Zip 30 - mul – Dake Model Zip 30 User Manual

Page 14

14

ZIP 30 - MUL

ZIP 30 - MUL

ZIP 30 - MUL

ZIP 30 - MUL

ZIP 30 - MULTI MODE

TI MODE

TI MODE

TI MODE

TI MODE

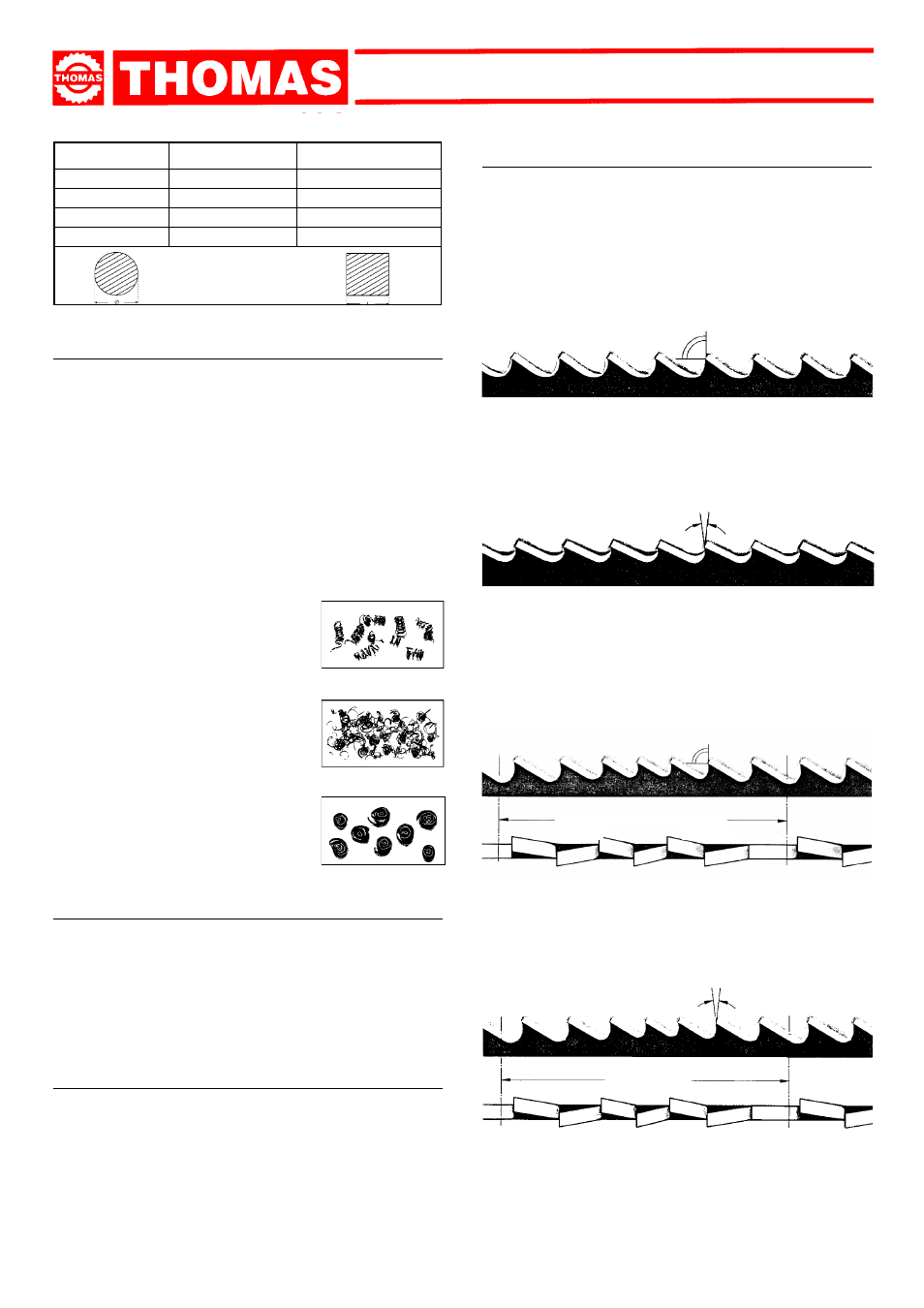

9.7 - Blade type

They differ essentially in their constructive characteristics, such

as:

- shape and cutting angle of tooth

- pitch

- set

Shape and angle of tooth

REGULAR TOOTH: 0° rake and constant pitch.

Most common form for transversal or inclined cutting of solid

small and average cross-sections or pipes, in laminated mild

steel and grey iron or general metal.

POSITIVE RAKE TOOTH: 9° - 10° positive rake and constant

pitch.

positive

Particular use for crosswise or inclined cuts in solid sections or

large pipes, but above all harder materials (highly alloyed and

stainless steels, special bronze and forge pig).

COMBO TOOTH: pitch varies between teeth and consequently

varying teeth size and varying gullet depths. Pitch varies be-

tween teeth which ensures a smoother, quieter cut and longer

blade life owing to the lack of vibration.

SOLID Ø OR L MM

Z CONTINUOUS

TOOTH DESIGN

Z COMBO

TOOTH DESIGN

TILL 30

8

5/8

FROM 30 TO 60

6

4/6

FROM 40 TO 80

4

4/6

MORE THAN 90

3

3/4

Ø = DIAMETER L = WIDTH

9.4 - Cutting and advance speed

The cutting speed (m/min) and the advance speed (cm

2

/min =

area travelled by the disk teeth when removing shavings) are

limited by the development of heat close to the tips of the teeth.

- The cutting speed is subordinate to the resistance of the ma-

terial (R = N/mm

2

), to its hardness (HRC) and to the dimen-

sions of the widest section.

- Too high an advance speed (= lowering of the saw frame)

tends to cause the disk to deviate from the ideal cutting path,

producing non rectilinear cuts on both the vertical and the

horizontal plane.

The best combination of these two parameters can be seen

directly examining the chips.

Long spiral-shaped chips indicate ideal

cutting.

Very fine or pulverized chips indicate lack

of feed and/or cutting pressure.

Thick and/or blue chips indicate overload

of the blade.

9.5 - Blade running-in

When cutting for the first time, it is good practice to run in

the tool making a series of cuts at a low advance speed

(= 30-35 cm

2

/min on material of average dimensions with re-

spect to the cutting capacity and solid section of normal steel

with R = 410-510 N/mm

2

), generously spraying the cutting

area with lubricating coolant.

9.6 - Blade structure

Bi-metal blades are the most commonly used. They consist in a

silicon-steel blade backing with electron beam or laser welded

high speed steel (HHS) cutting edge. The type of stocks are

classified in M2, M42, M51 and differ from each other because

of their major hardness due to the increasing percentage of

Cobalt (Co) and molybdenum (Mo) contained in the metal alloy.

distance between teeth

Another advantage offered in the use of this type of blade in the

fact that with an only blade it is possible to cut a wide range of

different materials in size and type.

COMBO TOOTH: 9° - 10° positive rake.

positive

This type of blade is the most suitable for the cutting of section

bars and large and thick pipes as well as for the cutting of solid

bars at maximum machine capacity. Available pitches: 3-4/4-6.