Initial setup of spray system – Summers Truck Supersprayer User Manual

Page 18

SECTION 3 - SPRAYER OPERATION

3.4

6. WET BOOM ROTATION ADJUSTMENT

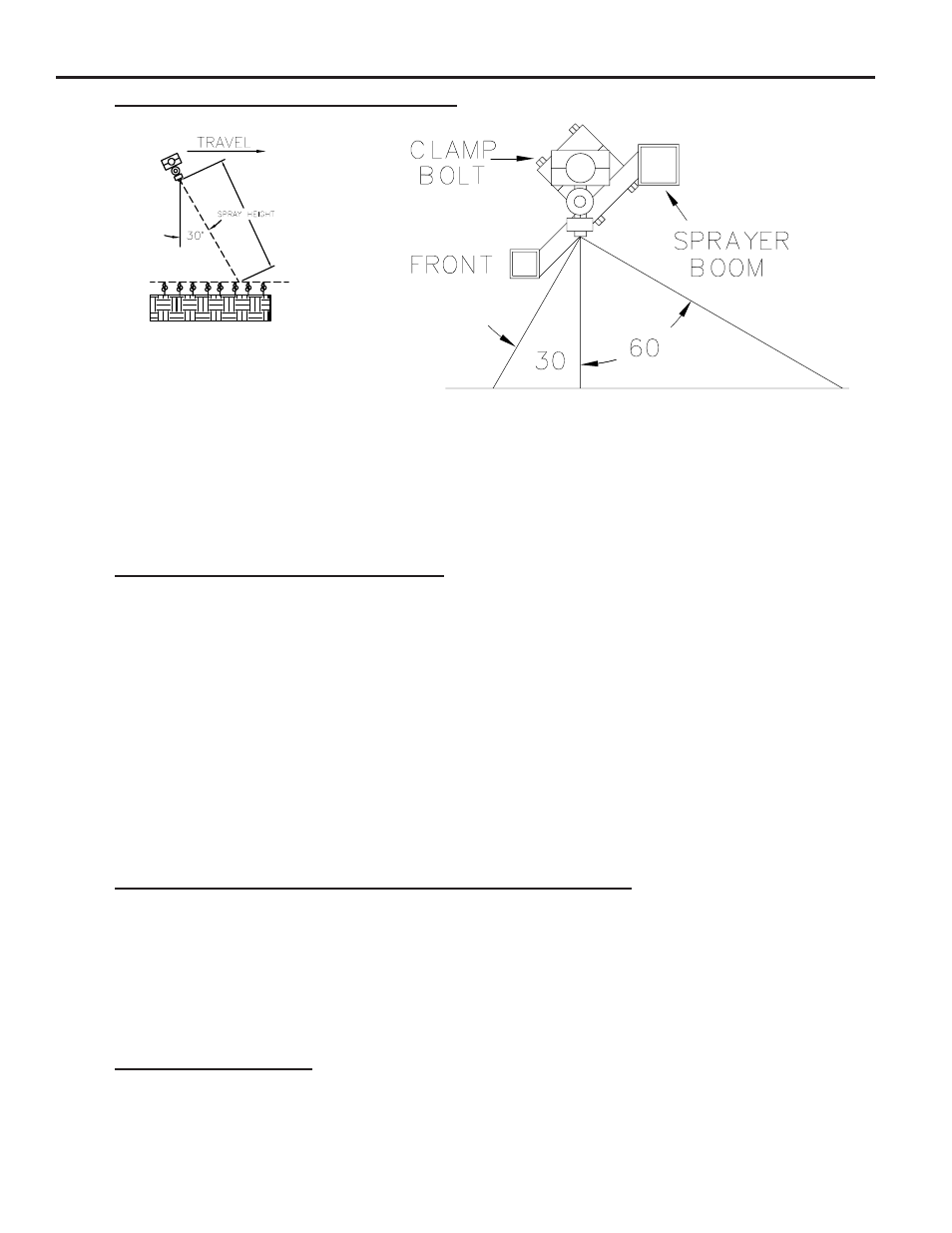

The wet boom can be rotated from 30 degrees forward to 60 degrees rearward depending on opera-

tor preference. The factory setting is vertical. To perform a rotation adjustment, loosen clamp bolts

securing wet boom and rotate nozzles to desired setting. With the booms in position tighten all the

holding hardware to maintain the proper nozzle space setting between the rear center boom and side

booms.

7. CONNECTING SPRAYER CONTROLS

Follow the wiring diagram below to properly connect the electronic controls of your Summers

sprayer. Attach appropriate wire leads to the electronic ball valves. The remaining leads may be

used for connecting electric end nozzles, any unused leads should be taped back to the harness. See

your Raven instruction manual for additional information on the sprayer control or electronic flow-

meter and pressure regulator valves.

SCS-205 Control has Mechanical Pressure Sensing (Less Pressure Transducer).

12’ extension cable assemblies are available.

Order PN 8A1285 for SCS-205 Control.

Order PN 8A4340 for SCS-450 Control.

8. ELECTRIC - HYDRAULIC TIP LIFT ON TRUCK SPRAYERS

The electric-hydraulic tip lift is a self-contained hydraulic system. It requires little maintenance other

than clean oil filled to the proper level, a good 12-volt power source, and a secure ground.

3.3 INITIAL SETUP OF SPRAY SYSTEM

. DETERMINE TIP SIZE

Determine tip size by examining a nozzle tip for the stamped number.