Cut 250, Routine and special maintenance – Dake Model Cut 250 User Manual

Page 8

8

CUT 250

CUT 250

CUT 250

CUT 250

CUT 250

ROUTINE

AND SPECIAL

MAINTENANCE

THE MAINTENANCE JOBS ARE LISTED BELOW, DIVIDED

INTO DAILY, WEEKLY, MONTHLY AND SIX-MONTHLY

INTERVALS. IF THE FOLLOWING OPERATIONS ARE

NEGLECTED, THE RESULT WILL BE PREMATURE WEAR

OF THE MACHINE AND POOR PERFORMANCE.

8.1 - Daily maintenance

- General cleaning of the machine to remove accumulated

shavings.

- Top up the level of lubricating coolant.

- Check the disk for wear.

- Lift the head into a high position to avoid yield stress on the

return spring.

- Check functionality of the shields and emergency stops.

1

8

8.3 - Monthly maintenance

- Check tightness of the screws on the motor, the pump, the

jaws and shields.

- Check that the shields are unbroken.

- Grease the head hinge pin.

8.4 - Six-monthly maintenance

- Change the oil in the reduction unit using oil type GEARCO

85W-140 by NATIONAL CHEMSERACH or MOBIL GLYCOLE

30 or KLUBER SINTHESO 460 EP or an equivalent oil,

proceeding as follows:

1

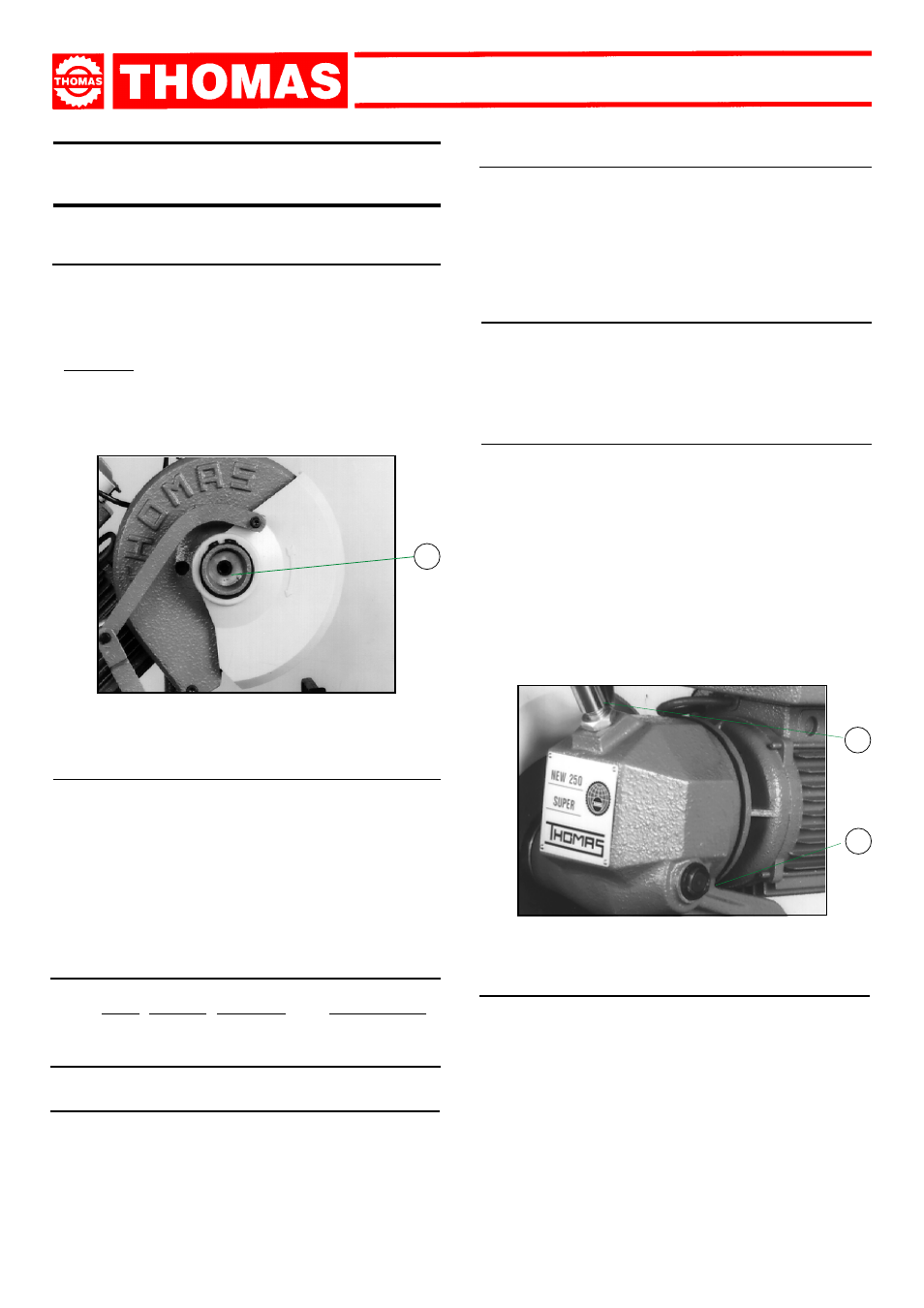

- Remove the connecting plug from the electric box and un-

screw the head moving lever.

- Drain off the old oil from the cap at the side ( 1 ).

- Pour in new oil up to the mark ( 1 ), through the lever fixing

hole, keeping the head in a horizontal position ( 2 ).

- Reassemble all the parts.

- Check continuity of the equipotential protection circuit.

8.5 - Oils for lubricating coolant

Considering the vast range of products on the market, the user

can choose the one most suited to his own requirements, using

as reference the type SHELL LUTEM OIL ECO.

THE MINIMUM PERCENTAGE OF OIL DILUTED IN WATER

IS 8 - 10 %.

BEFORE PERFORMING THE FOLLOWING OPERATIONS,

THE ELECTRIC POWER SUPPLY AND THE POWER CABLE

MUST BE COMPLETELY DISCONNECTED.

7.4 - Changing the disk

To change the disk:

- Release the mobile yellow, white or orange guard and turn it back.

- Block a piece of wood in the vice and lean the disk on it.

- Insert the special spanner provided and remove the screw

( 1 ), slackening it in a clockwise direction because it has a

left-handed thread, then slip off the flange that holds the disk.

- Fit the new disk, checking the cutting direction of the teeth,

then replace the flange, the screw and the mobile white, yellow

or orange guard.

7.5 - Changing the lubricating coolant pump

- Takes yhe pipes of the lubricating-refrigerating system off.

- Remove the fastening screws and replace the little pump,

being careful to keep the driving stem centred on the drive

shaft bearing.

2

8.2 - Weekly maintenance

- More accurate general cleaning of the machine to remove

shavings, especially from the lubricant fluid tank.

- Clean the filter of the pump suction head and the suction

area.

- Clean and grease the screw and the sliding guide of the vice.

- Clean the disk housing.

- Sharpen the disk teeth.