Summers Truck Supersprayer User Manual

Page 17

SECTION 3 - SPRAYER OPERATION

3.3

3. LOAD SPRAYER

A. TRUCK MOUNTED SPRAYER

1. Retract jacks and remove. Lift rear of sprayer and pin legs in the up position.

2. Secure Skid with rear box locks provided at the two corners.

3. Make wiring connections per diagram on page 15.

a. one battery positive connection.

b. one battery switched and fused connection.

c. one ground connection.

4. To connect tip lift electrical system to pickup electrical system follow these steps:

a. Attach ground cable to the hole in pickup box using a 3/8” bolt and nut.

b. Route power cord to engine compartment and connect to positive battery terminal

or main battery power distribution source.

c. Connect single small RED wire to a SWITCHED and FUSED terminal in the

pickup fuse box. This may require additional wire.

WARNING!

POWER CORD MUST NOT CONTACT EXHAUST OR MOVING PARTS. THE CABLE

HAS NO CIRCUIT PROTECTION AND ANY DAMAGE TO THE CABLE INSULATION

COULD RESULT IN PERMANENT BATTERY DAMAGE.

CAUTION!

DO NOT CONNECT RED WIRE TO ANY NON-SWITCHED TERMINAL. AN INCOR-

RECT POWER SUPPLY WILL PERMIT TIP LIFT OPERATION AT ANY TIME WITHOUT

THE IGNITION SWITCH IN THE ON POSITION AND COULD RESULT IN SERIOUS

BODILY INJURY OR DAMAGE TO THE SPRAYER.

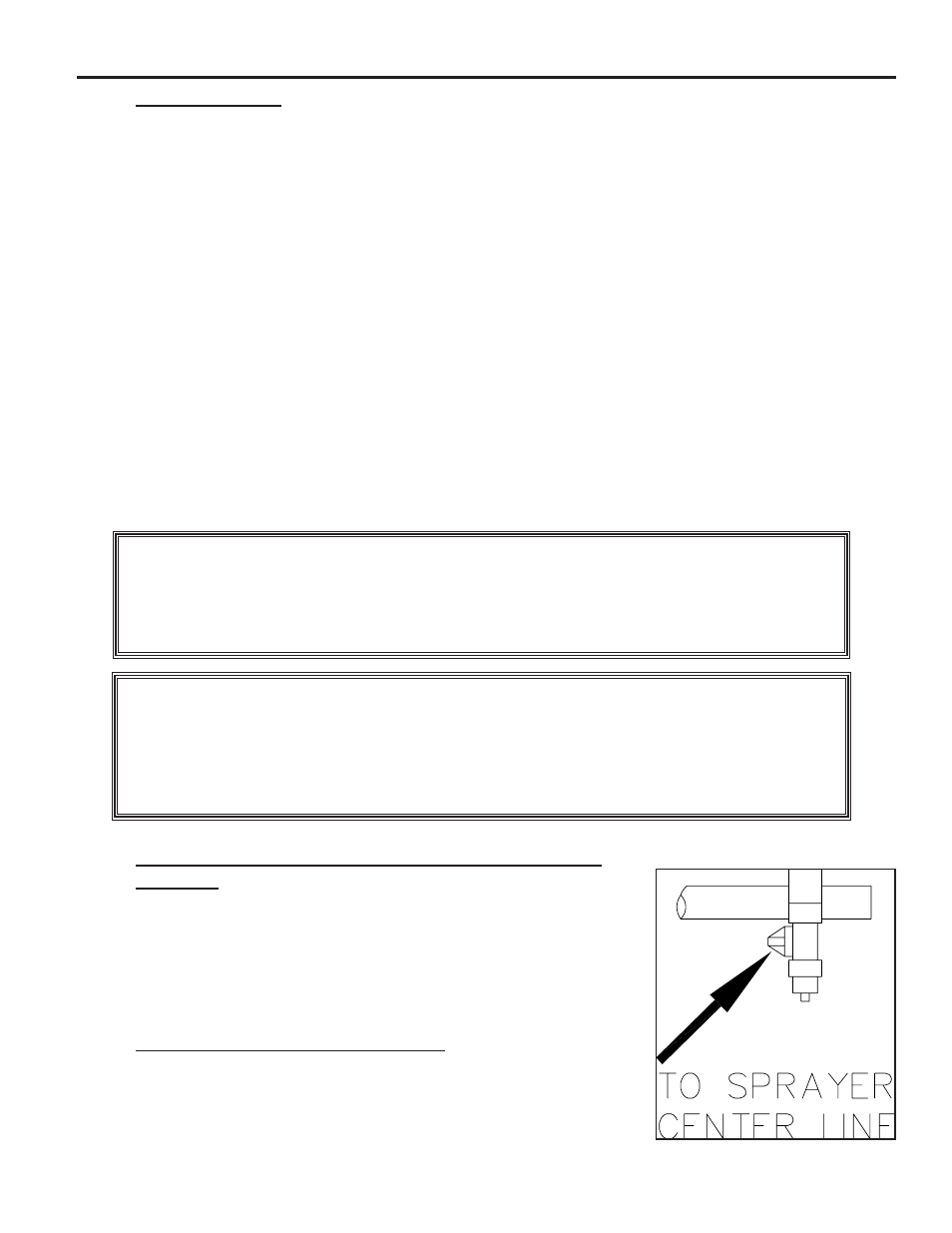

4. 60 TO 90 FOOT CABLE SUSPENDED BOOM NOZZLE

SPACING

Nozzle spacing for the Summers wet boom field sprayers is 20

inches with equal distance from sprayer centerline. The first noz-

zle is 10 inches from the sprayer centerline on rear center boom

with each consecutive nozzle in 20 inch increments.

5. NOZZLE TO BOOM ORIENTATION