Field operation & adjustment, Mechanical field operation and adjustment – Summers Truck Supersprayer User Manual

Page 26

SECTION 3 - SPRAYER OPERATION

3.2

4. Install nozzle tip back onto sprayer.

f. During periods of use in freezing temperatures:

1. (Flush entire sprayer system with 100% RV antifreeze.) RV antifreeze is nontoxic

and safe for the environment. It must be used in 100 percent concentrations, but it

is more economical then permanent antifreeze to purchase and will not harm plastic

spray components. Read and follow antifreeze container instructions.

2. Spray solution through nozzles.

3. Allow dripless nozzles to drain by loosening each diaphragm check valve nut.

IMPORTANT!

LIQUID REMAINS IN THE 1 INCH WET BOOM EVEN WITH THE NOZZLE DIAPHRAGM

CHECK VALVES LOOSENED. WITH BOTH BOOMS IN TRANSPORT POSITION LIQUID AC-

CUMULATES NEAR THE BOOM PIVOT POINT. TO ALLOW DRAINAGE, REMOVE THE

BOOM END CAP OR END NOZZLE AND SUPPLY HOSE FROM EACH BOOM.

g. When changing chemicals, follow chemical manufacturers’ WARNINGS, instructions and

procedures concerning sprayer system cleaning.

3.5 MECHANICAL FIELD OPERATION AND ADJUSTMENT

. OPEN TO FIELD POSITION

a. Remove transport clevis pins.

b. Unfold booms to field position one side at a time. On windshield sprayers, the pin that pre-

vents the part one from folding up is easiest to install if it is done after the booms have been

released from the transport rest and before the part two is unfolded.

c. Unlock swinging center beam to allow free movement from side to side.

IMPORTANT!

WHEN FOLDING AND DURING TRANSPORT THE CENTER BEAM SWING LOCKS MUST BE

LOCKED TO PREVENT THE CENTER BEAM FROM MOVING. WHEN SPRAYING, THE CEN-

TER BEAM MUST BE UNLOCKED TO ALLOW PROPER FLOATING BOOM OPERATION.

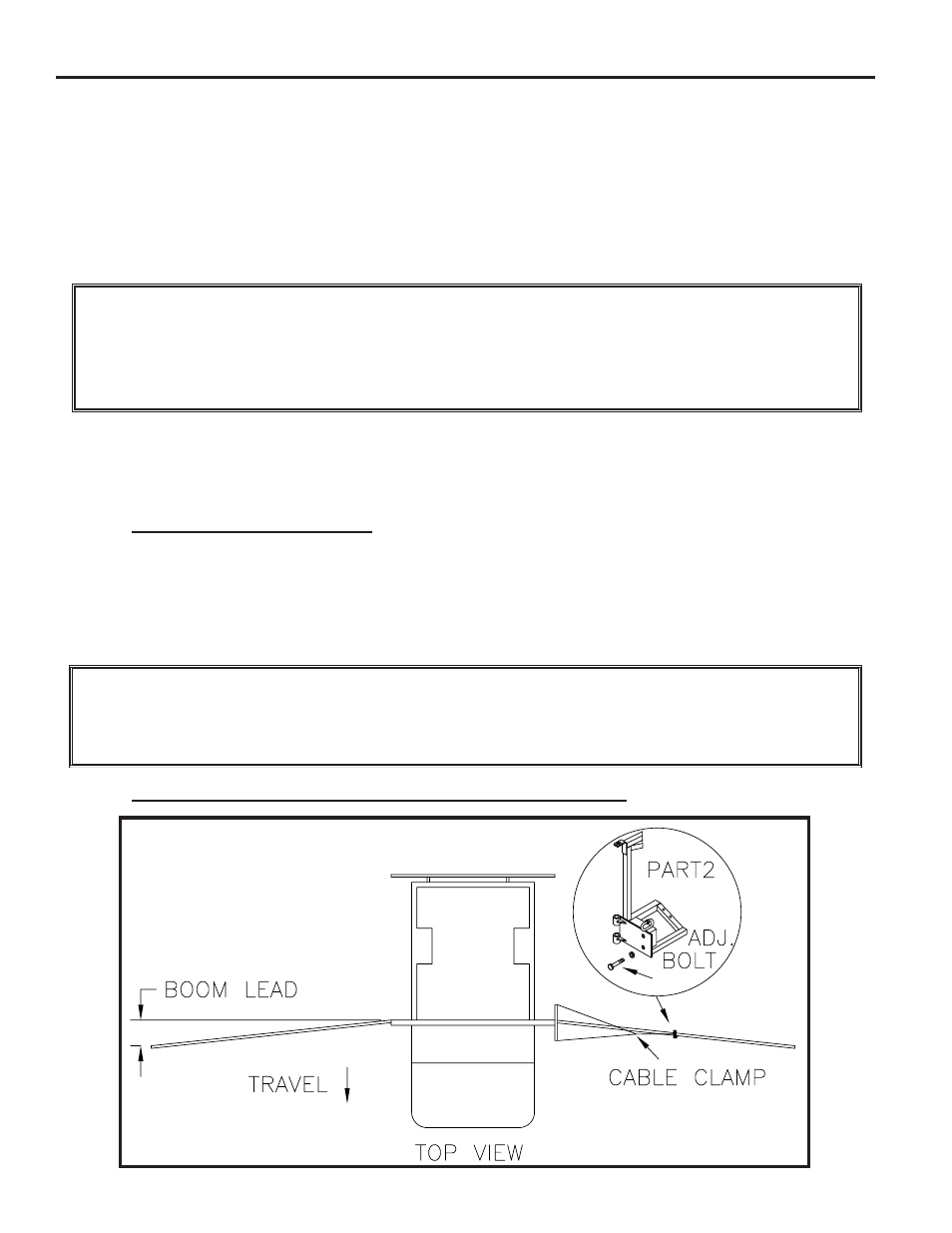

2. SETTING BOOM LEAD ON CABLE SUSPENDED BOOMS