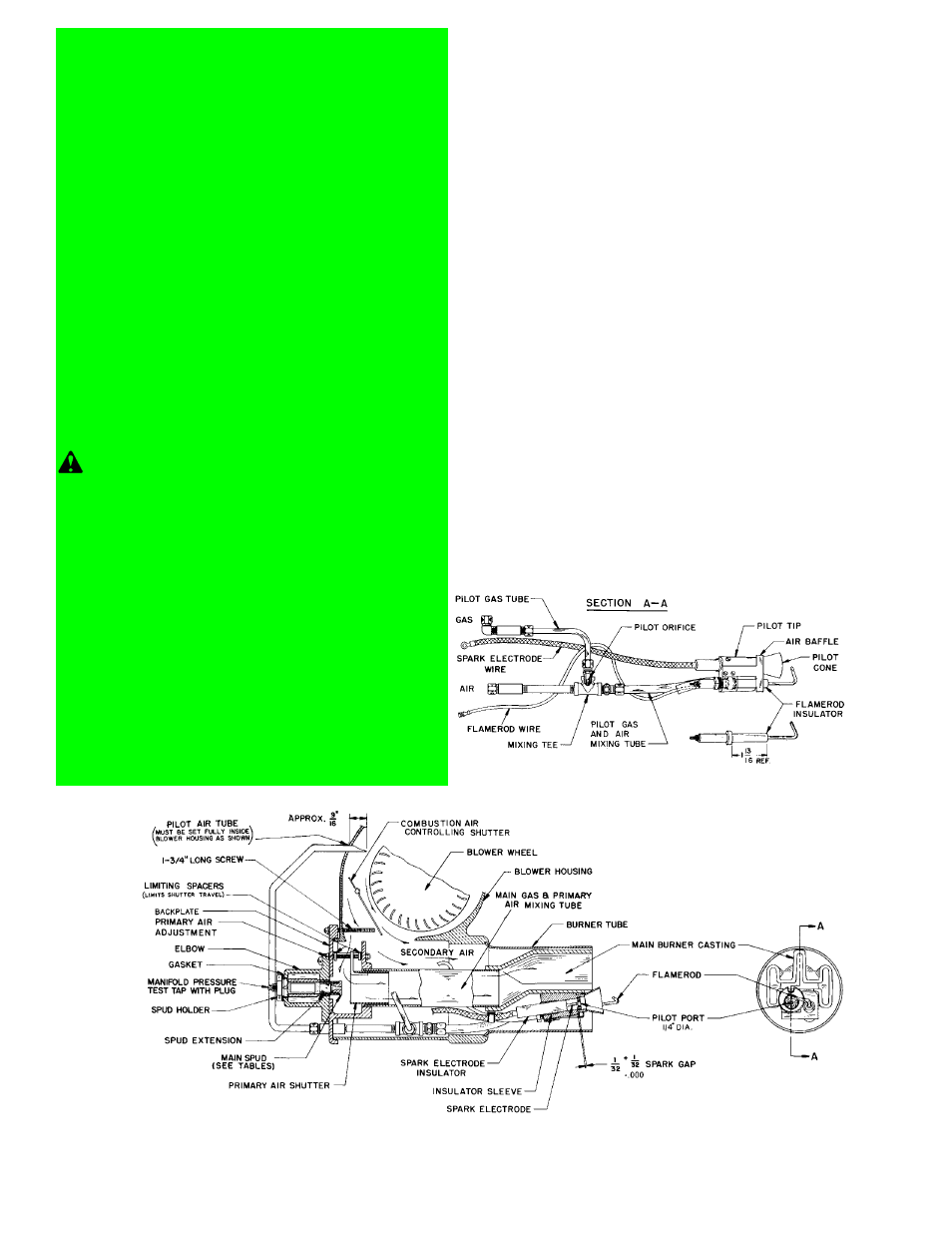

FIGURE 7 General Assembly

-8-

XI REDUNDANT COMBINATION GAS

VALVE

The 24 volt Combination Valve serves three functions:

1.) Manual Gas Shut-Off, 2.) Manifold gas pressure

regulation, 3.) Automatic electric redundant (double

seated) gas valve.

■

■

For manual control the Manual Gas Cock Knob is

turned full ON or full OFF. The dial has to be depressed

to be turned in one direction, but it depends on the make

of the valve whether it is to the ON or OFF position.

■

■

The Main Gas Pressure Regulator, which has an outlet

pressure setting range of approximately 2.0" to 4.0"

W.C., is factory set for a manifold gas pressure of 3.5"

W.C. for NATURAL. If pressure adjustment is required

for setting capacity, remove regulator cap for access to

slotted adjustment screw. Turning of adjustment screw

counter-clockwise reduces pressure; clockwise

increases pressure.Do not adjust past the point where no

change in pressure is noted.

NOTE: Pressure setting must be made with burner

running and main gas ON.

CAUTION: When adjusting the regulator, if gas

supply pressure is below its specified range, an

overfire condition could result as pressure returns to

normal, particularly if the regulator adjustment

screw is bottomed out.

ALWAYS confirm that at least the minimum rated gas

pressure is being supplied to the burner during regulator

adjustments, and NEVER bottom out regulator screw.

■

■

To set to low outlet pressure for initial start-up, turn the

adjusting screw counter-clockwise 2.5 turns to raise it to

about 1/4" below the top.

■

■

The tap for manifold gas pressure measurement is

located in the burner spud holder (see Figure 7).

Remove plug for access.

■

■

If the Main Gas Pressure Regulator fails to maintain a

constant manifold gas pressure within ±0.1" W.C., and it

is confirmed that the inlet gas pressure to the

combination valve is 14.0" W.C. maximum during

standby, and 5.0" W.C. minimum for NATURAL gas

(11.0" W.C. for PROPANE gas), with the main flame on,

the regulator portion of the valve is defective and the

entire valve must be replaced.

■

■

If, on a call for heat, flame ignition does not occur, refer

to the TROUBLE CHART for further information.

■

■

If leakage through the valve occurs, as evidenced by

the presence of flame on standby, the entire valve must

be replaced.

■

■

If the Combination Valve has been moved or replaced,

soap bubble test for leaks with the burner running.

XII S8680J ELECTRONIC CONTROL

■

■

For operation characteristics refer to Honeywell

Control literature provided with burner.

XIII

SPECIAL EQUIPMENT (OEM

VERSIONS)

Special equipment, either factory or contractor

installed, may cause variation in the procedures and

descriptions given in this manual.

Consult the OEM's manual to identify the differences in

the information.