Dake Model SE 912 User Manual

Page 10

- 10 -

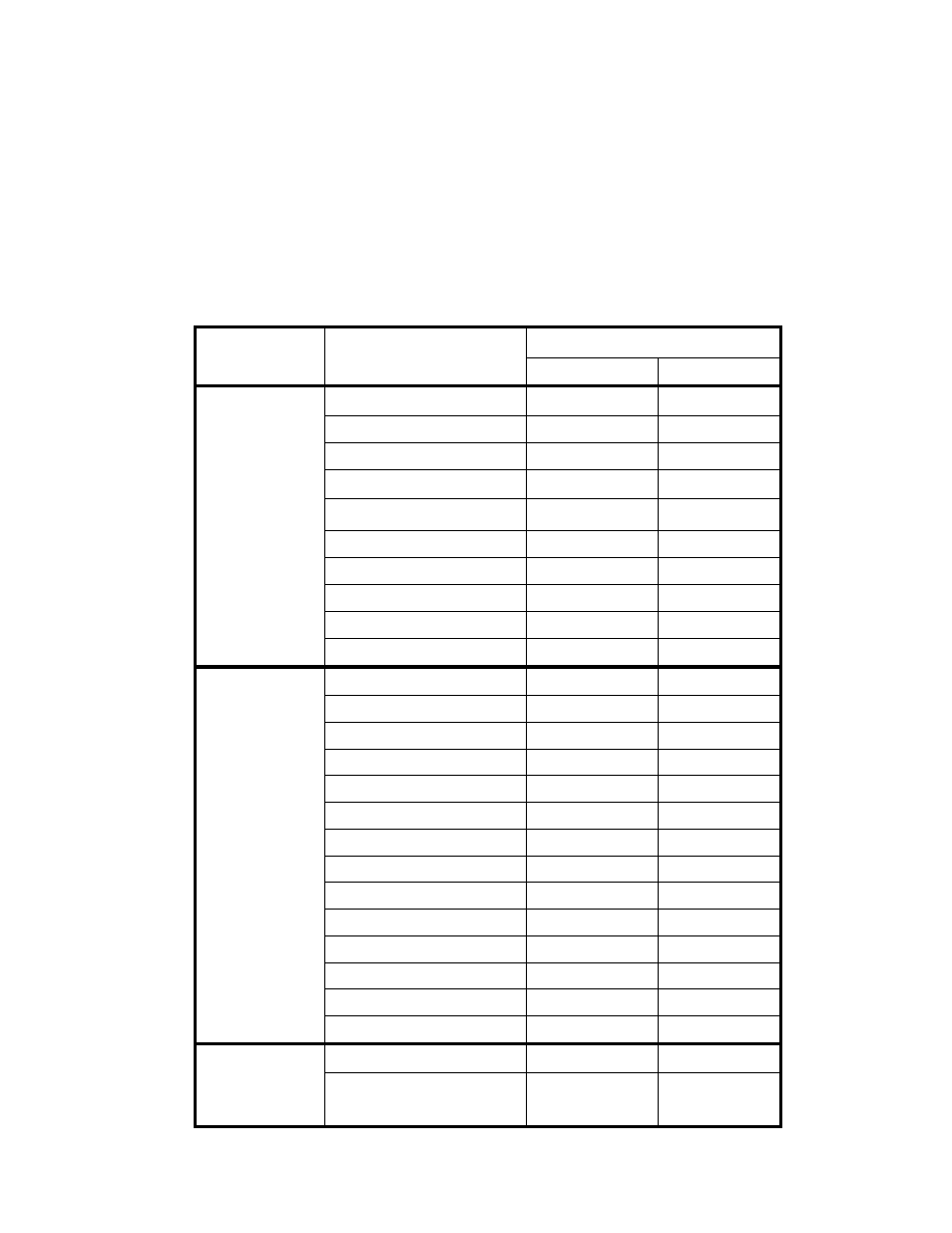

5. BI-METAL SPEEDS AND FEEDS

These figures are a guide to cutting 4"(100mm) material (with a 314 Vari-Tooth) when using a

cutting fluid.

Increase Band Speed: 15% When cutting 1/4"(6.4mm) material (l0/l4 Vari-Tooth)

12% When cutting 3/4"(19 mm) material (6/10 Vari-Tooth)

10% When cutting 1-1/4"(32 mm) material (5/8 Vari-Tooth)

5% When cutting 2-1/2" (64 mm) material (4/6 Vari-Tooth)

Decrease Band Speed: 12% When cutting 8"(200mm) material (2/3 Vari-Tooth)

BAND SPEED

MATERIAL

ALLOY

ASTM NO.

FT./MIN

M/MIN

173,932

314

96

330,365

284

87

623,624

264

81

230,260,272

244

74

280,264,632,655

244

74

101,102,110,122,172

234

71

1751,182,220,510

234

71

625,706,715,934

234

71

630

229

70

Copper

Alloy

811

214

65

1117

339

103

1137

289

88

1141,1144

279

85

1141 HI STRESS

279

85

1030

329

100

1008,1015,1020,1025

319

97

1035

309

94

1018,1021,1022

299

91

1026,1513

299

91

A36(SHAPES),1040

269

82

1042,1541

249

76

1044,1045

219

67

1060

199

61

Carbon

Steel

1095

184

56

8615,8620,8622

239

73

Ni-Cr-Mo

Alloy Steel

4340,E4340,8630

219

67