Dake Model SE 912 User Manual

Page 15

- 15 -

are so far apart that they straddle the work, severe damage to the work piece and to the Made can

result.

CHANGING BLADE

Raise saw head to the highest position and open the blade guards. Loosen tension screw knob

sufficiently to allow the saw blade to slip off the wheels. Install the new blade with teeth slanting

toward the motor as follows:

(1). Place the blade in between each of the guide bearings.

(2). Slip the blade around the motor pulley (bottom) with the left hand and hold in position.

(3). Hold the blade taut against the motor pulley by pulling the blade upward with the right hand

Which is placed at the top of the Made?

(4). Remove left hand from. Bottom pulley and place is at the top aide of the Made to continue the

Application on the upward pull on the blade.

(5). Remove right hand from blade and adjust the position of the top pulley to permit left hand to

slip the blade around the pulley using the thumb, index and little finger as guides.

(6). Adjust the blade tension knob clockwise until it is just right enough so no blade slippage

occurs. Do not tighten excessively.

(7). Replace the blade guards.

(8). Place 2-3 drops of oil on the blade.

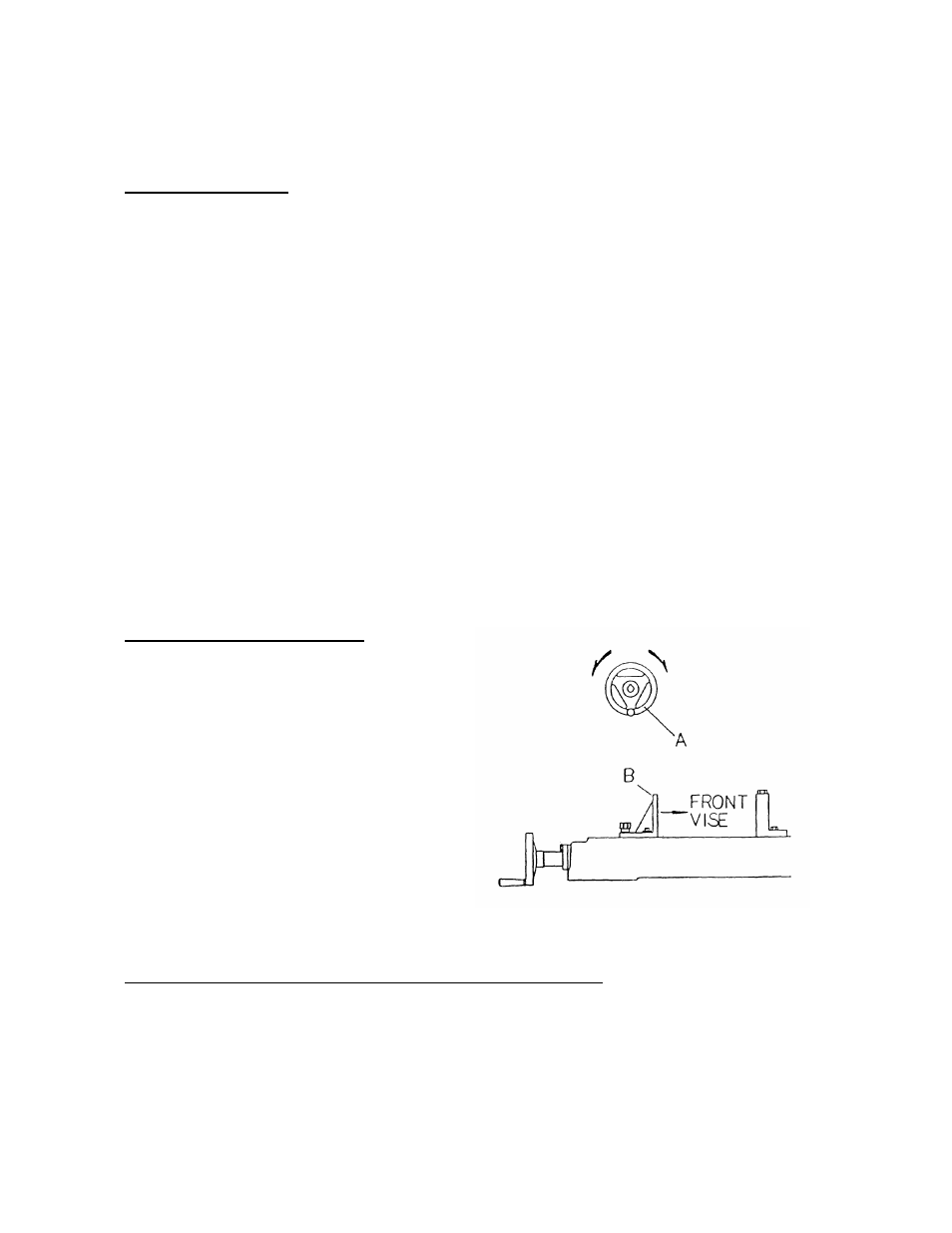

USAGE OF THE OUICK VISE

The work piece is placed between the vise

jaws with the amount to be cut-off

extending out past the blade. Your

machine is equipped with a "quick action"

vise jaw which allows you to instantly

position the moveable vise jaw (B).

Simply turn Handwheel (A)

counterclockwise 1/2 turn and move the

vise jaw (B) to the desired position. Then

tighten the vise jaw (B) against the

work-piece by turning hand-wheel clockwise.

QUICK VISE ADJUSTMENT FOR ANGLE CUT (912B.912G)

(1). Loosen the A. B. C. D. Screw.

(2). Adjust rear vise to the threaded hole position. (E)

(3). Set the scale to the desired angle.

(4). Adjust the front vise (F) to parallel the rear vise (E)

(5). Tighten the A. B. C. D. Screw.