Vii main gas spud selection – Midco F400-33 User Manual

Page 5

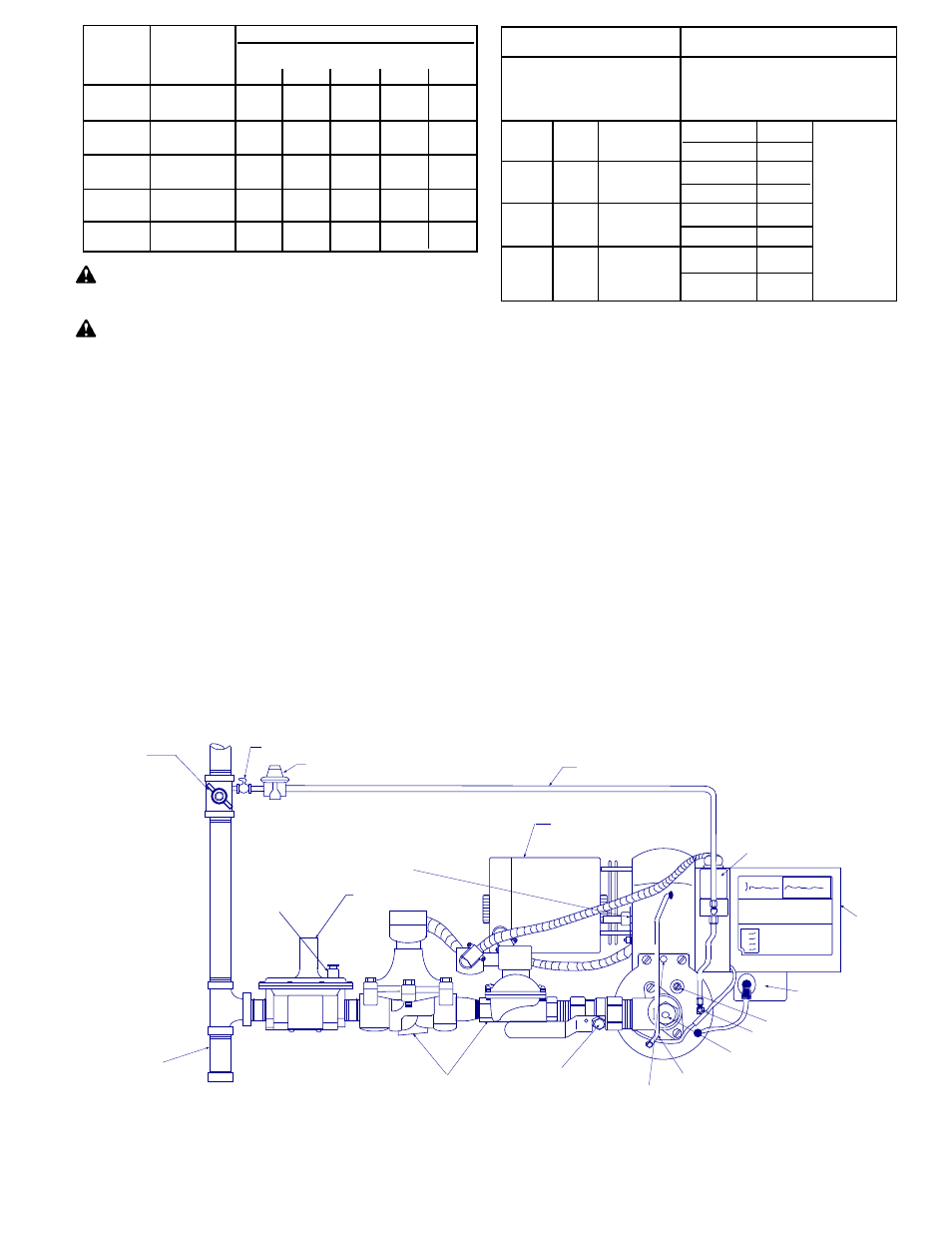

SPUD

DRILL

SIZE

#21(.159)

#15(.180)

#9(.196)

#3(.213)

#1(.228)

17/64(.265)

9/32(.281)

19/64(.296)

BURNER

INPUT

MBH

1

185

300

300

400

400

540

540

700

SPUD

DRILL

SIZE

11/32

(.343)

25/64

(.390)

7/16

3

(.437)

SPUD

RE-

MOVED

DRIP

LEG

PILOT TUBING

MANUAL PILOT VALVE

PILOT REGULATOR

MAIN AIR

CONTROLLING SHUTTER

(COUNTER CLOCKWISE

TO OPEN)

BLOWER MOTOR

MAIN AND

REDUNDANT MAIN

GAS VALVES

BALL VALVE

TEST COCK

"PEEP" SIGHT

PILOT AND AIR TUBE

MAIN TEST TAP

PILOT TEST TAP

PRIMARY AIR ADJUSTMENT

SPARK GENERATOR

FLAME

SAFEGUARD

CONTROL

PILOT SOLENOID

MAIN

REGULATOR

MAIN REGULATOR

VENT

MANUAL

BALL VALVE

10

275

400

500

700

700

TYPE

OF

GAS

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

Natural

APPROXIMATE CAPACITY-MBH

LENGTH OF PIPE

100

225

300

475

450

700

700

PIPE

SIZE

3Ú4

(400-33 only)

1

1

1

Ъ

4

1

1

Ъ

2

2

20

300

350

550

700

700

40

200

250

375

500

700

700

60

200

300

400

625

600

700

700

-5-

FIGURE 5

Piping Connections

MANIFOLD

PRESSURE

W.C.

2

10.0"

MANIFOLD

PRESSURE

W.C.

2

1.5"

3.5"

2.0"

3.5"

2.0"

4.0"

1.85"

3.2"

NATURAL GAS

BURNER

INPUT

MBH

1

185

250

300

350

400

540

625

700

PROPANE GAS

CAUTION: Purge outside the building. Do not

purge into the gas utilization equipment combustion

chamber.

CAUTION: Do not exceed maximum or minimum

rated capacity of burner model as shown in Table 1.

Capacities shown are for a total pressure drop of

0.3"W.C. For 0.5"W.C. pressure drop, multiply capacity

shown by 1.3 For higher permissible pressure drops,

consult your utility.

TABLE 2: Schedule 40 NPT Pipe-Capacity Chart

VII

MAIN GAS SPUD SELECTION

Burners are approved for use with NATURAL or

PROPANE gas and should be used only with the gas

specified on the rating plate.

■

The gas input should be set at the heating rate

determined by the building heat loss and/or heating plant

survey, but not exceeding the rated maximum input of

the gas utilization equipment or Economite burner.

■

Burners are shipped equipped for NATURAL gas; the

model 400 with a 11/32 drill spud installed, and the F400

with the spud removed. Compare the gas input required

with the spud capacities shown in the spud table and, if

necessary, install the spare spud (see Figure 7).

DATA IS APPROXIMATE AND BASED ON Ò0"

OVERFIRE PRESSURE AT SEA LEVEL

1.

Input range of spud. Adjust the main regulator to

vary the manifold gas pressure and burner input

within the range shown for a specific spud drill size.

With PROPANE, do not exceed 11.0"W.C. under

any circumstances.

2.

Approximate gas pressure at manifold gas pressure

tap.

3.

Drill out 25Ú64 spare spud to 7Ú16.

TABLE 3: Spud Capacity and Preliminary Gas Settings.